A rapid detection method for plate damage

A detection method and fast technology, applied in vibration testing, measuring devices, testing of machine/structural components, etc., can solve problems such as missed detection and false alarm, and achieve the effect of speeding up detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

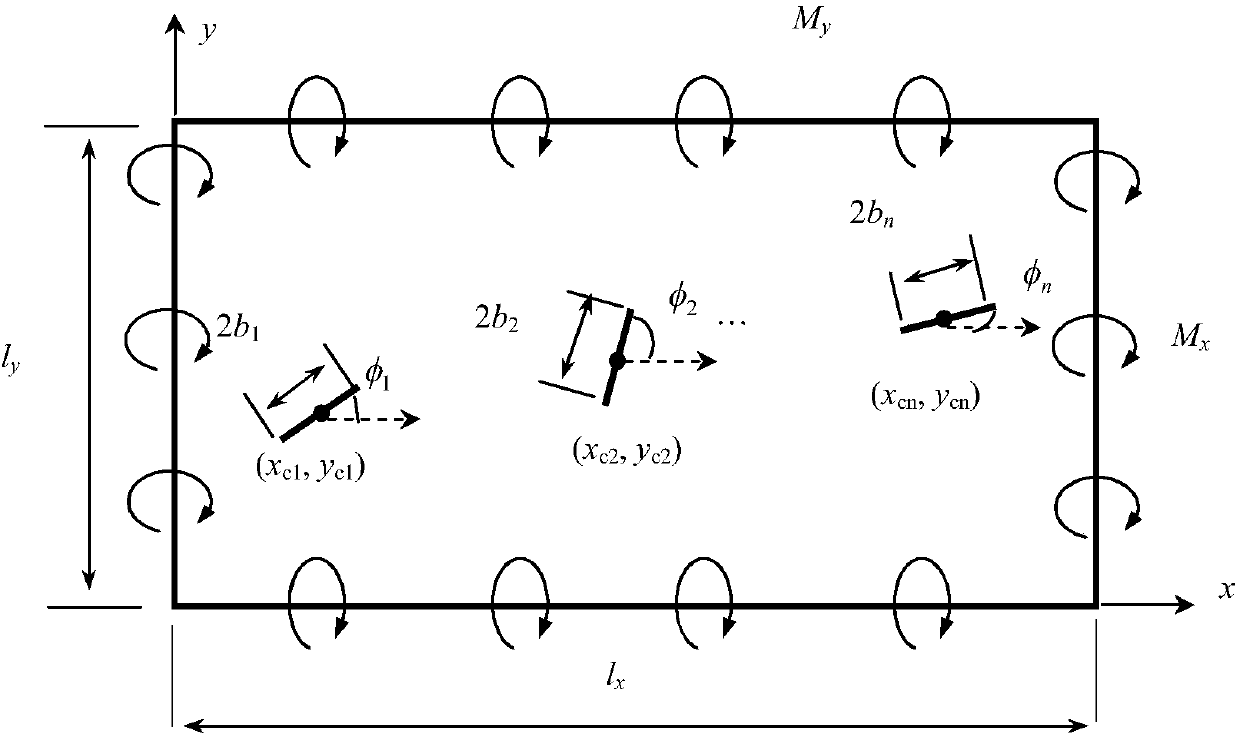

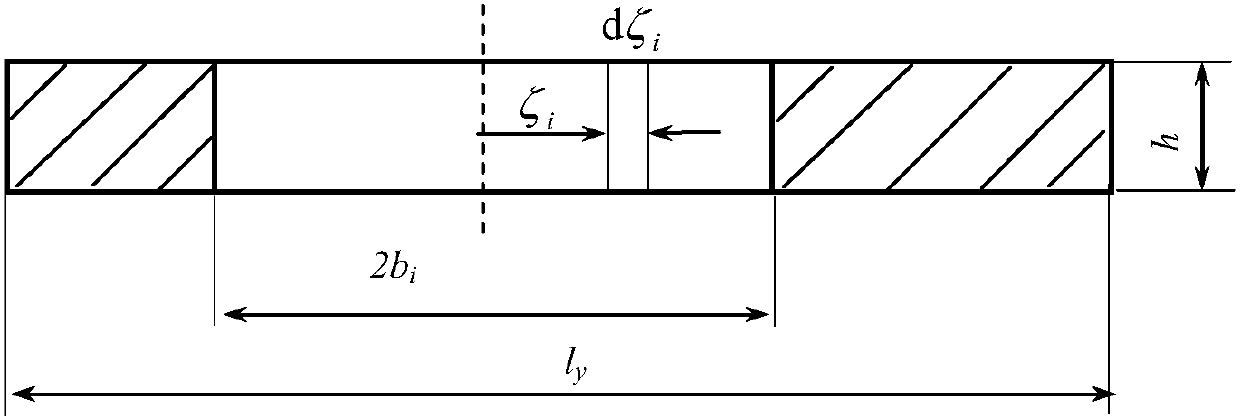

[0089] Implementation case 1: In order to verify the effectiveness of the natural frequency estimation formula (6) of the permeable damage thin plate structure in the method of the present invention for single damage, this implementation case is a permeable single damage four-sided simply supported thin plate structure, calculation parameters: l x = 150mm, l y =100mm, h=5mm, E=1.923×10 11 N / m 2 , μ=0.33, ρ=7810kg / m 3 . Figure 6 According to different relative damage center positions α c1 =x c1 / l x , β c1 =y c1 / l y , damage orientation relative lesion length γ 1 , eight damage cases are given.

