Preparation method of super-hydrophobic graphene/polyurethane sponge

A technology of polyurethane sponge and graphene, applied in the research field of superhydrophobic composite materials, can solve problems such as process resumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

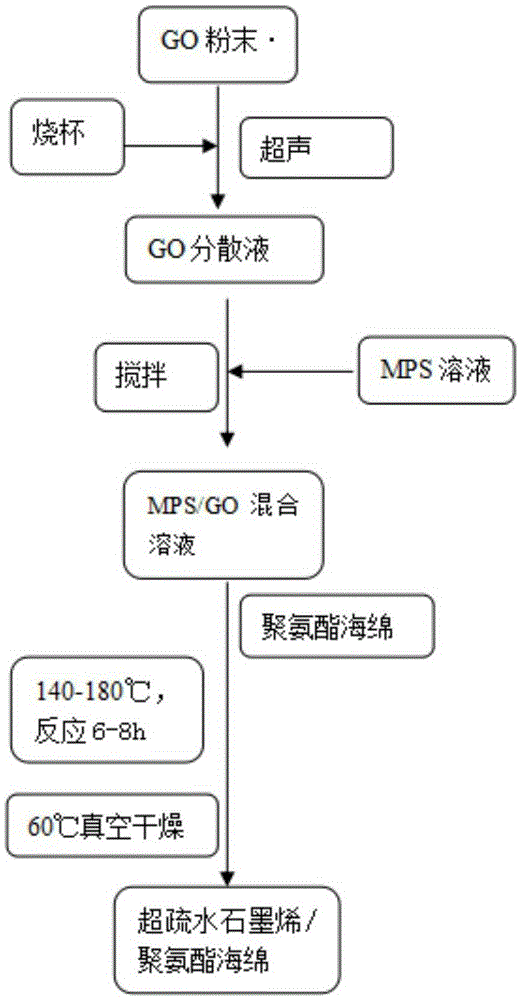

[0018] A kind of preparation method of superhydrophobic graphene / polyurethane sponge, its flow process is as follows figure 1 , including the following steps:

[0019] (1) Simplified graphite (GO) was added to deionized water, and ultrasonically dispersed for 30 minutes to obtain uniformly dispersed water, and the concentration of simplified graphite in the dispersed water was controlled to 1-5 mg / mL.

[0020] (3) Calculated according to the mass ratio, that is, the ratio of GO: MPS is 0.3:1-30:1, the MPS water is added to the obtained GO dispersion water, stirred for 1 hour, and the mixed water that is fully stirred is moved to the In the kettle, seal the polymer, control the temperature and heat it at 90-100°C for 4-8h, and heat the product at 50°C to obtain a superhydrophobic graphene / polyurethane sponge.

[0021] (4) On the surface of the prepared superhydrophobic graphene / polyurethane sponge, drop deionized water to test the contact angle.

Embodiment 1

[0023] Add 30mg of simplified graphite (GO) into a beaker with 10mL of deionized water, and ultrasonicate for 30min to obtain uniformly dispersed water. Transfer 100 uL of MPS water to the beaker containing GO water and stir for 1 h. Simply transfer the fully stirred mixed water to a reaction kettle, seal the polymer, control the temperature and heat it at 100°C for 8 hours, and vacuum the product at 50°C to obtain a superhydrophobic graphene / polyurethane sponge.

