Fuse protector and fuse protector base thereof

A fuse and fuse link technology, applied in electrical components, circuits, emergency protection devices, etc., can solve the problems of dimensional deviation, defective products, and high rework rate, and achieve the effect of reducing processing accuracy and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

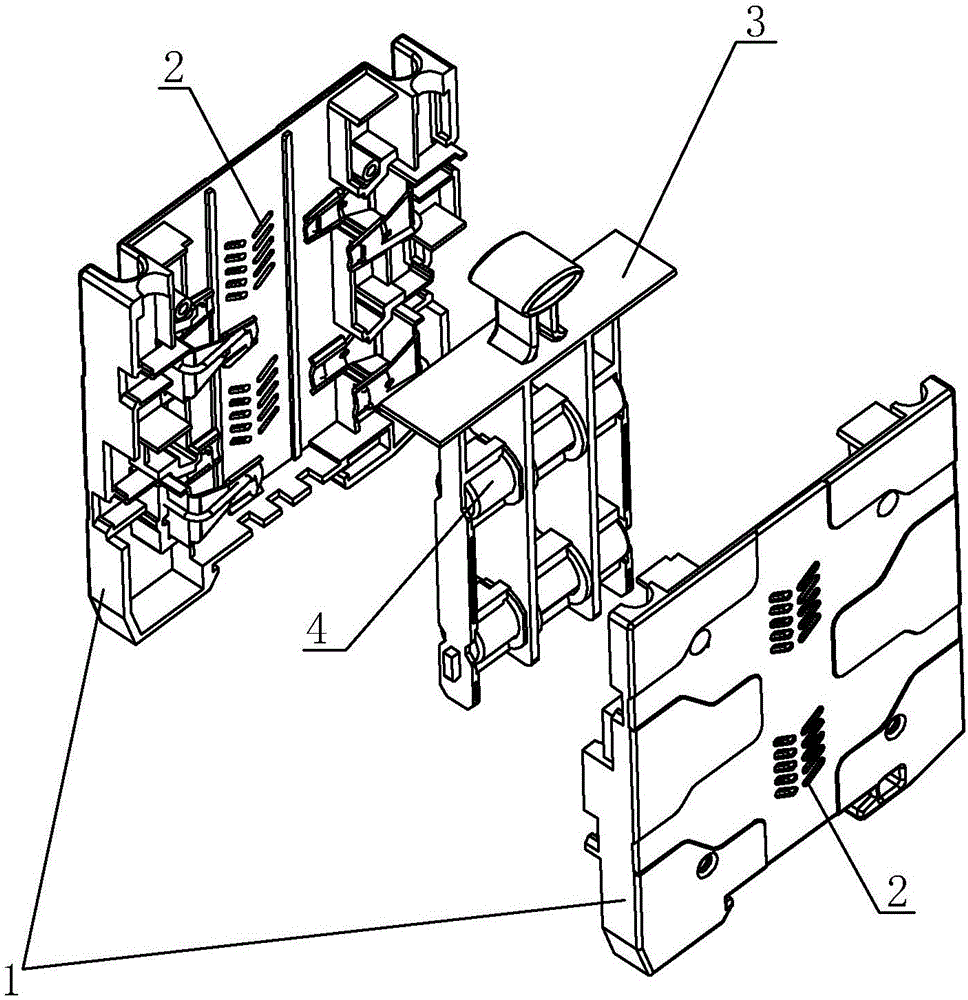

[0035] This embodiment discloses a fuse, such as figure 1 As shown, this embodiment is composed of a fuse base and a fuse body 4 installed in the fuse base. The fuse body 3 is composed of; the fuse body 4 is installed on the melt body 3; the positions corresponding to the fuse body 4 on the left housing and the right housing are provided with cooling holes 2.

