Multilayer wear-resisting yoga mat

A technology for yoga mats and fiber cloth layers, applied in layered products, rubber layered products, synthetic resin layered products, etc., can solve the problems of poor surface wear resistance and low service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

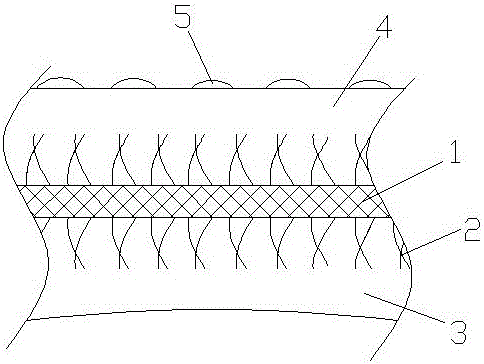

[0057] like figure 1 Shown, a kind of multi-layer wear-resistant yoga mat, this multi-layer wear-resistant yoga mat comprises the fiber cloth layer 1 densely covered with protruding fiber burrs 2 on the upper and lower surfaces, and the upper and lower surfaces of the fiber cloth layer 1 are respectively provided with polyurethane foam boards 4 and the rubber substrate 3, and the lower surface of the rubber substrate 3 is an arc-shaped surface concave from the edge to the middle, and the upper surface of the polyurethane foam board 4 is densely covered with arc-shaped protrusions 5 protruding from its surface 2-3mm.

[0058] The above is the basic implementation of this embodiment, further optimization, improvement and limitation can be done on the basis of the above:

[0059] For example, the fiber cloth layer 1 is a non-woven fabric made by a conventional needle-punched non-woven process after mixing PAN-based carbon fiber precursors, glass fiber filaments and polypropylene fi...

Embodiment 2

[0076] like figure 1 Shown, a kind of multi-layer wear-resistant yoga mat, this multi-layer wear-resistant yoga mat comprises the fiber cloth layer 1 densely covered with protruding fiber burrs 2 on the upper and lower surfaces, and the upper and lower surfaces of the fiber cloth layer 1 are respectively provided with polyurethane foam boards 4 and the rubber substrate 3, and the lower surface of the rubber substrate 3 is an arc-shaped surface concave from the edge to the middle, and the upper surface of the polyurethane foam board 4 is densely covered with arc-shaped protrusions 5 protruding from its surface 2-3mm.

[0077] The above is the basic implementation of this embodiment, further optimization, improvement and limitation can be done on the basis of the above:

[0078] For example, the fiber cloth layer 1 is a non-woven fabric made by a conventional needle-punched non-woven process after mixing PAN-based carbon fiber precursors, glass fiber filaments and polypropylene ...

Embodiment 3

[0095] like figure 1 Shown, a kind of multi-layer wear-resistant yoga mat, this multi-layer wear-resistant yoga mat comprises the fiber cloth layer 1 densely covered with protruding fiber burrs 2 on the upper and lower surfaces, and the upper and lower surfaces of the fiber cloth layer 1 are respectively provided with polyurethane foam boards 4 and the rubber substrate 3, and the lower surface of the rubber substrate 3 is an arc-shaped surface concave from the edge to the middle, and the upper surface of the polyurethane foam board 4 is densely covered with arc-shaped protrusions 5 protruding from its surface 2-3mm.

[0096] The above is the basic implementation of this embodiment, further optimization, improvement and limitation can be done on the basis of the above:

[0097] For example, the fiber cloth layer 1 is a non-woven fabric made by a conventional needle-punched non-woven process after mixing PAN-based carbon fiber precursors, glass fiber filaments and polypropylene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com