Ultrasonic method for determining layer depth of defects in laminar structure of composite

A composite material layer and composite material technology, applied in the field of non-destructive testing, can solve the problems of lack of quantitative characterization, insufficient depth quantification of detected defects, affecting judgment, etc., so as to improve the accuracy of judgment and measurement, improve the safety utilization rate and Yield, improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

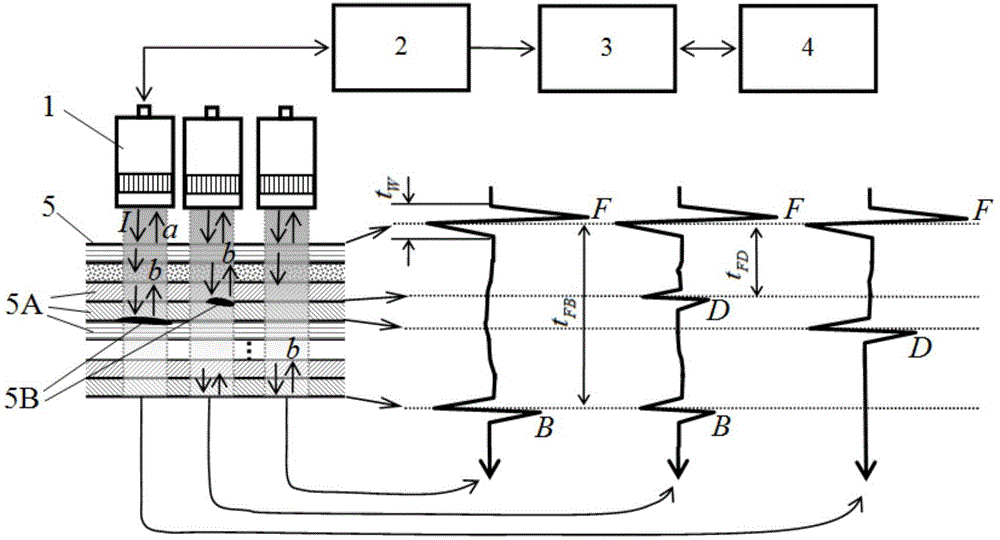

[0070] Choose UPowr-1, MUT-1 ultrasonic testing equipment and FJ-1 high-resolution transducer, CUS-6000, CUS-21J produced by AVIC Composite Materials Co., Ltd., and use water film coupling and liquid film coupling respectively to test various A series of practical detection applications have been carried out on the composite laminated structure, in which the frequency of the ultrasonic transducer is 5MHz, 10MHz and 15MHz, and the carbon fiber composite laminated structure is composed of 40 layers, h i ≈0.125mm, H≈40×0.125mm≈5mm, the delamination defect is located between the layers (5A) interface in the laminated structure (5) of the tested composite material, and the layer depth of the layer defect is n D The design values are 1 ply, 19 plies, and 39 plies respectively, and the equivalent size of delamination defects is Ф6mm. Ultrasonic testing:

[0071] In the defect-free region, t FB ≈3.24μs,

[0072] t corresponding to a stratification of 1 ply depth FD1 ≈0.08μs, obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com