High-frequency oscillating wave capacitance method oil leakage detection and alarm device

A leakage detection and high-frequency oscillation technology, which is applied in the field of oil leakage alarm, can solve the problems of increasing the workload of the staff, not being able to find it in time, and the astonishingly high price, so as to achieve safe and reliable detection results, improve detection accuracy, and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

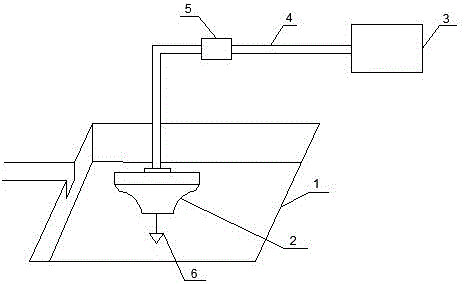

[0025] Such as Figure 1 to Figure 3 As shown, the present invention includes a water tank 1, a detector 2 and a converter 3. The water tank 1 is arranged at a low point in the tank area of the oil storage tank to ensure that the leaked oil and sundries can flow into the water tank 1, and the detector 2 is arranged on the water surface Above, the signal output end of the detector 2 is connected to the signal input end of the converter 3 through the cable 4. In this embodiment, the detector 2 and the converter 3 are connected through the junction box 5 through the cable 4, and the detector 2 The power supply end is connected to the power supply through the converter 3, the detector 2 is used to detect oil leakage, and is input to the converter 3 through the cable 4, and the converter 3 is used to process the signal detected by the detector 2 to judge whether oil leakage occurs .

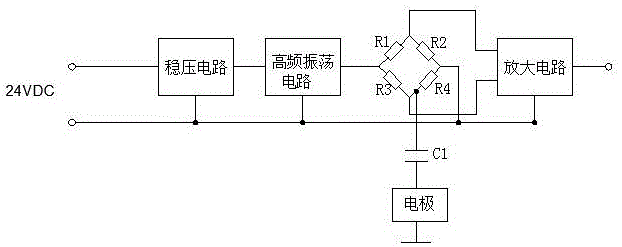

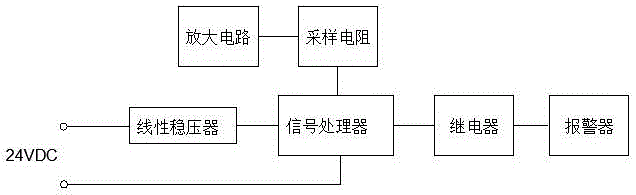

[0026] The detector 2 includes a casing and a detection circuit arranged in the casing. The det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com