Multi-station automatic detection integrated equipment

An automatic detection and multi-station technology, applied in the field of electrical detection, can solve the problems of low efficiency, time-consuming and labor-intensive, etc., and achieve the effect of preventing hidden accidents, improving detection efficiency, and avoiding messy gas pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

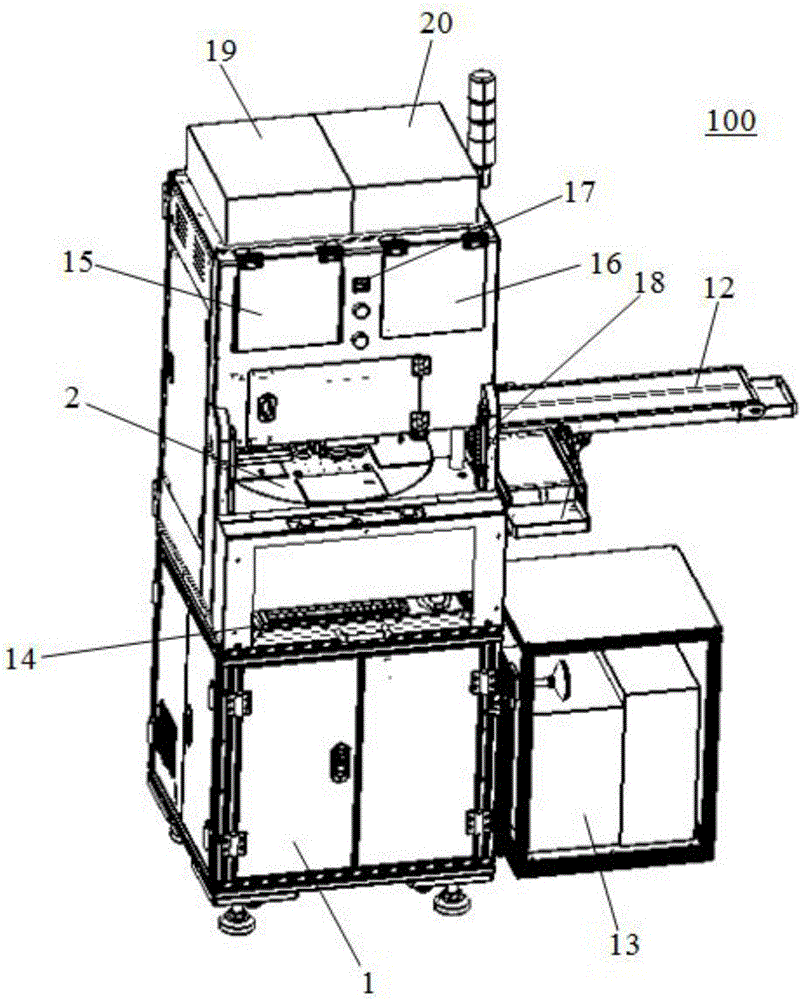

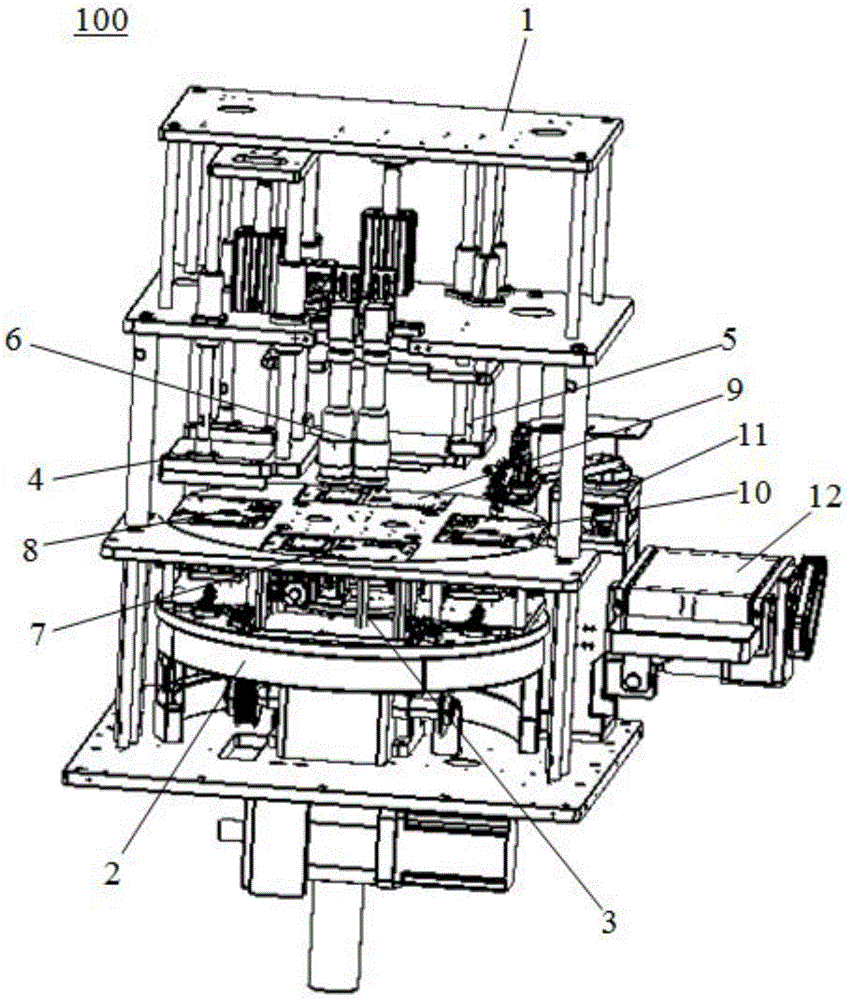

[0033] Please refer to Figure 1-Figure 8 , the present embodiment is a multi-station automatic detection integrated equipment 100, which includes a cabinet 1, a rotary conveying module 2 fixed on the cabinet 1, a number of lower handles fixed on the rotary conveying module 2 and rotating with