Industrial tail gas purification treatment and haze prevention device

A technology for purifying and treating industrial exhaust gas, which can be applied to combined devices, climate change adaptation, and climate sustainability. Human, reducing disease, eliminating smog effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

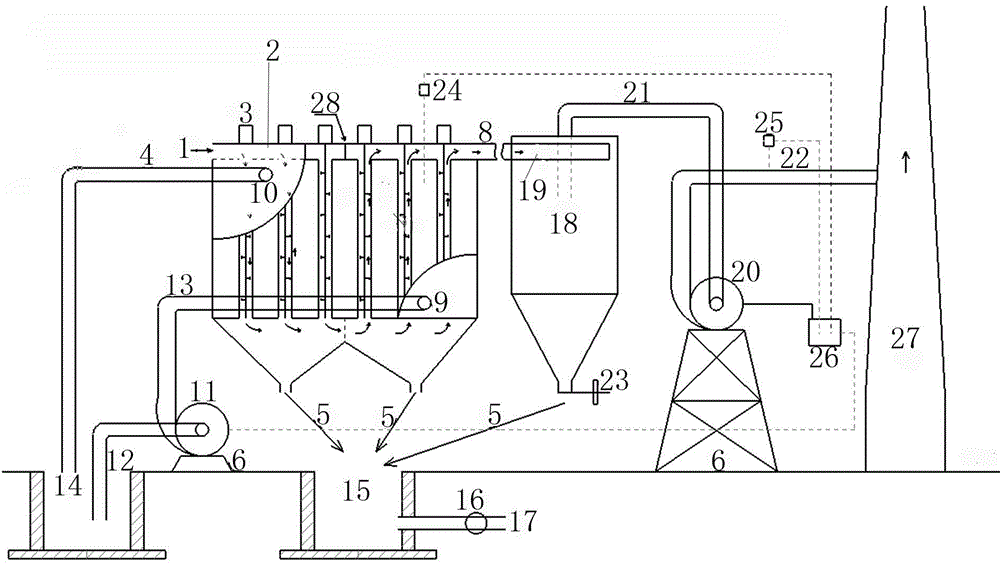

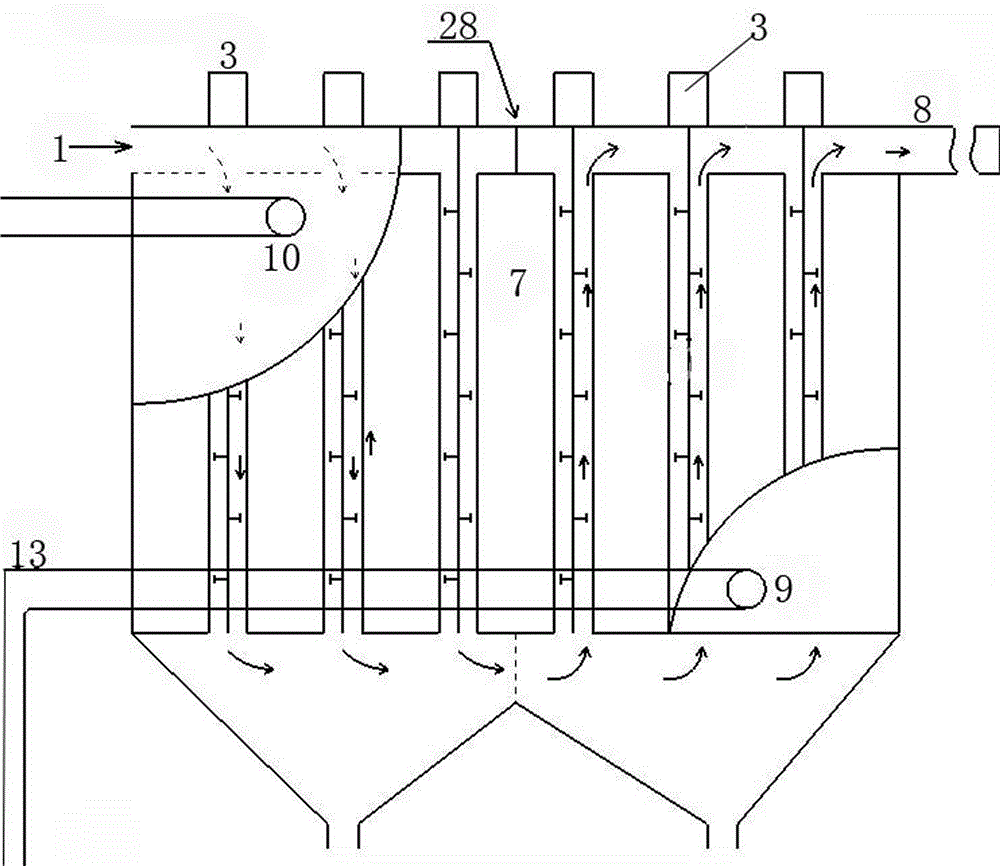

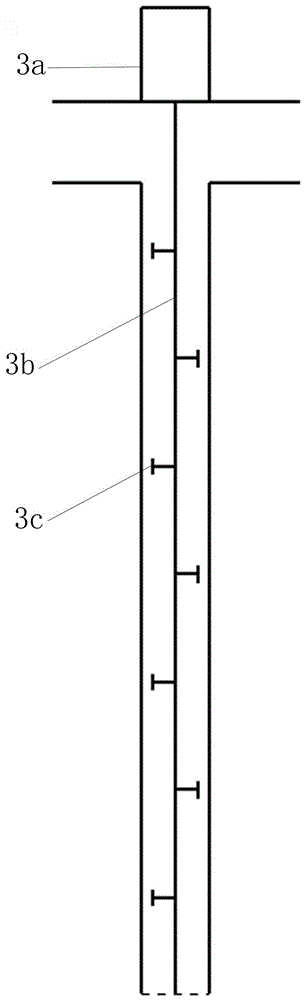

[0025] An industrial tail gas purification treatment and anti-fog device, including at least one steam cooler group 2; each steam cooler group 2 includes a shell with at least three cooling pipes 7 arranged in sequence and spaced from each other, the cooling pipes 7 There is a gap between the top and the top of the shell to form a gas inlet / exhaust channel, and the side walls of the shell are respectively opened with openings communicating with both ends of the gas inlet / exhaust channel, one of which is used as an air inlet for receiving external steam 1 , and the other is used as the cooling and purifying gas outlet 8; there is a gap between the bottom of the cooling tube 7 and the bottom of the shell to form a bottom gas passage; The inner walls of adjacent shells are sealed and connected; the interval between adjacent cooling pipes 7 and the inner walls of the shells on both sides of the interval jointly form an ascending / descending air channel; a cooling pipe 7 top located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com