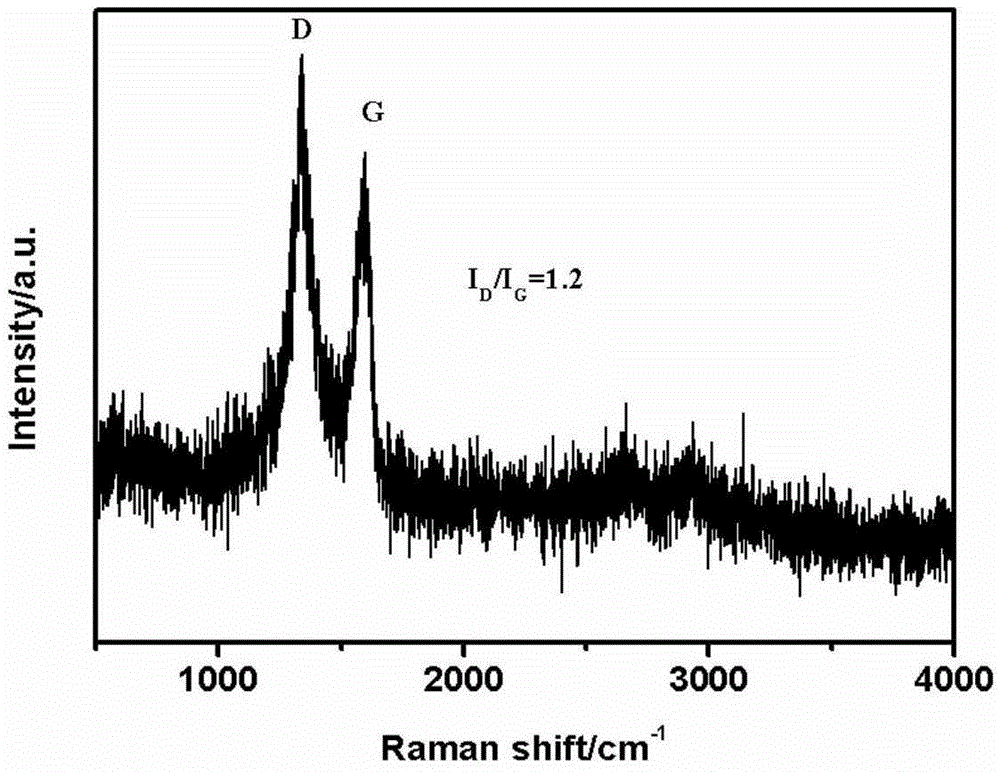

[0024] The Raman spectrogram of the superhydrophobic graphene / polyurethane sponge prepared in above-mentioned embodiment 1, as figure 2 As shown, I D / I G =1.2, indicating that the simplified graphite was reduced to graphene.

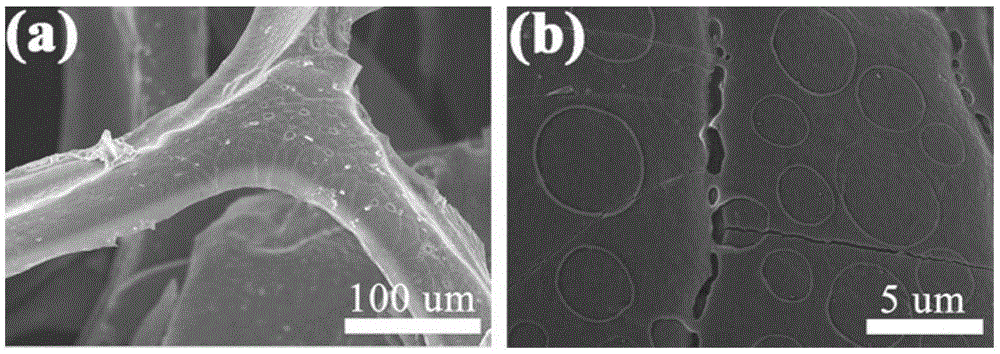

[0025] The scanning electron micrograph of the superhydrophobic graphene / polyurethane sponge prepared in above-mentioned embodiment 1, as image 3 As shown, on the surface of the polyurethane sponge, the graphene sheet is evenly covered but can be energized.

[0026] The water contact a...

Embodiment 2

[0028] Add 30mg of simplified graphite (GO) into a beaker with 10mL of deionized water, and ultrasonicate for 30min to obtain uniformly dispersed water. Simply transfer 10 uL of MPS water to the beaker containing GO water and stir for 1 h. Simply move the fully stirred mixed water to a reaction kettle, seal the polymer, control the temperature and heat it at 95°C for 6 hours, and vacuum the product at 50°C to obtain a superhydrophobic graphene / polyurethane sponge.

[0029] The Raman spectrogram of the superhydrophobic graphene / polyurethane sponge prepared in above-mentioned embodiment 2, its I D / I G >1.1, indicating that simplified graphite is reduced to graphene.

[0030] The scanning electron micrograph of the superhydrophobic graphene / polyurethane sponge prepared in the above-mentioned embodiment 2, on the surface of the polyurethane sponge, there is a cap made of energyized graphene sheets.

[0031] The water contact angle figure of the superhydrophobic graphene / polyur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com