Fixing structure for outdoor small spacing LED (Light Emitting Diode) display screen module mask

A technology of LED display screen and fixed structure, which is applied in the direction of casing/cabinet/drawer parts, instruments, identification devices, etc., which can solve the problems of small space and difficulty in installing and fixing the mask, achieve good bearing capacity and solve the problem of fixing Problems, the effect of firm installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

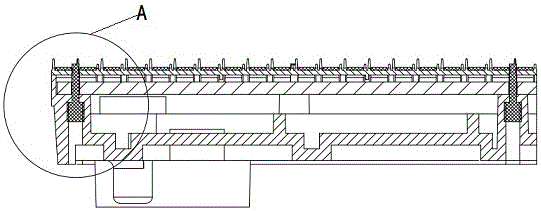

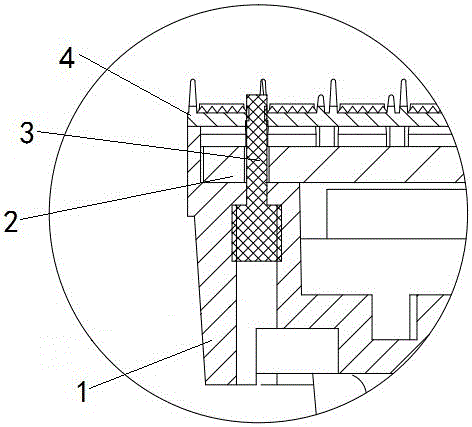

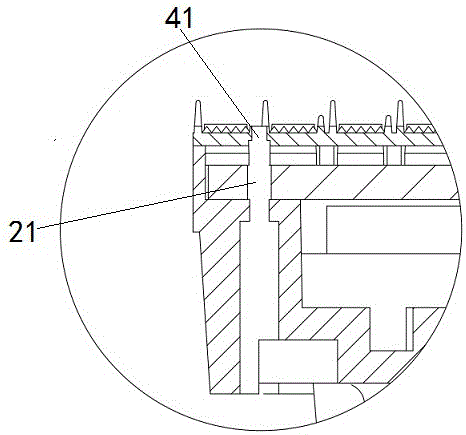

[0025] refer to Figure 1~6 , the fixing structure of an outdoor small-pitch LED display module mask provided by the present invention includes a bottom shell 1, an LED panel 2 fixed on the bottom shell 1, a mask 4 fastened to the LED panel 2 and a face shield for fixing the mask. 4 multiple cylinders 3 . The cylinder 3 is a stepped cylinder, including a first step 31 and a second step 32, the diameter of the first step 31 is greater than the diameter of the second step 32, wherein the first step 31 is a straight-toothed cylinder, and the end of the second step 32 is straight Tooth cylinder. Wherein, the first step of the cylinder 3 is integrally formed with the bottom case 1 through injection molding. The LED panel 2 is provided with a through hole 21 corresponding to the cylinder 3, and the mask 4 is provided with a mounting hole 41 corresponding to the cylinder 3, and a small cylinder 42 is provided on the back thereof, and the small cylinder 42 is injected together with ...

Embodiment 2

[0028] refer to Figure 7 When the mask 4 is installed, a glue bonding layer is pre-set on the back, and then the mounting hole 41 of the mask 4 corresponds to the second step 32 of the cylinder, and the end of the second step 32 is squeezed into the mounting hole 41, and the process is completed. Installation of mask 4. The rest of the parts are the same as those in Embodiment 1, and will not be repeated again.

[0029] Due to the interference fit between the second step 32 and the mounting hole 41 of the mask 4 and the effect of glue, the installation of the mask 4 is more firm. The column body 3 of the stepped structure not only ensures better bearing capacity, but also effectively solves the problem of small fixing space for the small-pitch LED display screen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com