Thermal/power combined drive steam jet type refrigeration device and refrigeration method thereof

A refrigeration device and jet-type technology, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of low efficiency, low refrigerant vapor flow rate, inelastic collision loss, etc., and achieve reduction of irreversible losses and high efficiency , reduce the effect of single dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

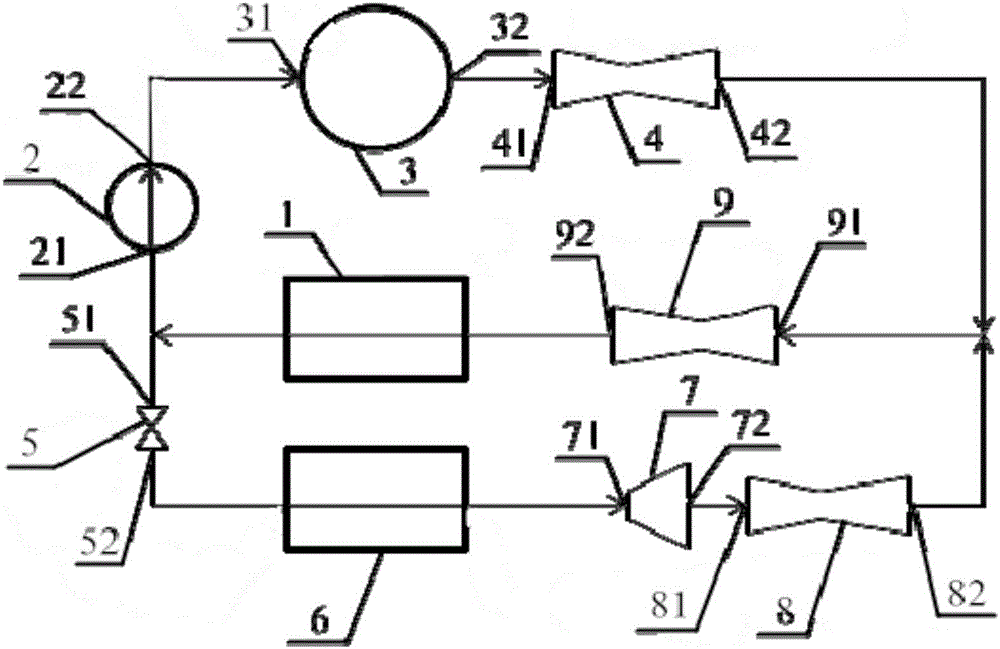

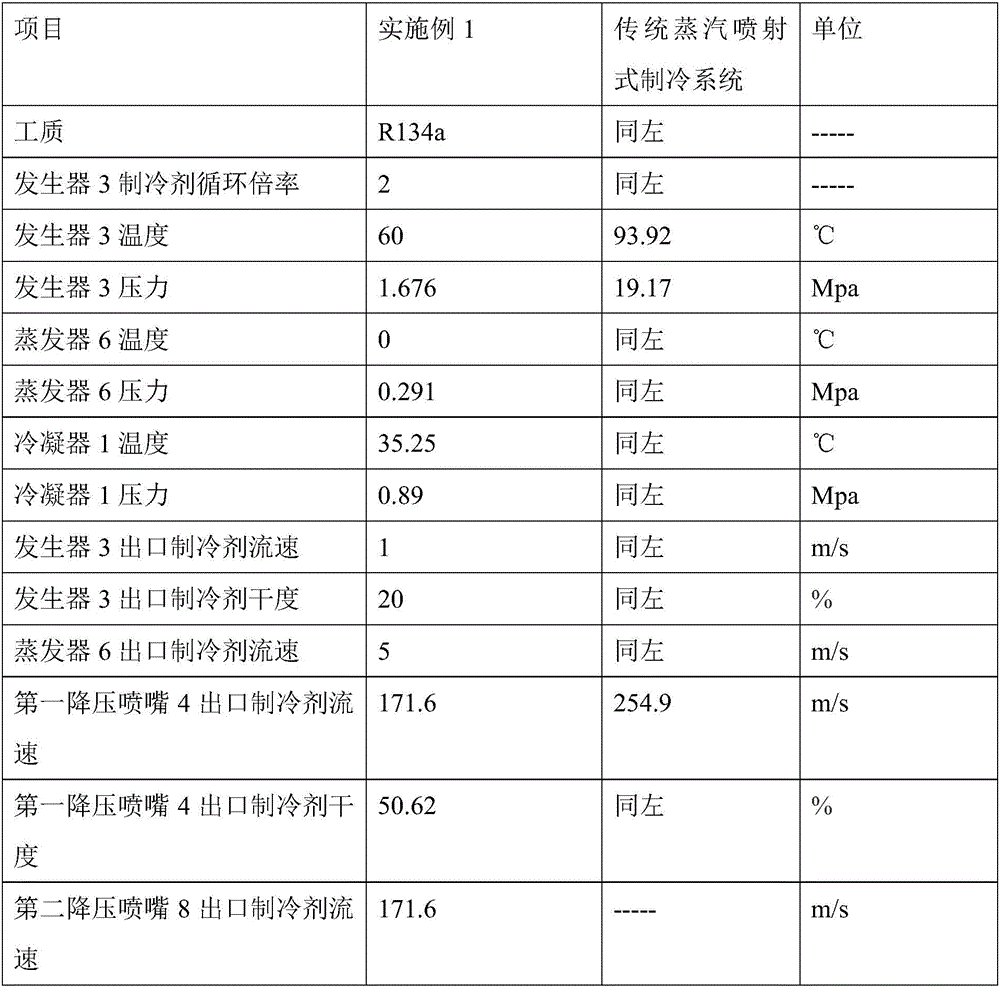

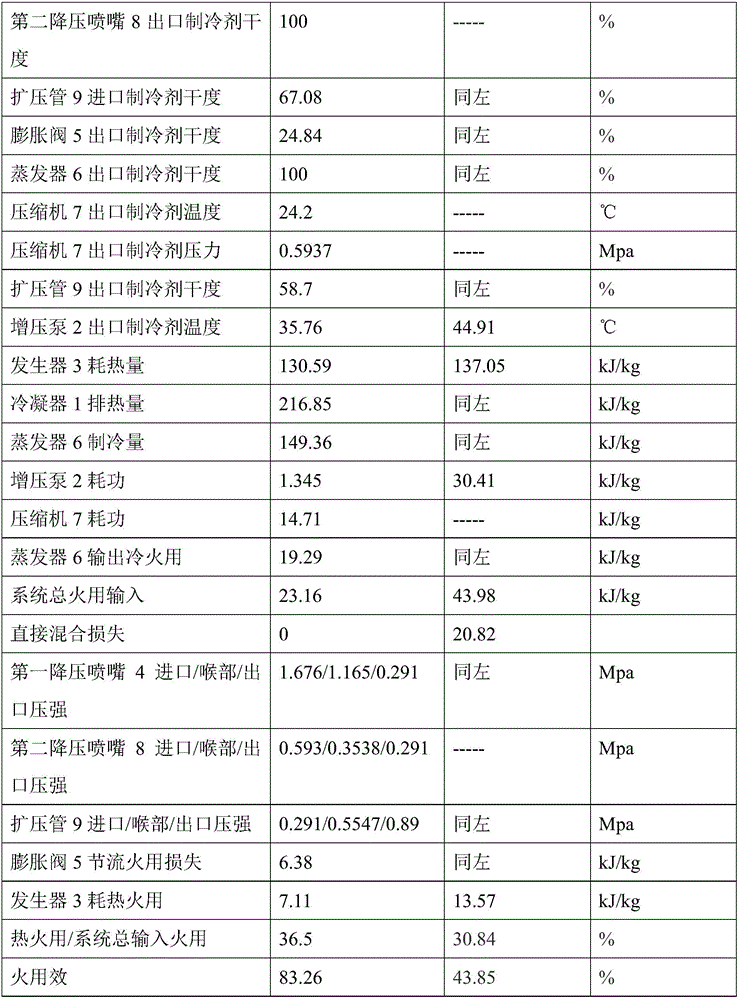

[0024] Embodiment 1, heat / power combined drive steam jet refrigeration device and refrigeration method thereof, such as figure 1 As shown, it includes a booster pump 2 , a generator 3 , a first decompression nozzle 4 , a diffuser 9 , a condenser 1 , an expansion valve 5 , an evaporator 6 , a compressor 7 and a second decompression nozzle 8 . The condensing pipeline of the condenser 1 is respectively connected with the booster pump refrigerant inlet 21 of the booster pump 2 and the expansion valve refrigerant inlet 51 of the expansion valve 5 through pipelines, and the booster pump refrigerant outlet 22 of the booster pump 2 is connected with the The generator refrigerant inlet 31 of the generator 3 is connected, and the booster pump 2 boosts the liquid refrigerant at ambient temperature passing therethrough to the pressure in the generator 3 . The generator refrigerant outlet 32 of the generator 3 is connected to the first pressure-reducing nozzle refrigerant inlet 41 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com