Field-eddy thermal imaging detection system and method for surface defect of steel product/billet

A detection system and thermal imaging technology, applied in the direction of material defect testing, material magnetic variables, etc., can solve the problems of uneven heating of the inspected object, inability to realize steel/billet continuous, dynamic, high-speed, accurate detection, and low detection accuracy , to achieve the effect of automatic marking, avoiding uneven heating and environmental temperature influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

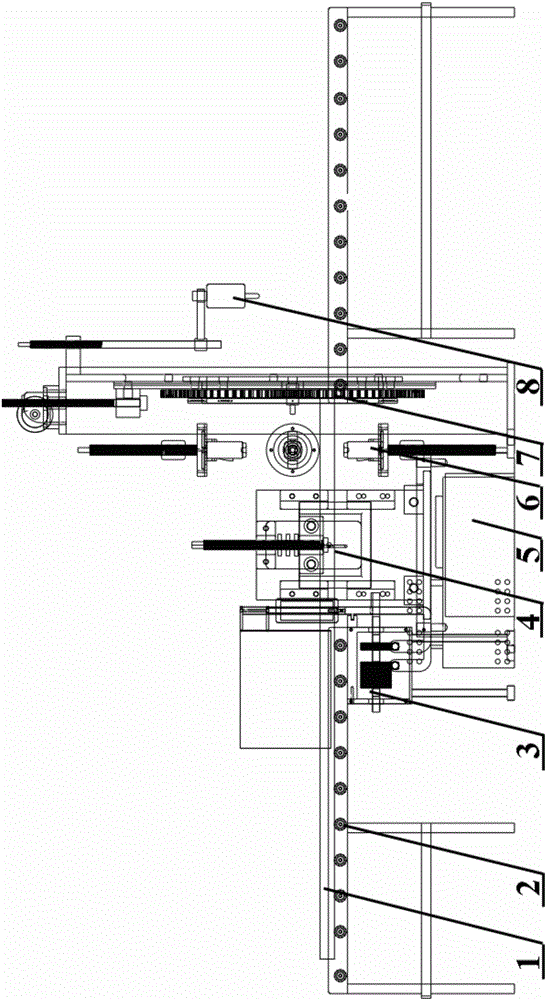

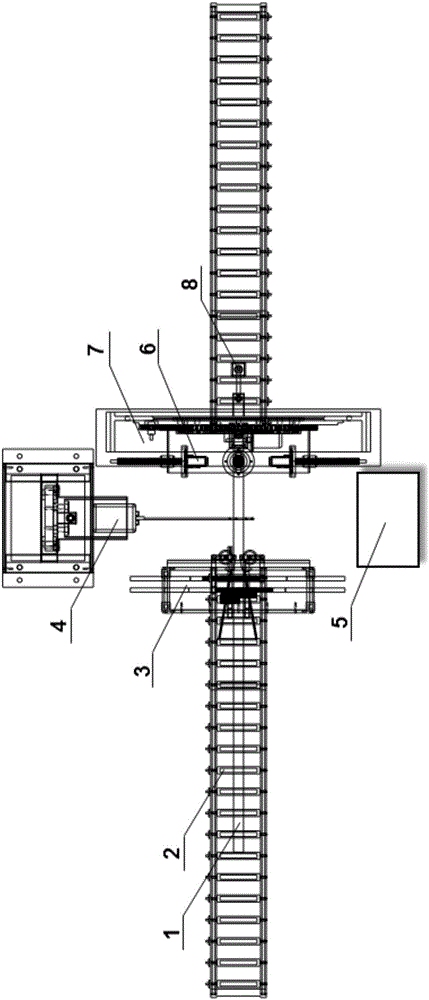

[0069] Select the Q345 rectangular pipe for construction as the object to be inspected, and its cross-section is 125mm×125mm. First adjust the distance between the left wheel 31a and the right wheel 31b between 125mm-125.2mm; then adjust the distance from the lens of the infrared thermal imager 6 to the surface of the square tube to be 600mm; then adjust the position of the high-frequency induction heating device 4, select as Figure 5 The induction heating coil shown ensures that the center of the cross-section of the rectangular tube coincides with the center of the coil, the coil lift is between 5mm-10mm, and the lateral distance between the coil and the lens of the infrared thermal imaging camera 6 is within 5cm. At the same time, turn on the switch of the feeding frame, high-frequency induction heating equipment and infrared thermal imager, set the conveying speed of the feeding frame to 6m / min, and heat the surface temperature of the square tube to 160°C-180°C instantane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com