Nut automatic loading and unloading system, nut closing machine and nut closing method

A closing machine and nut technology, applied in nuts, mechanical equipment, threaded fasteners, etc., can solve the problem of time-consuming and laborious loading and unloading process, and achieve the effect of avoiding time-consuming, labor-intensive and accurate closing operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

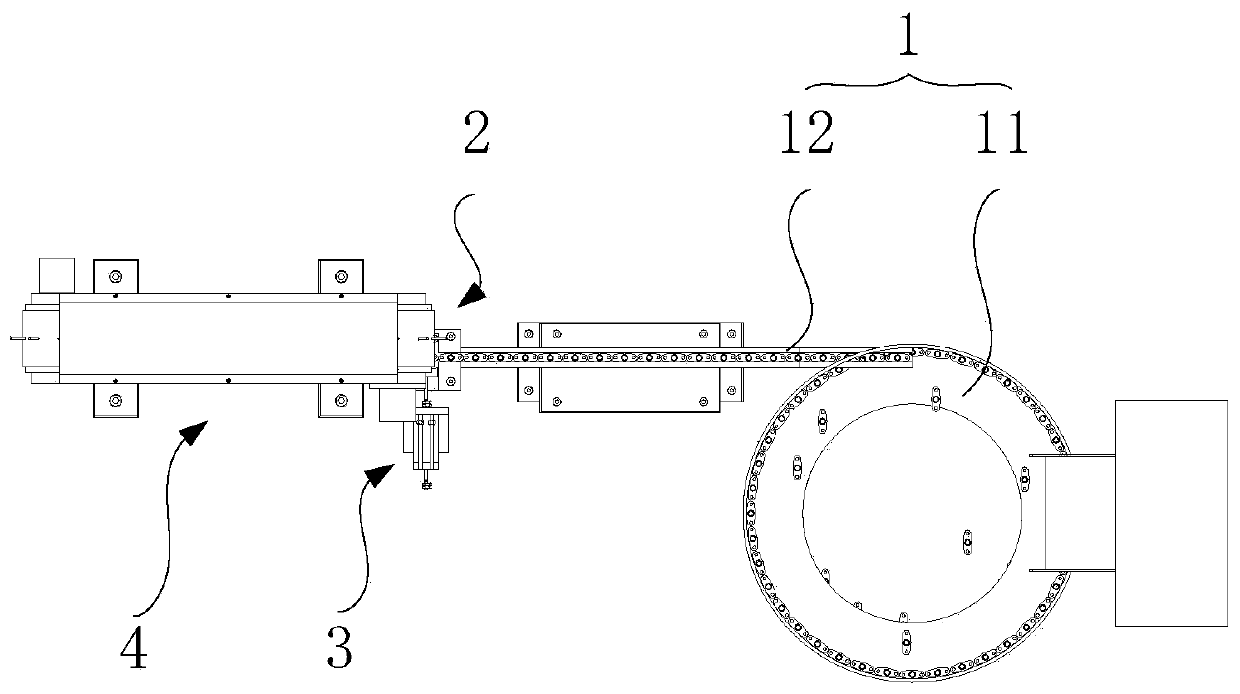

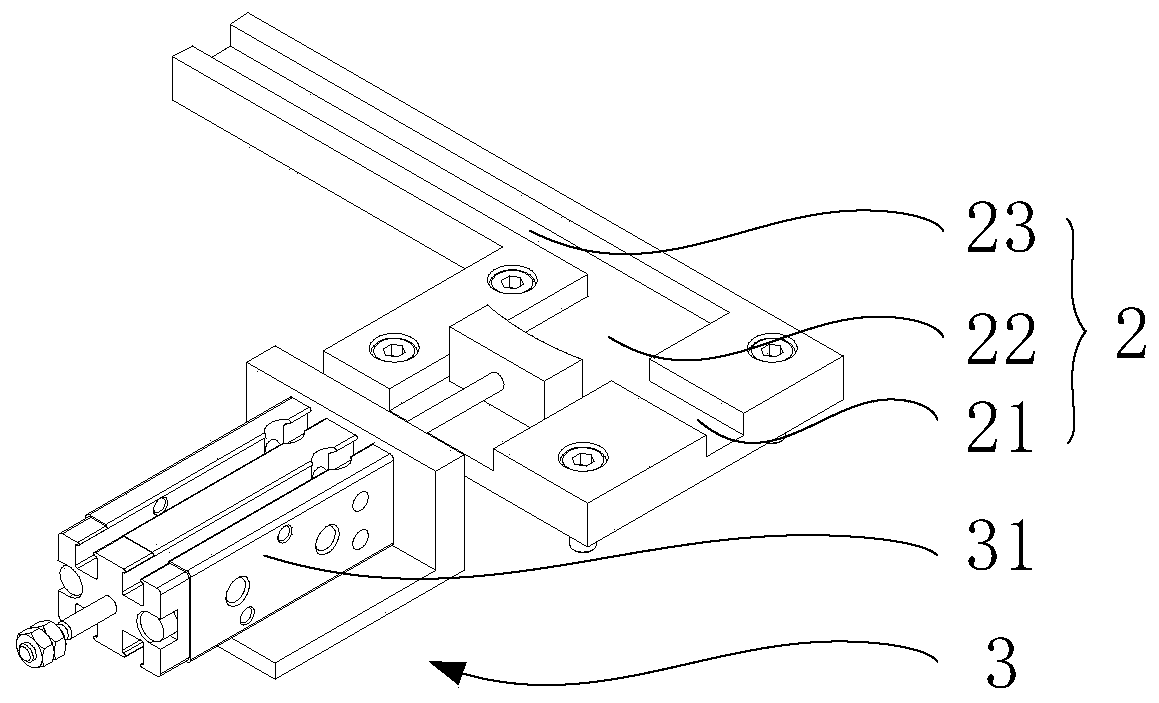

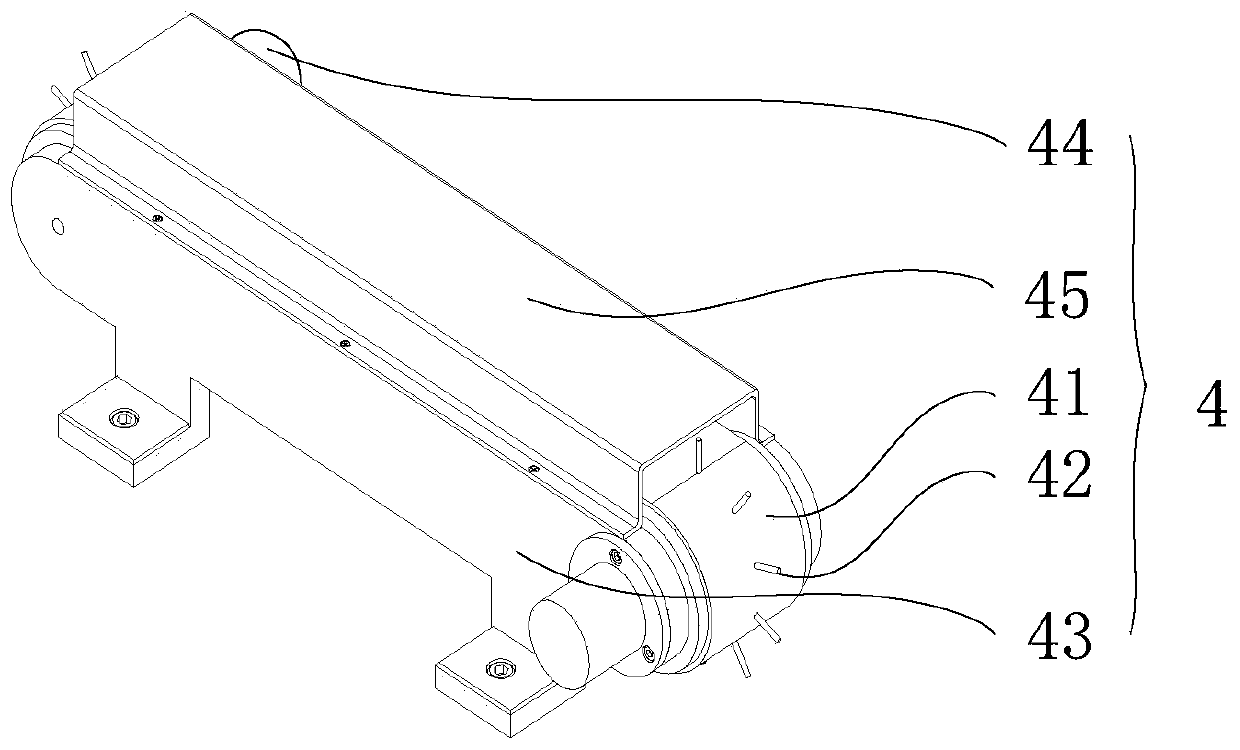

[0040] The purpose of this embodiment is to provide a nut automatic loading and unloading system, such as Figure 1 to Figure 3 As shown, it includes a feeding device 1, a transportation track 2, a first transportation device 3 and a second transportation device 4, wherein: the discharge port of the feeding device 1 cooperates with the feeding port of the transportation track 2 to transport the nuts in an orderly manner Transport track 2; transport track 2 comprises the first track 21 that the feed port cooperates with the discharge port of the feeding device 1, the second track 22 that the feed port cooperates with the discharge port of the first track 21 and the feed port cooperates with the first track 21. The third track 23 that the discharge opening of two tracks 22 cooperates; Push one nut at a time; the second transportation device 4 includes a belt 41 arranged above the third track 23, and a plurality of driving rods 42 are arranged at intervals on the belt 41, and the...

Embodiment 2

[0051] The purpose of this embodiment is to provide a nut closing machine, which adopts the nut automatic loading and unloading system disclosed in the first embodiment. In order to save space, the relevant technical features of the nut automatic loading and unloading system disclosed in the first embodiment are not repeated Repeat the description, specifically:

[0052] like Figure 4 As shown, the nut closing machine provided by the present invention includes the above-mentioned nut automatic loading and unloading system, but the nut closing machine of the prior art does not have an automatic loading and unloading system, and is in the stage of manual loading and unloading, which has poor adaptability, time-consuming and laborious And other issues. Compared with the prior art, the nut closing machine provided by the present invention has an automatic loading and unloading system, which does not need manual loading and unloading of nuts, and can quickly and accurately realiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com