A tool clamping device

A technology of tool clamping and tooling, applied in the direction of positioning device, clamping, manufacturing tools, etc., can solve the problems of tool dropping, complex structure of clamping method, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

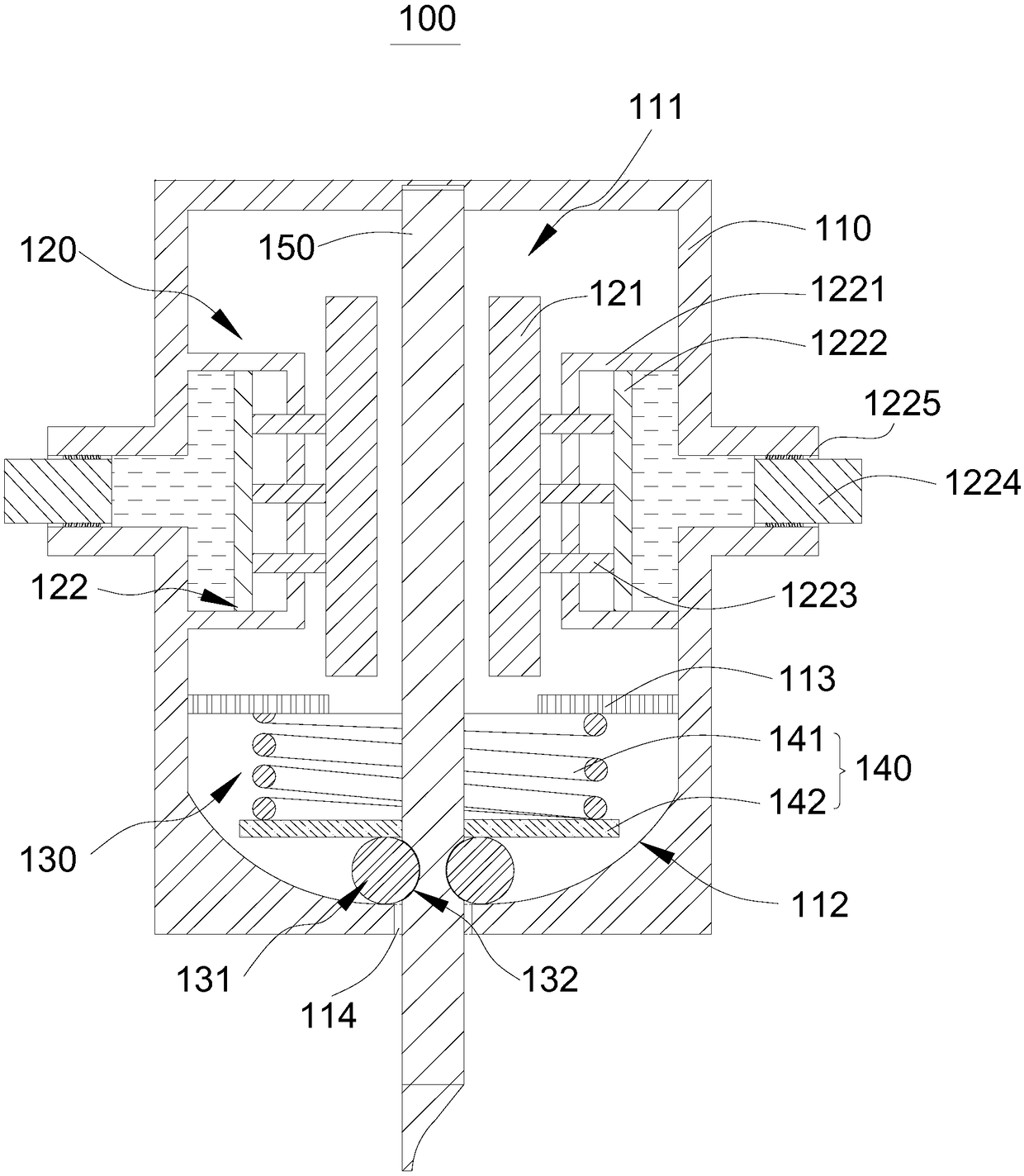

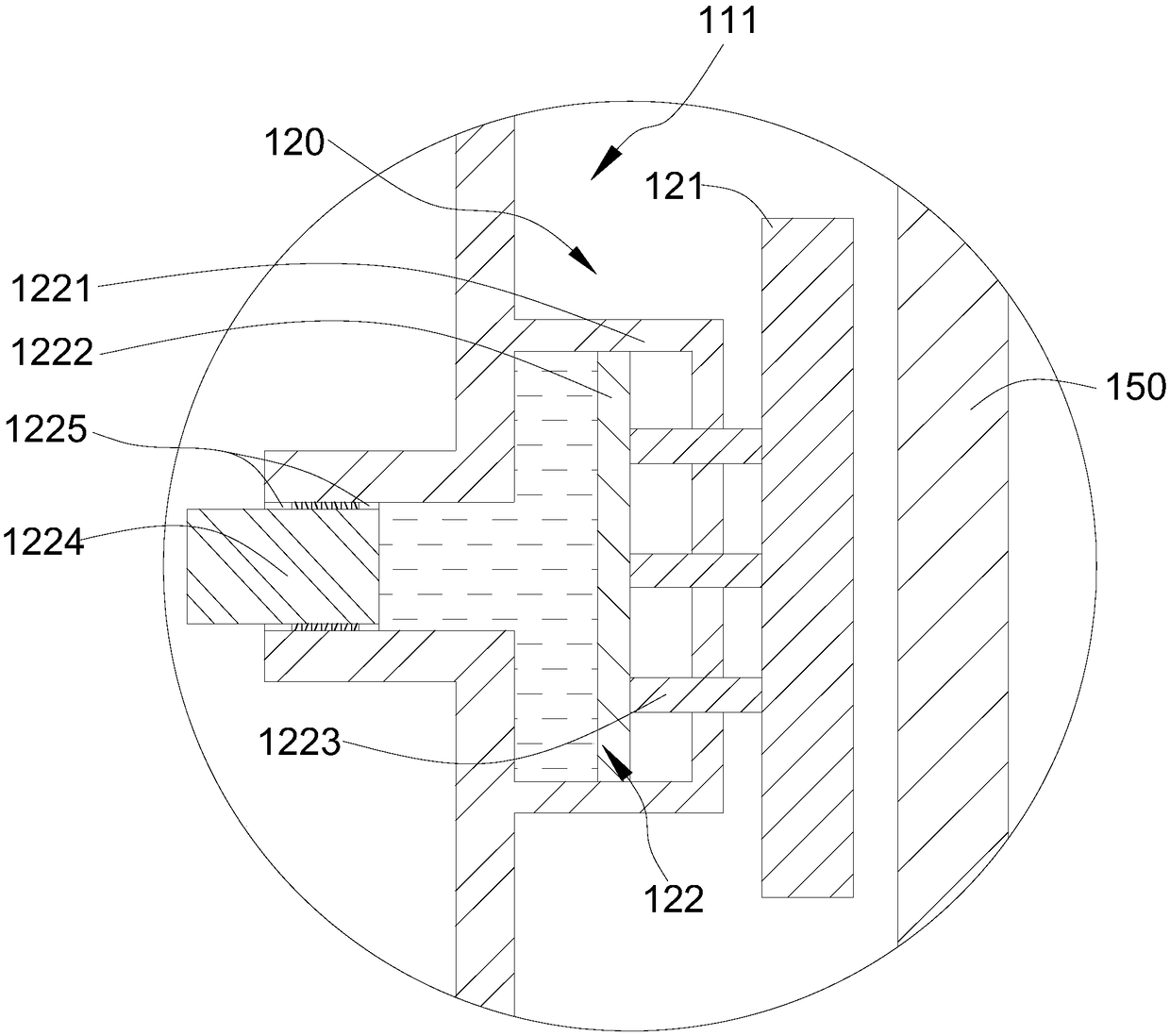

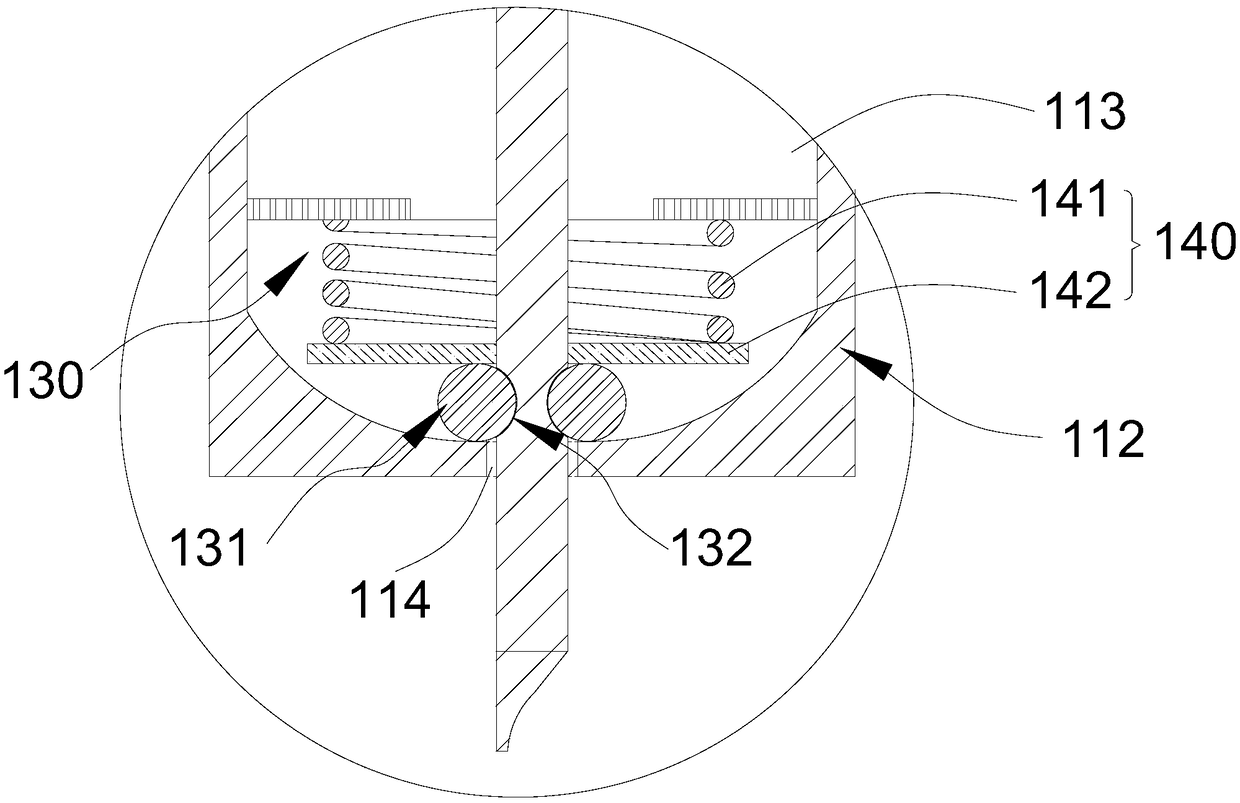

[0042] Please refer to figure 1 , figure 1 is a cross-sectional view of the tool clamping device 100 . This embodiment provides a tool clamping device 100 , which includes a body 110 , a first limiting portion 120 for limiting the displacement of the tool 150 in the radial direction, and a second limiting portion 130 for limiting the displacement of the tool 150 in the axial direction.

[0043] The main body 110 has an accommodating space 111 with one end open, and the inner wall of the accommodating space 111 closes to the center of the opening to form a passage hole 114 for the cutter 150 to pass through. In this embodiment of the present invention, the body 110 is a cylindrical structure, and a cylindrical inner cavity is opened in the center of the main body 110, and the cylindrical inner cavity is the accommodating space 111; one end of the cylindrical inner cavity is opened, and the cylindrical inner cavity The inner wall of the cavity closes to the center of the openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com