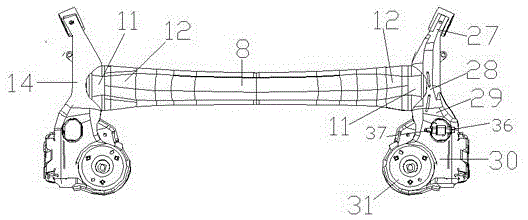

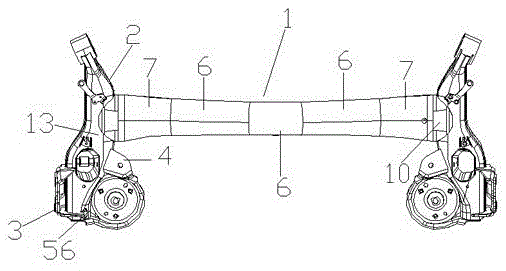

Rear-axle assembly with overlapping of torsion-beam main beam, upper-plate side beam and lower-plate side beam and manufacture method thereof

A side beam and torsion technology, applied in the field of vehicle parts manufacturing, can solve problems such as weak anti-rolling ability, mutual influence, and limited comfort, and reduce excessive local stress, small vertical positive and negative deviations, and complex processes The effect of reducing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

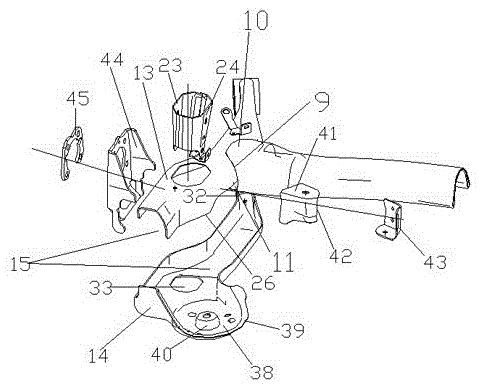

[0035] Below by embodiment, in conjunction with accompanying drawing, technical scheme of the present invention is described further in detail:

[0036] like Figure 1-6 As shown, a preparation method of a torsion beam main beam and a rear axle assembly with upper and lower plate side beams includes:

[0037] Step 1: Use hydroforming technology to make large-diameter sealed main girder round tubes with thin metal plates, and then use water-expansion forming and stretching to make U-shaped cross-section reinforced structural grooves at the bottom of the main girder of large-diameter sealed main girder tubes , make use of the large-diameter sealed main beam characteristics of the main beam itself to make side beam lap connection ports with a large cross-sectional perimeter at both ends of the nozzle and pipe tail;

[0038] Step 2: Use two unconnected metal plates to make the upper plate of the side beam and the lower plate of the side beam respectively. The forming shape is a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com