Method for alleviating nano zero-valent iron passivation

A nano-zero-valent iron and zero-valent iron technology, applied in the field of materials, can solve the problems of high energy consumption, complex operation, difficult to use on a large scale, and achieve the effects of low energy consumption, simple operation, alleviation and promotion of degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Embodiment A method for alleviating the passivation of nanometer zero valent iron

[0034] Step 1. Preparation of nanometer zero-valent iron and its use in reductive dechlorination of chlorinated organics

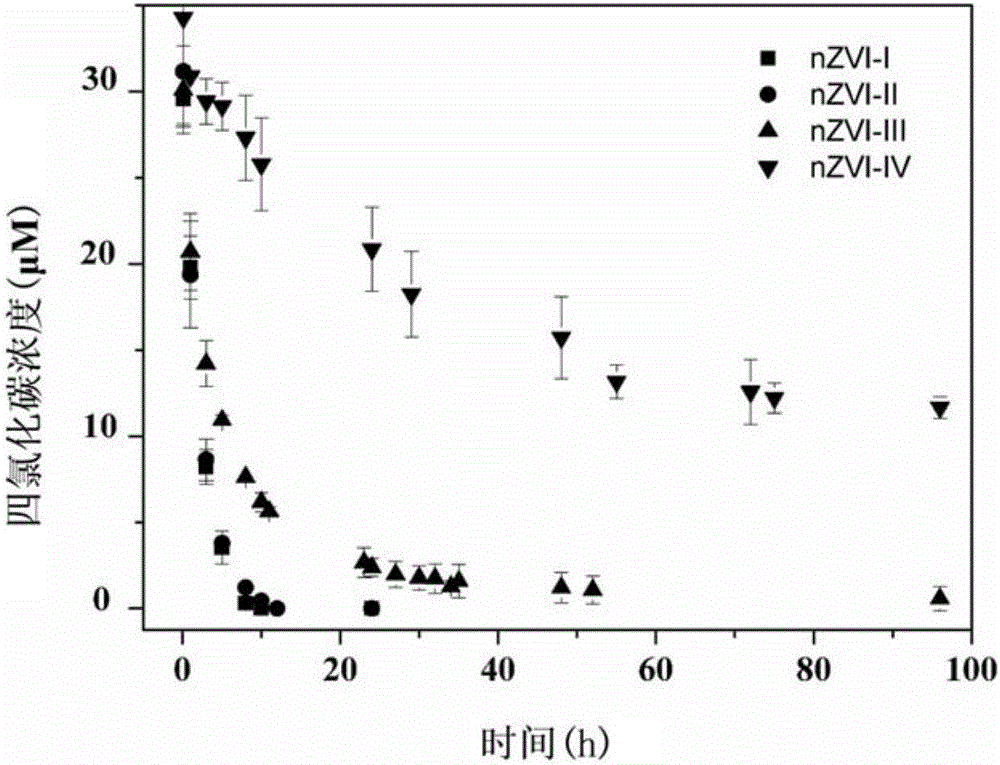

[0035] The nanometer zero-valent iron is prepared by a chemical precipitation method by adopting ferric salt and borohydride, and the obtained product is dried and preserved. Add 50 mg of nanometer zero-valent iron to an anaerobic vial containing 100 mL of carbon tetrachloride (35 μM), place it in a shaker, and carry out dechlorination reaction at 30 ° C and 180 rpm, and take samples at specific time points, and use Gas chromatograph detects carbon tetrachloride; Treat that carbon tetrachloride degrades completely, add 35 μ M carbon tetrachloride again and continue the degradation reaction of next cycle, run continuously for four cycles (see figure 1 ). figure 1 It shows that after several cycles of dechlorination reaction, the reactivity of nanometer zero-valent i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com