Screw-tightening mechanism for case shell and case assembly system

A chassis shell and screwing technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as troublesome use, reduced work efficiency, and no power supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings of the description:

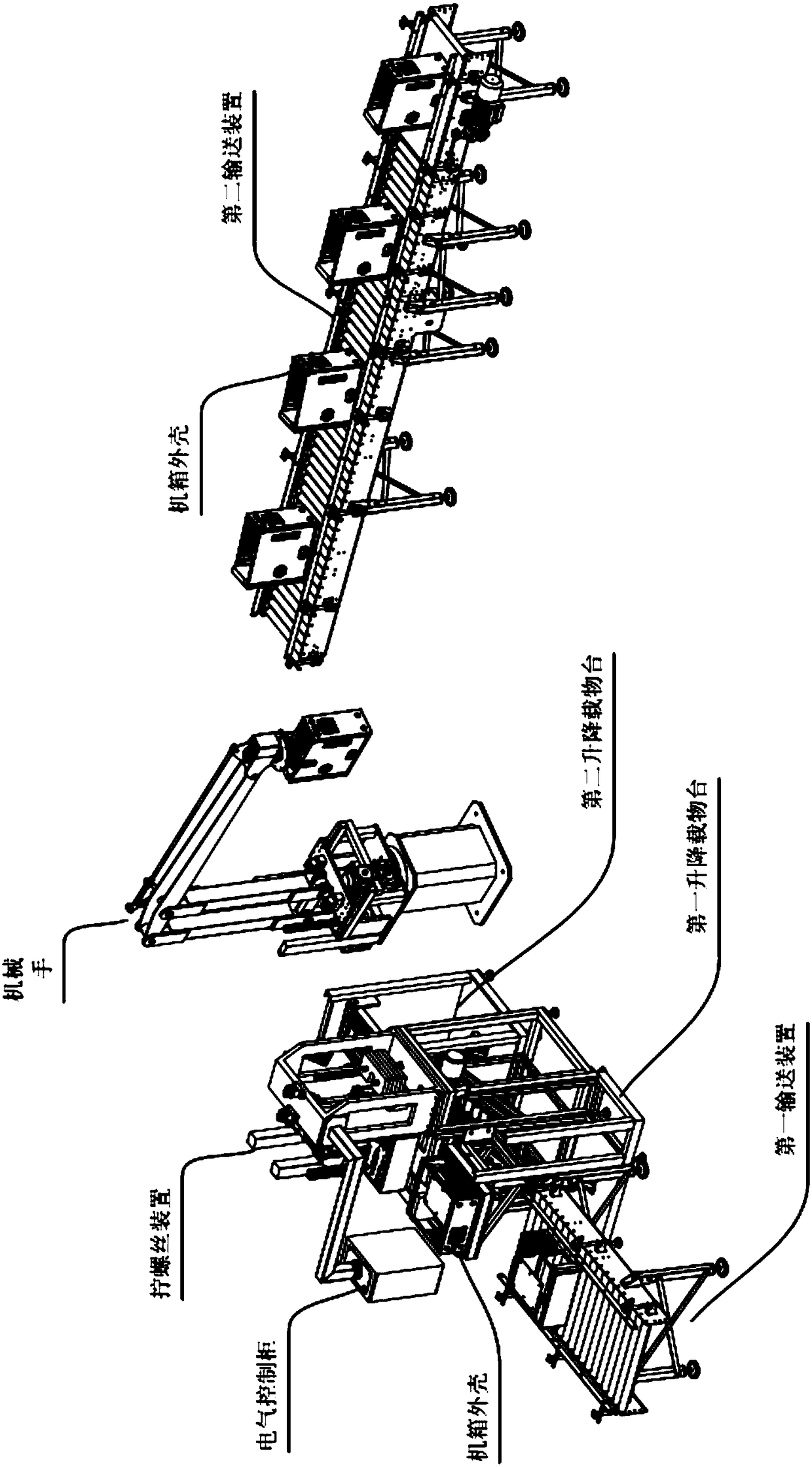

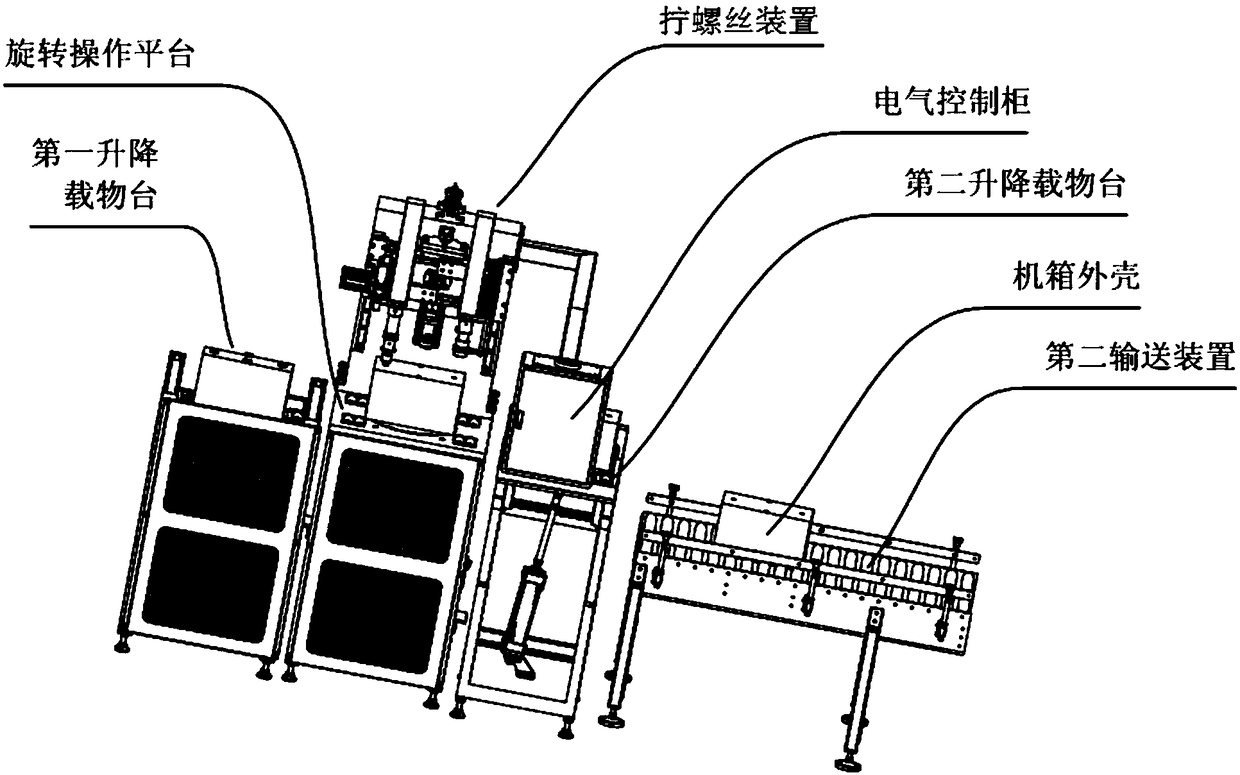

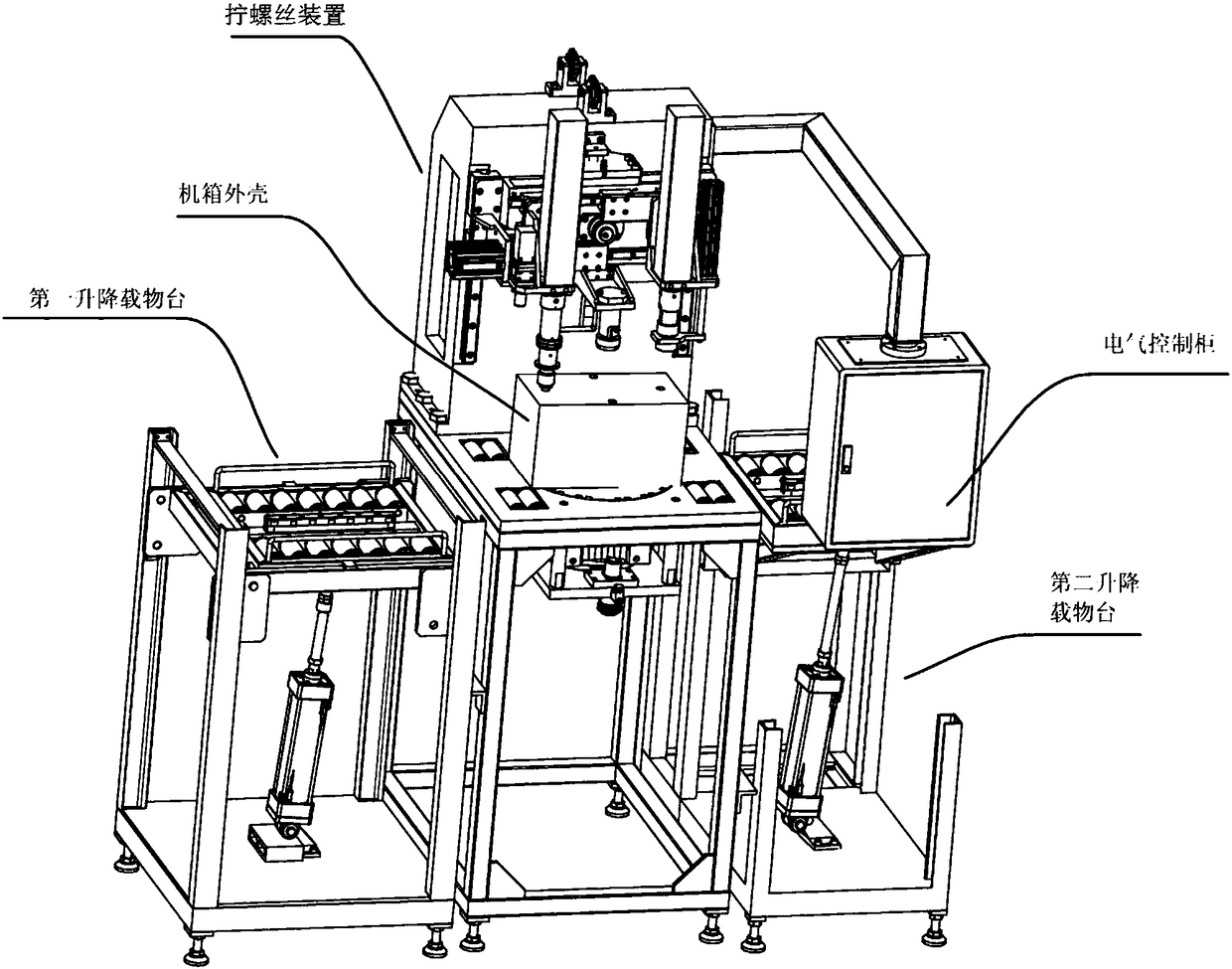

[0057] like Figure 1-23 As shown, the present invention proposes a specific embodiment of a screw-screwing mechanism for a chassis shell. A screw-screwing mechanism for a chassis shell includes a first lifting stage, a screwing device, a second lifting stage, a rotating operating platform, and a chassis shell The conveying device and the electrical control cabinet, wherein: the first lifting stage is used to lift the chassis shell to be processed to a predetermined height and transport it to the workbench of the screwing device; Lift and convey the chassis shells to be processed for screwing; the second lifting stage is used to receive the screwed chassis shells, and lift or lower these chassis shells to a predetermined height to enter the conveying station; rotating operation The platform is used to adjust the chassis shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com