Air charging and releasing valve

A technology of air release valve and valve body, which is applied in the direction of valve details, valve device, valve shell structure, etc., which can solve the problems of buffer air bag filling and deflation time, convenient operation, logistics loading and working time, and large amount of buffer air bag, etc. , to achieve the effect of reducing misoperation and cumbersome actions, reducing transportation costs, and reducing packaging costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

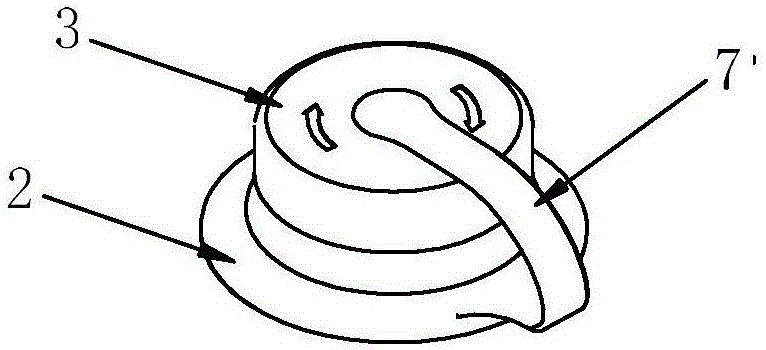

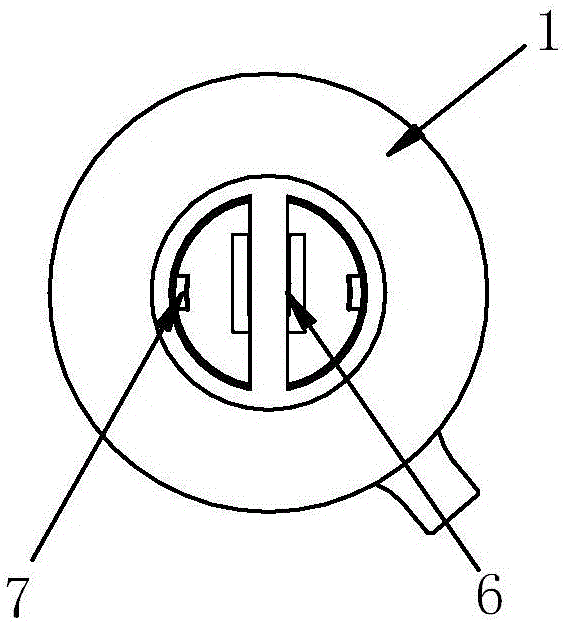

[0038] figure 1 Shown is a schematic diagram of the explosion structure of the present invention, including a valve body 1, a valve body pressing piece 2, a valve cover 3, a valve cover sealing ring 4, a valve piece 5 and a guide switch 6; the valve body pressing piece 2 is set on the valve body 1 , effectively covering the welding port of the valve body 1, beautiful and practical. The valve cover 3 is covered on the valve body 1, and the top surface of the valve cover is provided with a lock hole. The bonnet sealing ring 4 is placed in the bonnet 3, and the bonnet sealing ring 4 plays a secondary sealing effect. A supporting shaft is arranged in the cavity of the valve body 1, and the guide switch 6 is installed on the supporting shaft, and the valve plate 5 is installed on the supporting shaft.

[0039] Such as figure 2 and 9 As shown, the bonnet 3 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com