Automatic positioning and pressing device for vehicle parts

A technology for automatic positioning of auto parts, applied in the field of auto parts, can solve the problems of small movement, bulkiness, and bulky fixtures, etc., and achieve the effect of guaranteeing machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

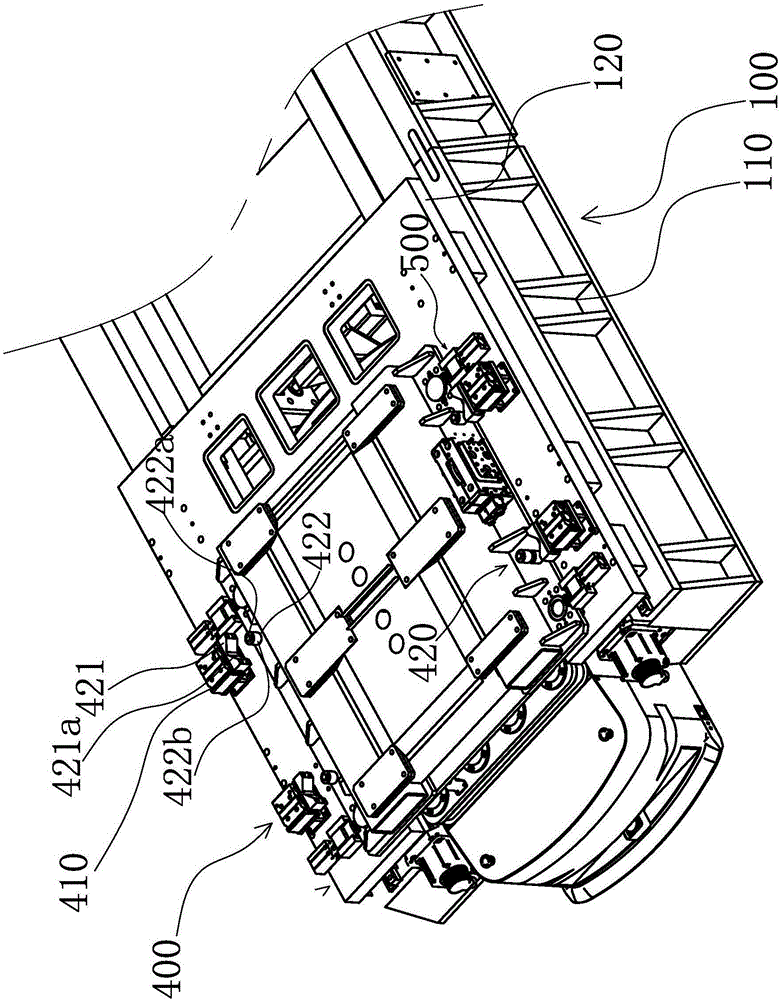

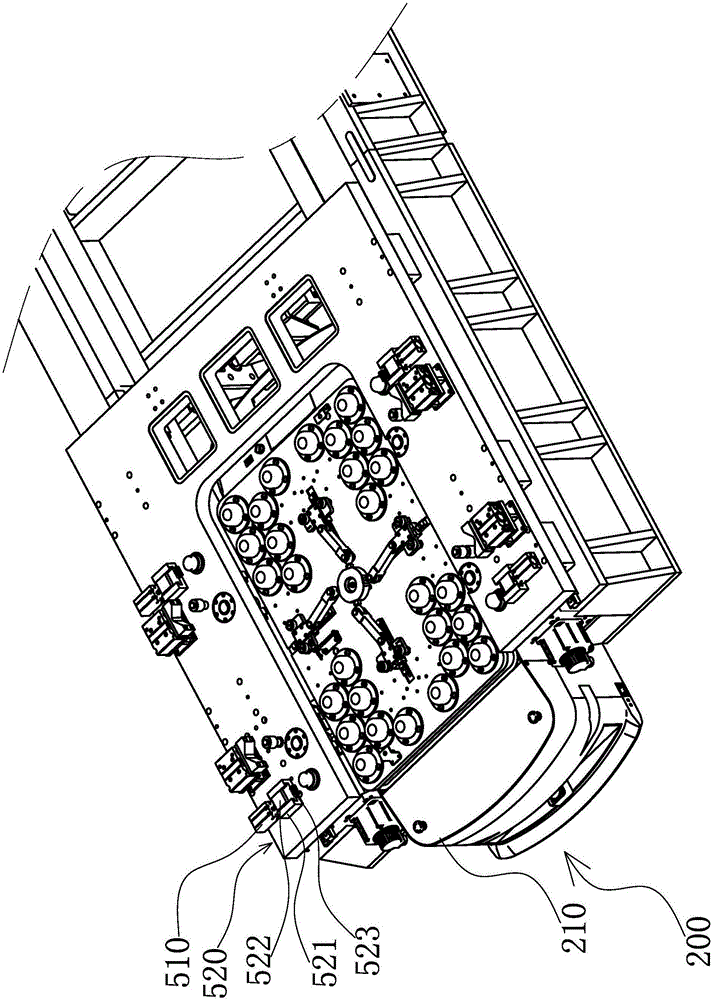

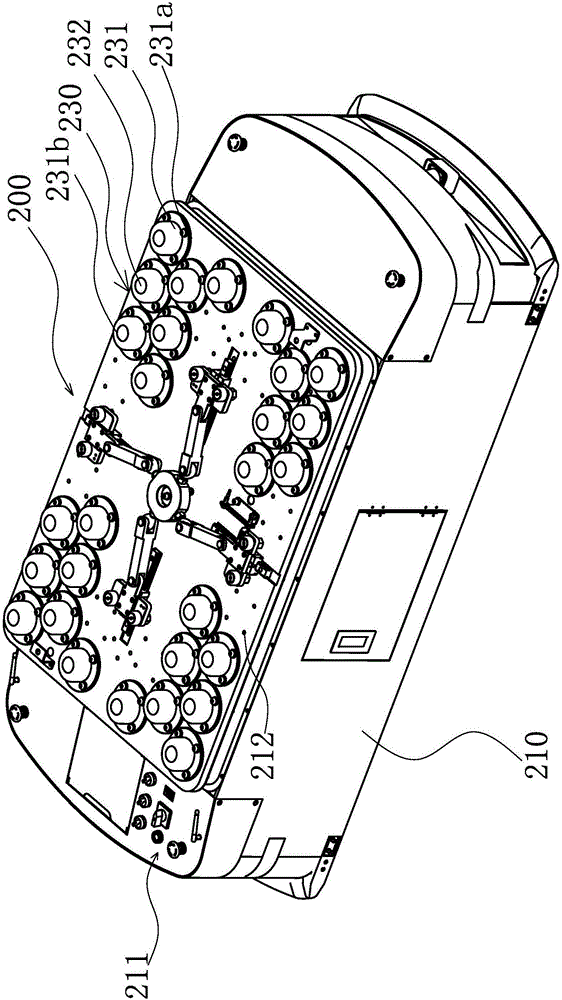

[0090] Such as figure 1 , figure 2 as well as Figure 6 As shown, an automatic positioning and pressing device for auto parts provided by the present invention includes: a bracket 100 including two guide rails 110 parallel to each other, and each guide rail 110 is provided with a base plate 120; an alignment mechanism 200 , located between the two guide rails 110 ; the lifting mechanism 300 is installed on the substrate 120 ; the positioning mechanism 400 is installed on the substrate 120 ; the pressing mechanism 500 is installed on the substrate 120 .

[0091] The working principle of an automatic positioning and pressing device for auto parts provided by the present invention: first, the required jig is transported fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com