Ficus carica leaf enzyme and preparation method thereof

A technology of fig leaves and figs, applied in the field of fig leaf enzymes and its preparation, can solve the problems of less utilization of fig leaves, waste of resources, low utilization degree, etc., achieve great economic and environmental benefits, save resources, and lower production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

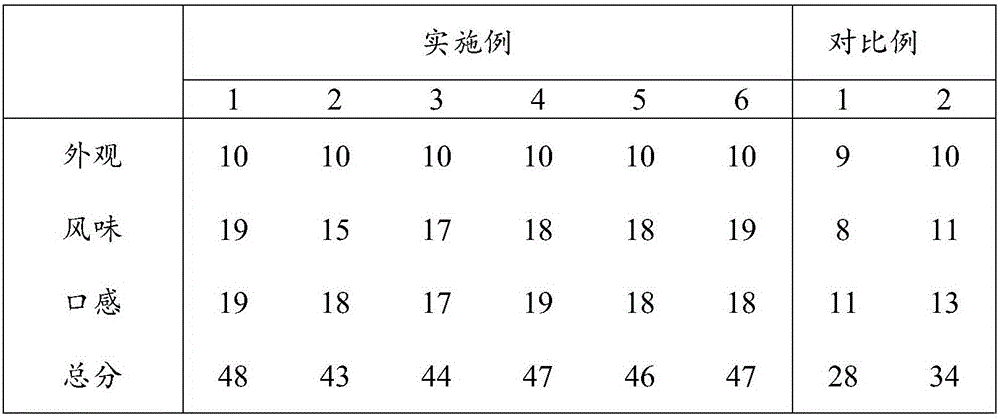

Examples

preparation example Construction

[0016] A kind of preparation method of fig leaf ferment that the embodiment of the present invention provides, comprises the following steps:

[0017] The production of fig leaf enzyme is carried out with fresh fig leaves as the main material. The fig tree is a pest-free cultivated fruit tree that does not need to be sprayed with pesticides at present. Its fruits and leaves will not be damaged by insects, and there is no need to spray pesticides during the cultivation process. Therefore, the yield of figs and fig leaves is high, the quality is good, and there is no pesticide residue. The prepared fig leaf enzyme is green, safe, environmentally friendly and healthy.

[0018] Preferably, the tender fresh leaves on the fig tree are picked as raw materials for production. Compared with old leaves, fresh leaves have higher water content, higher tenderness, rich content of nutrients such as amino acids, vitamins, sugars, etc. During the fermentation process, the nutrients of fresh ...

Embodiment 1

[0035] A fig leaf enzyme provided in this example is prepared according to the following steps.

[0036] First, fresh fig leaves are washed and put into a vacuum pulverizer for pulverization. Add the pulverized fig leaves, fig fermented grains and water into the mixing tank according to the weight ratio of 3:1:3, and stir for 120 minutes under vacuum condition.

[0037] Then, pump the mixed material into the fermenter, seal the fermenter, and ferment at 10°C. After 280 days of fermentation under vacuum conditions, the primary fermentation product was obtained, and the primary fermentation product was subjected to coarse filtration to obtain the primary fermentation liquid. Under vacuum conditions, the initial fermentation broth was left to stand for 50 days in a closed fermentation tank, then left to stand for 20 days of fermentation after the first fine filtration, and then left to stand for 10 days of fermentation after the second fine filtration to obtain the fig leaf enzy...

Embodiment 2

[0039] A fig leaf enzyme provided in this example is prepared according to the following steps.

[0040] First, fresh fig leaves are washed and put into a vacuum pulverizer for pulverization. Add the pulverized fig leaves, fig fermented grains and water into the mixing tank according to the weight ratio of 5:1:7, and stir for 100 minutes under vacuum condition.

[0041] Then, pump the mixed material into a fermenter, seal the fermenter, and ferment at 5°C. After fermenting for 300 days under vacuum condition, the first fermented product is obtained, and the first fermented product is subjected to rough filtration to obtain the first fermented liquid. Under vacuum conditions, the initial fermentation liquid was left to stand for 40 days in a closed fermentation tank for fermentation, followed by the first fine filtration and then continued to stand for 15 days of fermentation, followed by the second time of fine filtration and then left for 5 days to obtain the fig leaf enzyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com