A hydraulic disassembly equipment and method specially used for large valves

A valve and hydraulic technology, applied in the field of hydraulic disassembly and assembly equipment for large valves, can solve the problems of inconvenient disassembly of the installation location, high safety risks, and difficulty in replacement, and achieve improved technology and management level, high safety, and production downtime. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments.

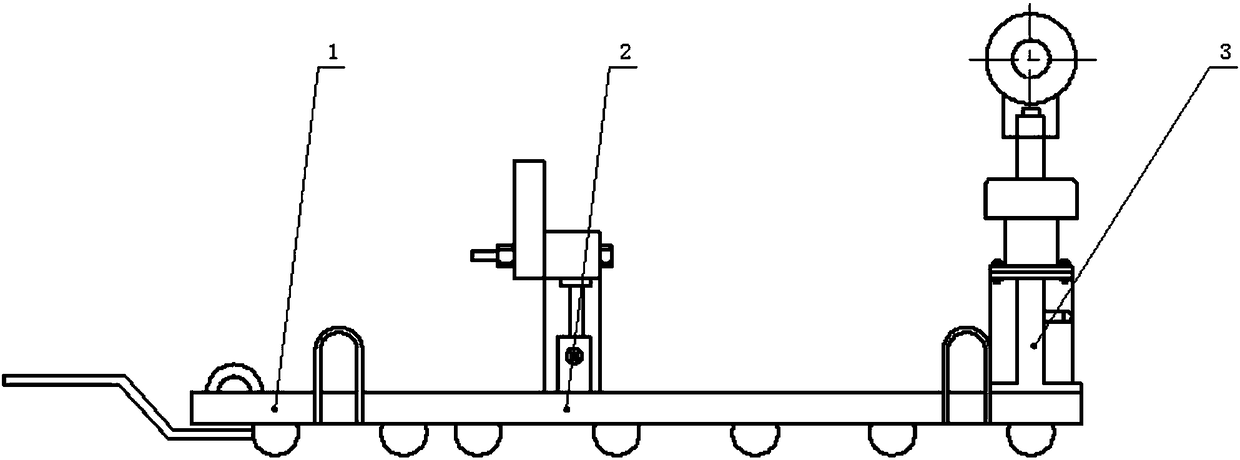

[0035] A hydraulic disassembly and assembly equipment dedicated to large valves, such as figure 1 As shown, it includes a mobile plate assembly 1, an end flange support assembly 2, and a lifting lug hydraulic support assembly 3. The end flange support assembly is installed on one side of the upper part of the mobile plate assembly, and the lifting lug hydraulic pressure The support component supports and fixes the valve through two sets of support components, and the translation of the valve is realized by moving the plate component.

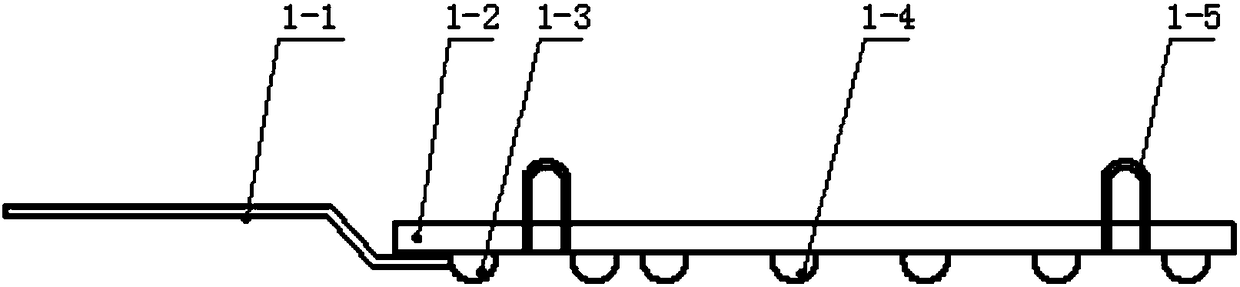

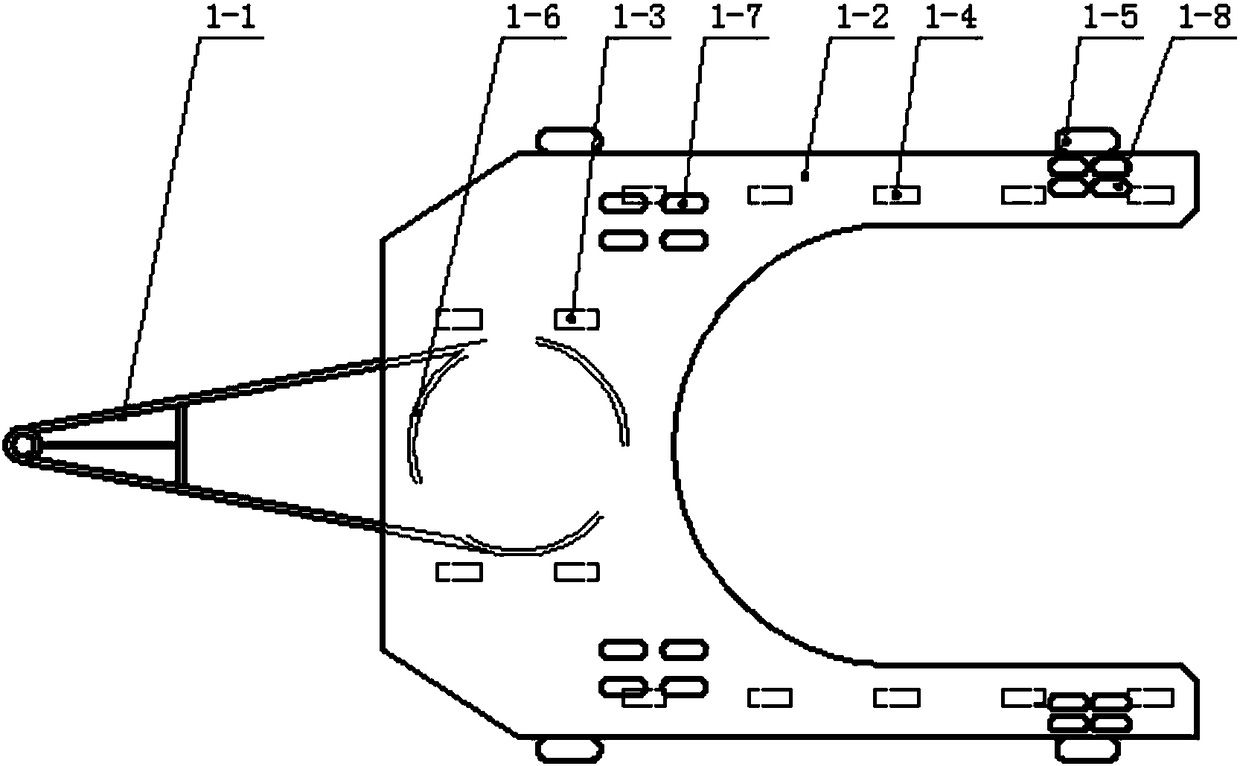

[0036] In this embodiment, the structure of the mobile panel assembly is as follows figure 2 , image 3 As shown, it includes a pallet 1-2 and a traction frame 1-1. The pallet is a U-shaped structure, and its front end is equipped with a traction frame through a slewing support 1-6, and four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com