it. The tool device 3, the loading station 7, the first inspection station 8, the second inspection station 9 and the unloading station 10 arranged around the rotary conveying module 2. On the cabinet 1, a first pressing detection device 4 is fixed above the first detection station 8, a second pressing detection device 5 is fixed above the second detection station 9, and a CCD position acquisition device 6. On the cabinet 1, a blanking module 11 is arranged beside the blanking station 10, and a blanking conveying module 12 is arranged beside the blanking module 11.

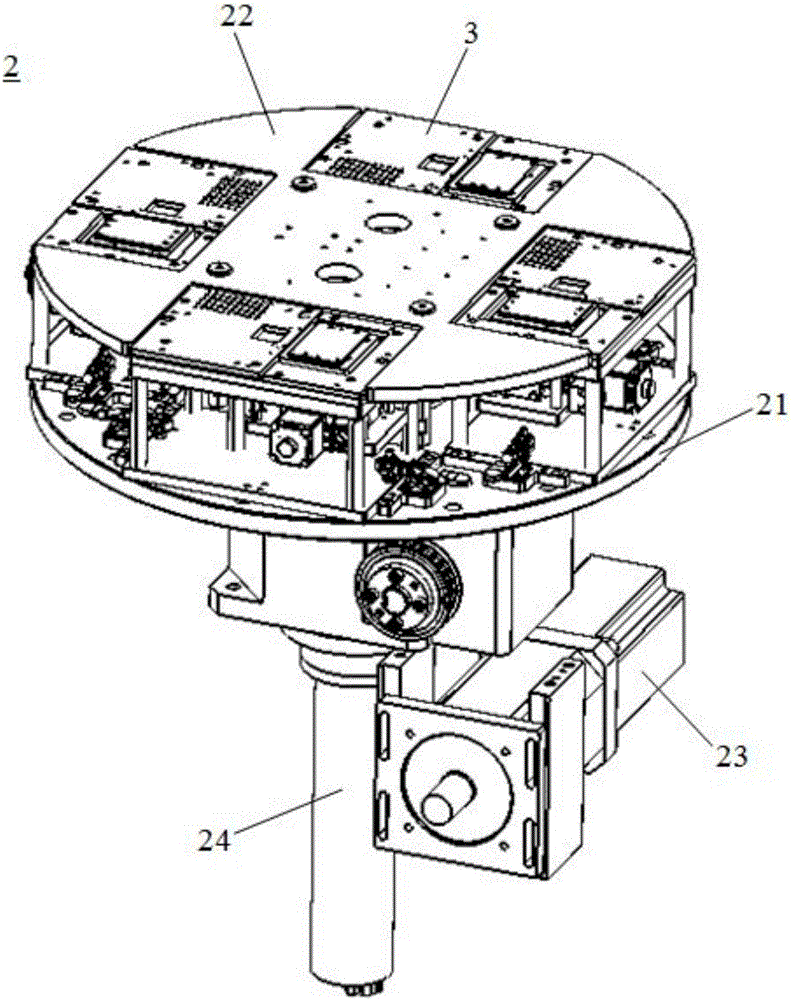

[0034] The rotary conveying module 2 is a quarter-disk structure, which includes a first mounting surface 21, a second m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com