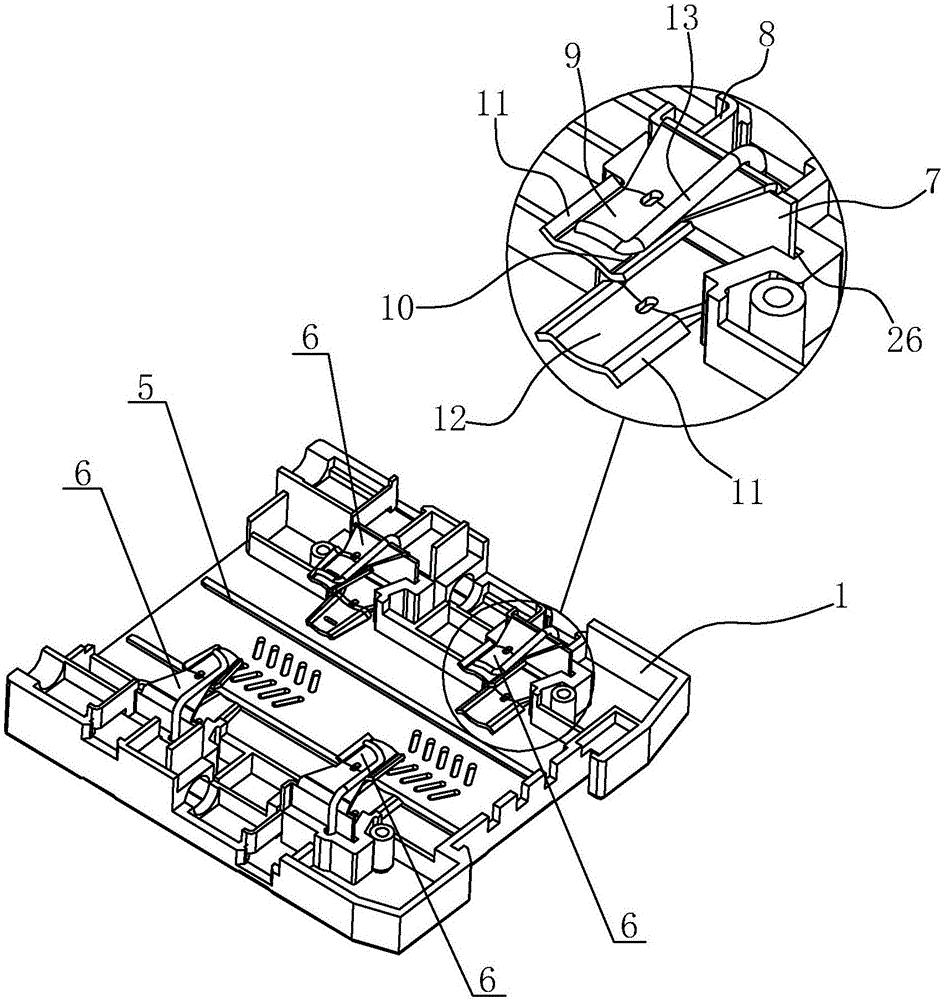

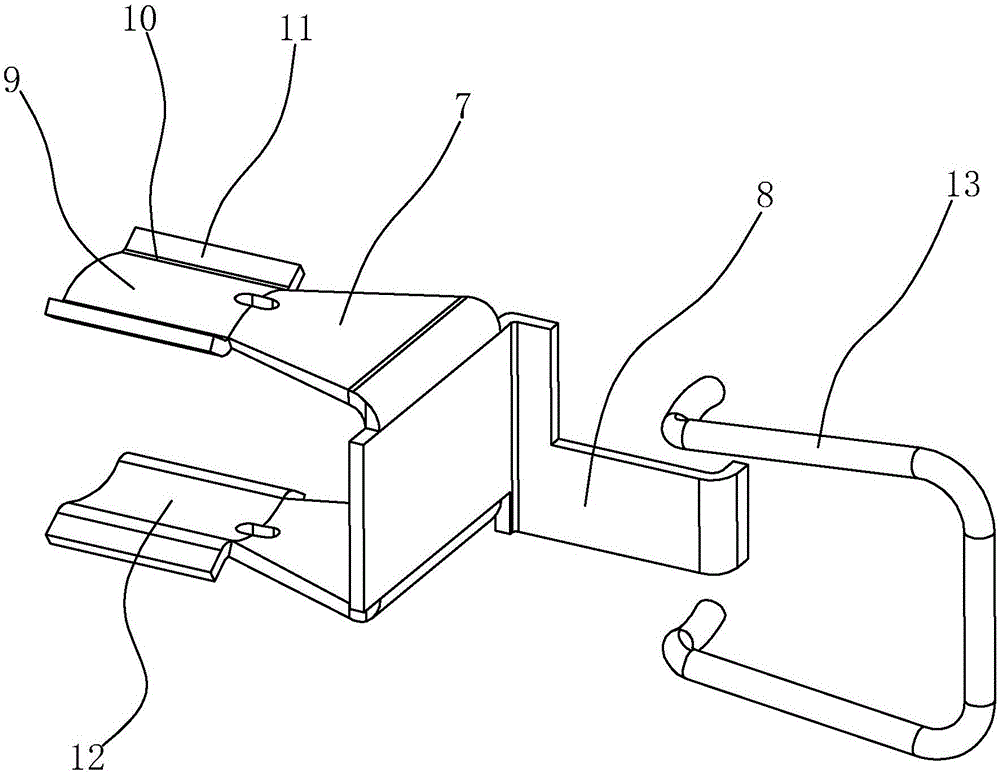

[0036] Such as figure 1 , 2 As shown, the casing 1 is provided with a chute 5 for the sliding of the melt 3 , one side of the chute 5 is distributed with two base contacts 6 along the chute 5 , and the other side of the chute 5 is also provided with two A base contact 6, the base contact 6 on both sides of the chute 5 is relatively arranged; combined figure 2 , image 3As shown, the base contact 6 includes a curved U-shaped elastic clip 7 and a terminal board 8 integrally connected with the elast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com