Link fitting and converter station with same

A technology for connecting metal fittings and fittings, applied in the field of converter stations, can solve problems such as large force on equipment terminals, and achieve the effect of ensuring service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

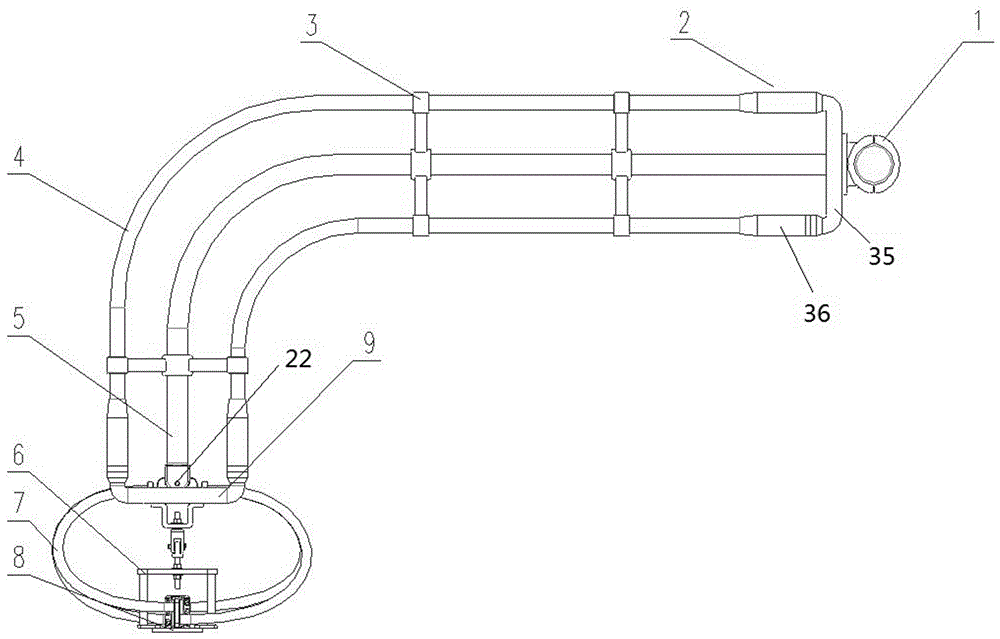

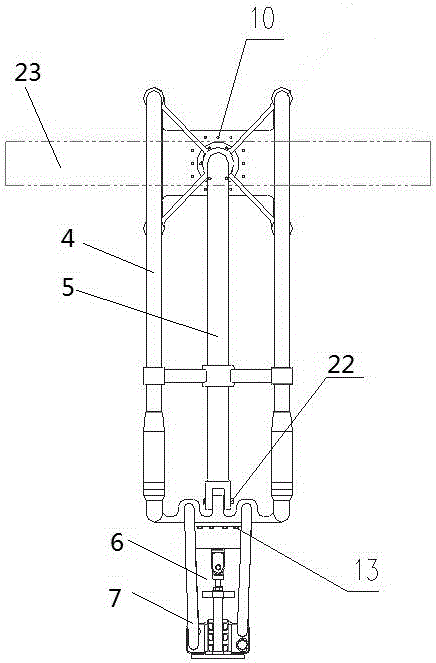

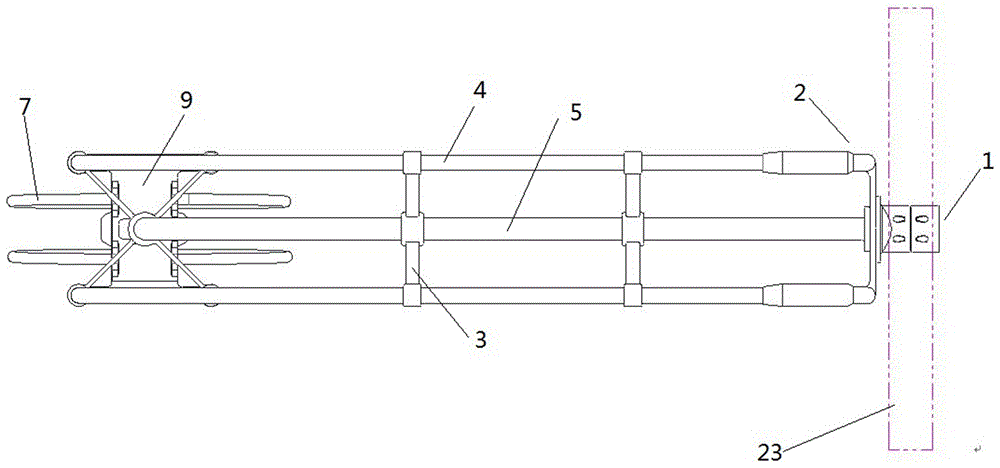

[0041] Embodiment 1 of the converter station is as Figure 1~8As shown: It includes a converter transformer and a capacitor. The equipment terminal of the converter transformer, that is, the outlet bushing on the grid side, is connected to the equipment terminal 23 of the capacitor through connecting fittings. The equipment terminal 23 of the capacitor is a tube mother structure. The connecting fittings include conductors and fitting supports arranged along the arrangement direction of the conductors. The conductors include four split wires 4 evenly distributed along the circumferential direction. The fitting supports include support rods 5 arranged between the split wires. The support rods 5 are aluminum alloy tubes , the split wire 4 is connected to the support rod 5 through the connecting structure. Both the split wire 4 and the hardware support are L-shaped structures with short sides and long sides, the short sides are vertically arranged, and the long sides are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com