[0090] Figure 7 Shown are the natural frequency estimation and finite element calculation solution results Compare. right Figure 6 Given eight working conditions, the maximum errors of the sixth order natural frequency are 0.146%, 0.293%, 0.063%, 0.121%, 0.079%, 0.036%, respectively. It can be seen that the results are in good agreement, indicating the effective...

Embodiment example 2

[0091] Implementation case 2: In order to verify the effectiveness of the natural frequency estimation formula (6) of the permeable damaged thin-plate structure in the method of the present invention to multiple damages, this implementation case is a permeable three-damaged four-sided simply supported thin-plate structure, and the calculation parameters are: l x = 150mm, l y =100mm, h=5mm, E=1.923×10 11 N / m 2 , μ=0.33, ρ=7810kg / m3 . Figure 8 According to different relative damage center positions α ci =x ci / l x , β ci =y ci / l y , damage orientation relative lesion length γ i , five damage cases are given.

[0092] Figure 9 Shown are the natural frequency estimation and finite element calculation solution results Compare. right Figure 8 Given the five working conditions, the maximum errors of the sixth-order natural frequency are 0.105%, 0.316%, 0.428%, 0.262%, 0.079%, and 0.038%, respectively. It can be seen that the results are in good agreement, indic...

Embodiment example 3

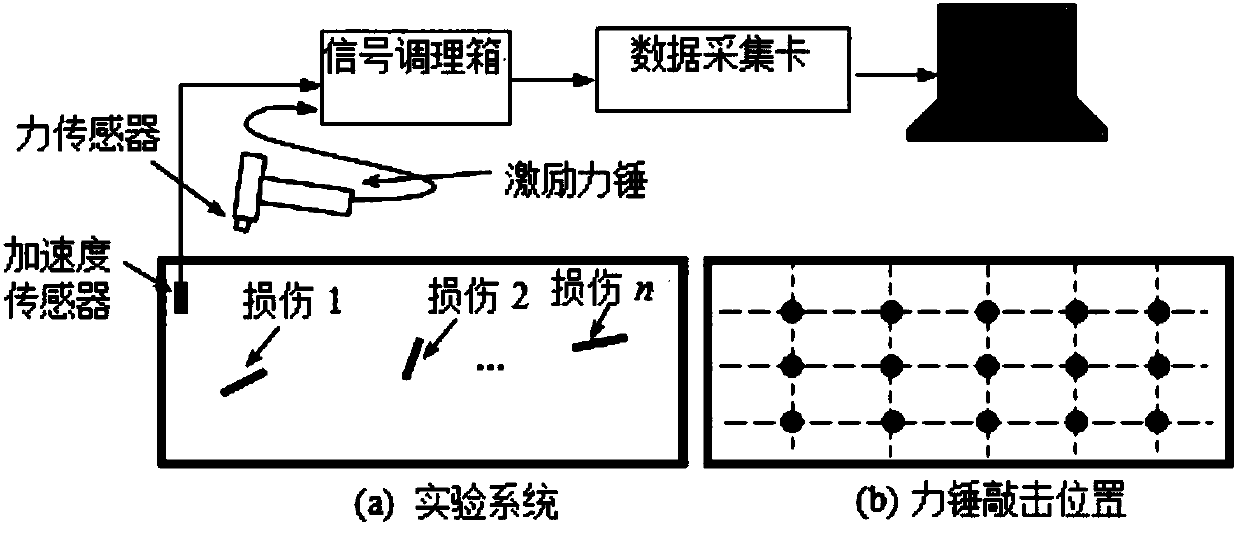

[0093] Implementation case 3: In order to verify the effectiveness of the detection method of the present invention, this implementation case detects the actual existence of two transparent damaged thin plate structures. Such as Figure 4 As shown, the geometric parameters are as follows: l x =1000mm, l y =1000mm, h=20mm, E=2.06×10 11 N / m 2 , μ=0.3, ρ=7860kg / m 3 . There are two damages on the thin plate structure: the position of the damage center (x c1 =0.1,y c1 =0.1) and (x c2 =0.6,y c2 =0.7), damage location and Lesion Relative Length γ 1 = 0.1 and γ 2 = 0.2.

[0094] Hammer-excited modal experiments such as image 3 As shown, for the actual two transparent damage thin plate structures, the sampling frequency f s = 4000Hz, the number of sampling points is 10000, and the first mode shape and the first three natural frequencies of the actual transparent damaged thin plate structure are obtained by using the hammer excitation mode experiment. The experimental...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com