Ultrasonic mass flowmeter

A mass flowmeter and ultrasonic technology, which is applied in the field of flowmeters, can solve the problem that mass flowmeters cannot be widely used in measurement sites, and achieve the effects of high measurement accuracy and simplified instrument structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further elaborated below with reference to the accompanying drawings.

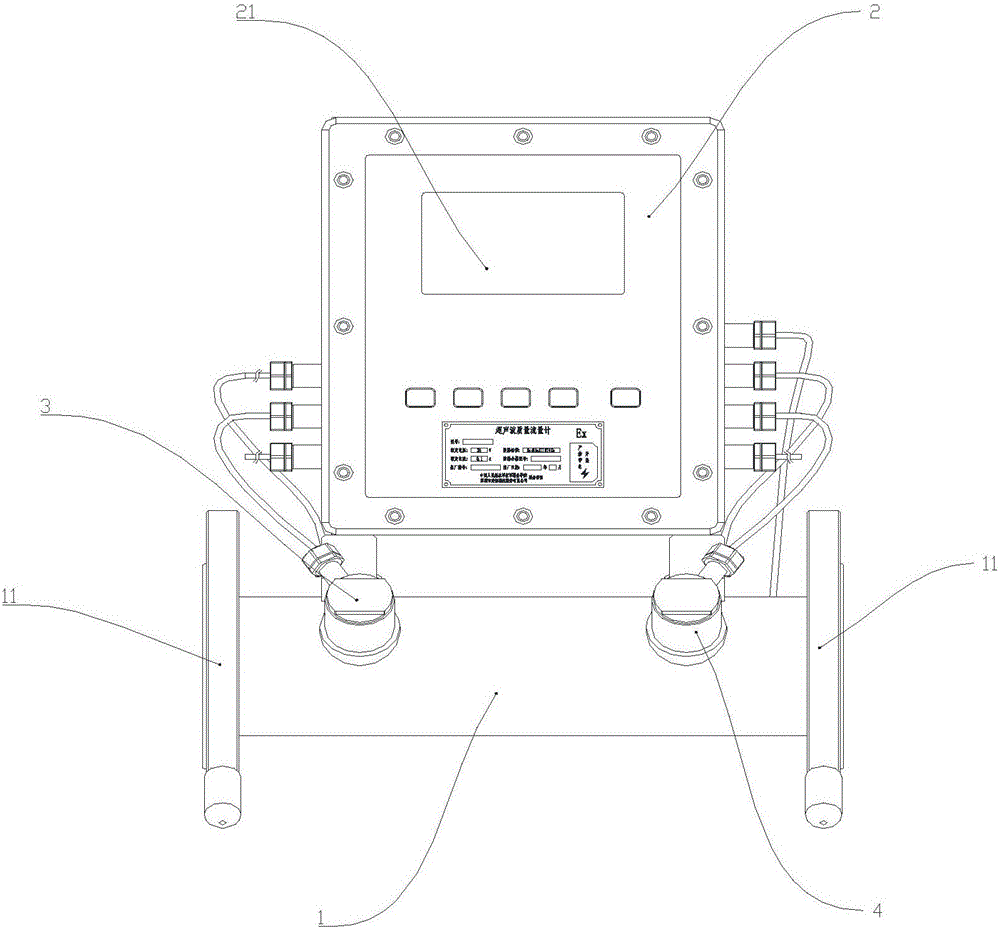

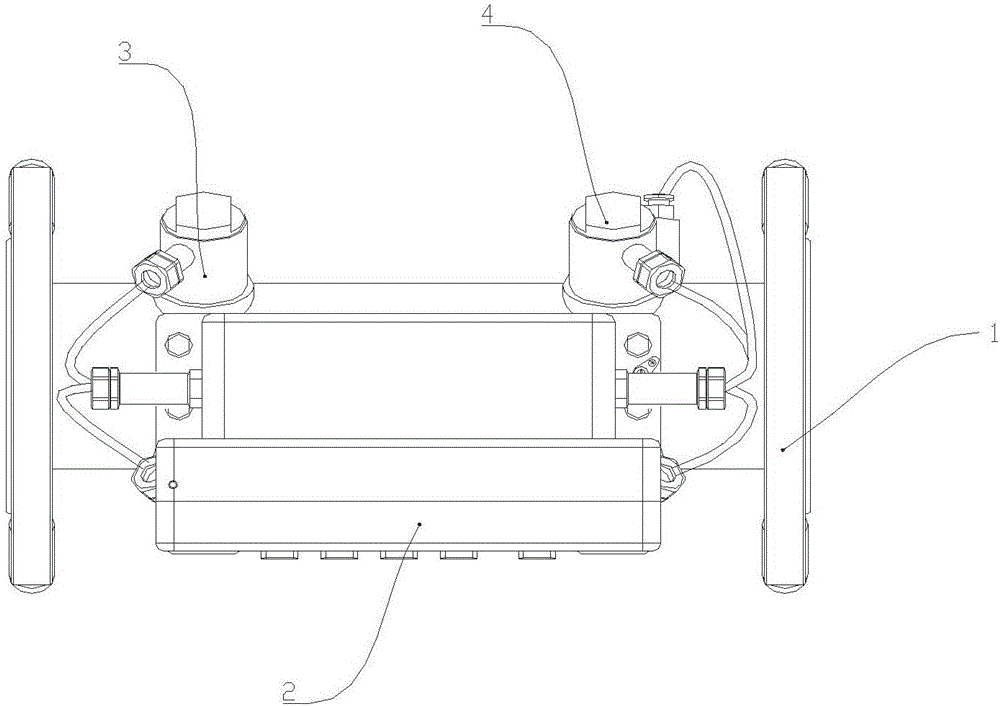

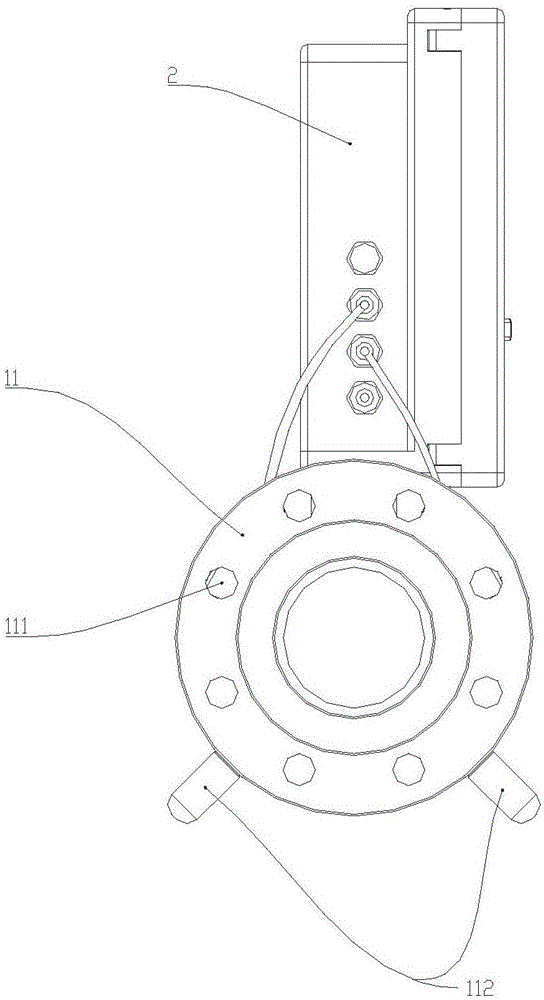

[0019] Please refer to the attached figure 1 to attach Figure 4 , in this embodiment, the ultrasonic mass flowmeter includes: a pipeline 1 for fluid to pass through, at least one set of ultrasonic sensors 3 arranged on the pipeline 1, and a measurement host 2; wherein, the measurement The host computer 2 controls the ultrasonic sensor 3 to transmit and receive signals, so as to obtain the mass flow value.

[0020] Wherein, the ultrasonic sensor 3 includes: an ultrasonic transmitter and an ultrasonic receiver, wherein the ultrasonic transmitter and the ultrasonic receiver are arranged on the upper and lower sides of the pipeline 1 respectively, and are located in the same plane passing the axis of the pipeline.

[0021] In this embodiment, the ultrasonic sensors 3 are divided into two groups, and the two groups of ultrasonic sensors are arranged on different surfaces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com