Combined grounding wire assembly

A grounding wire and combined technology, applied in the direction of connection, conductive connection, electrical component connection, etc., can solve problems such as laborious, increased safety risks of climbing operations, and small space in 10kV switch cabinets, so as to ensure the safety of equipment and personal safety , save recycling and sorting time, and avoid the effect of climbing operation risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with specific embodiments and accompanying drawings.

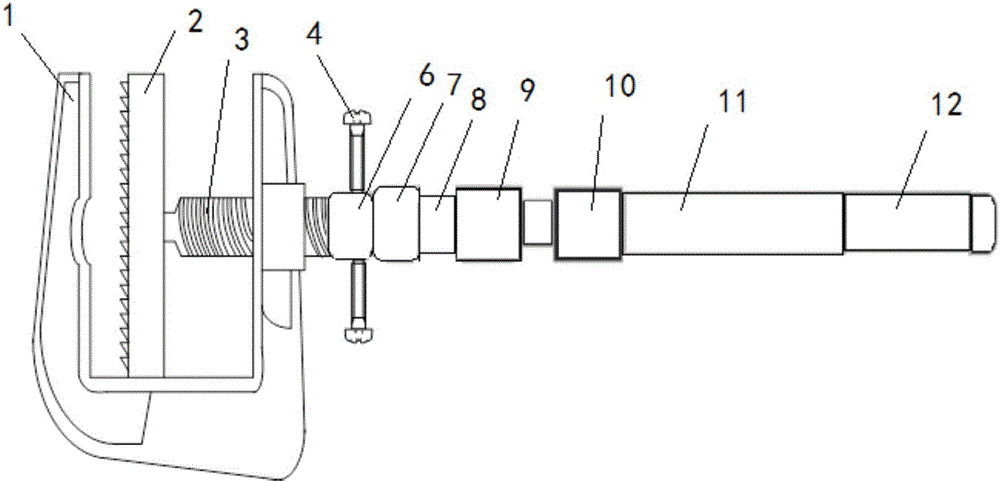

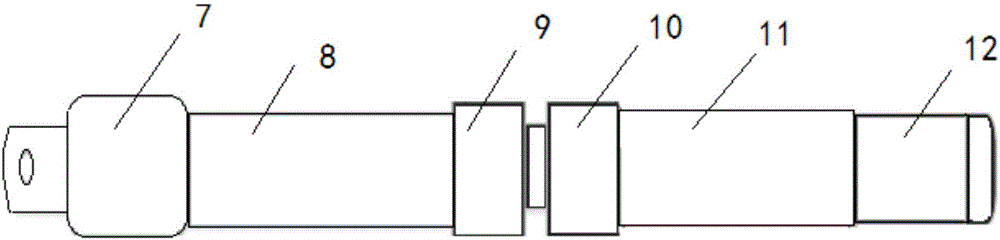

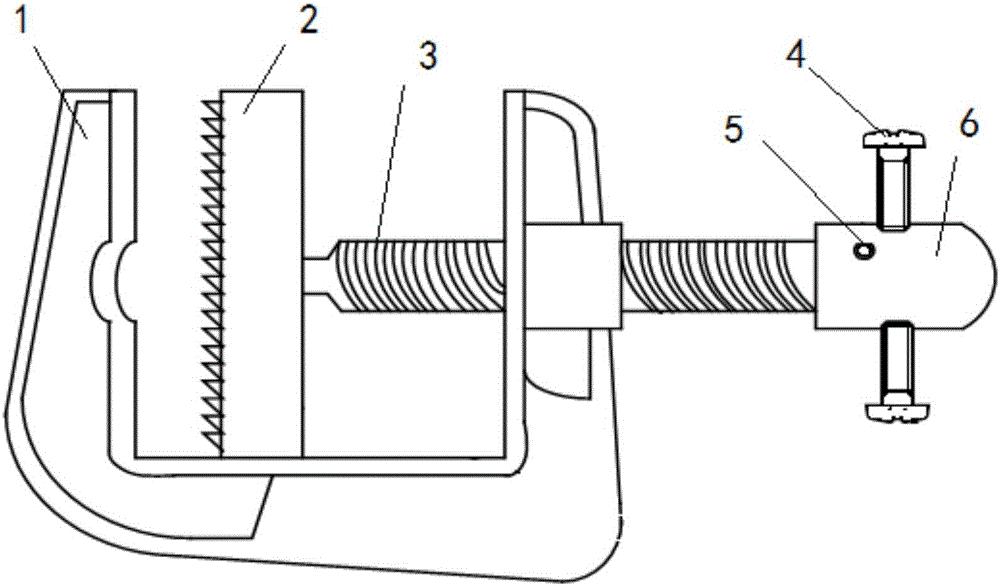

[0026] see figure 1 , the present invention includes the connecting clips and insulating rods connected in sequence, see image 3 , the wiring clip includes a U-shaped clamping mouth 1, the clamping part of the clamping mouth 1 is provided with a notch for clamping the line, the clamping mouth 1 is provided with a moving tongue 2, and the clamping part of the moving tongue 2 is provided with a Sawtooth structure, the moving tongue 2 is connected to one end of the screw 3, the screw 3 is threaded to the jaw 1, and the other end of the screw 3 is provided with a joint 6; see figure 2 , the insulating rod includes an insulating rod bayonet 7 connected to the joint 6, the insulating rod bayonet 7 is provided with a connecting piece, the joint 6 is provided with a slot for clamping the connecting piece, and the side walls of the joint 6 are located on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com