Optical filter wedge angle testing tool and optical filter wedge angle testing method

A technology for detecting tooling and optical filters, applied to measuring devices, instruments, etc., to achieve rapid measurement and avoid repeated image finding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

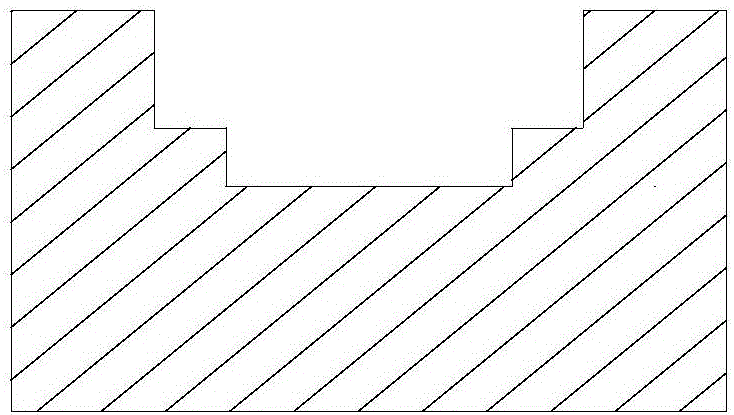

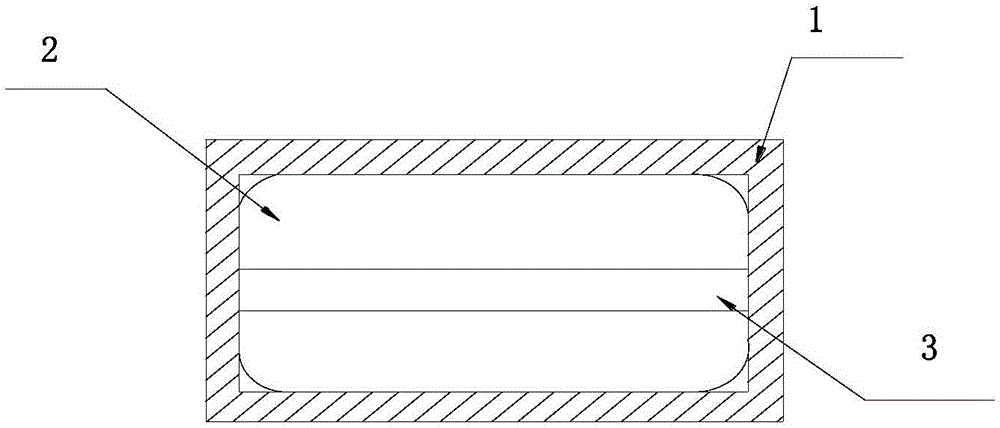

[0018] This embodiment proposes a tool for detecting the wedge angle of an optical filter, and the tool includes a guide rail and a stage. The section of the guide rail has a stepped structure, such as figure 1 shown. The stage is placed on the stepped structure of the guide rail and can slide along the guide rail. The stage includes a base 1 and a support 2, such as figure 2 As shown, the base 1 is in contact with the guide rail, the support 2 is embedded in the groove on the upper surface of the base 1 , and the upper surface of the support 2 has a positioning groove 3 for fixing the filter. Wherein, both the guide rail and the base are made of metal material, and the supporting part is made of glass material.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com