Reducer case

A technology of reducer and accessory casing, applied in mechanical equipment, components with teeth, gear lubrication/cooling, etc., can solve the problem that the reducer casing cannot have both bearing, oil circuit and air intake functions, etc. To achieve the effect of ensuring safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

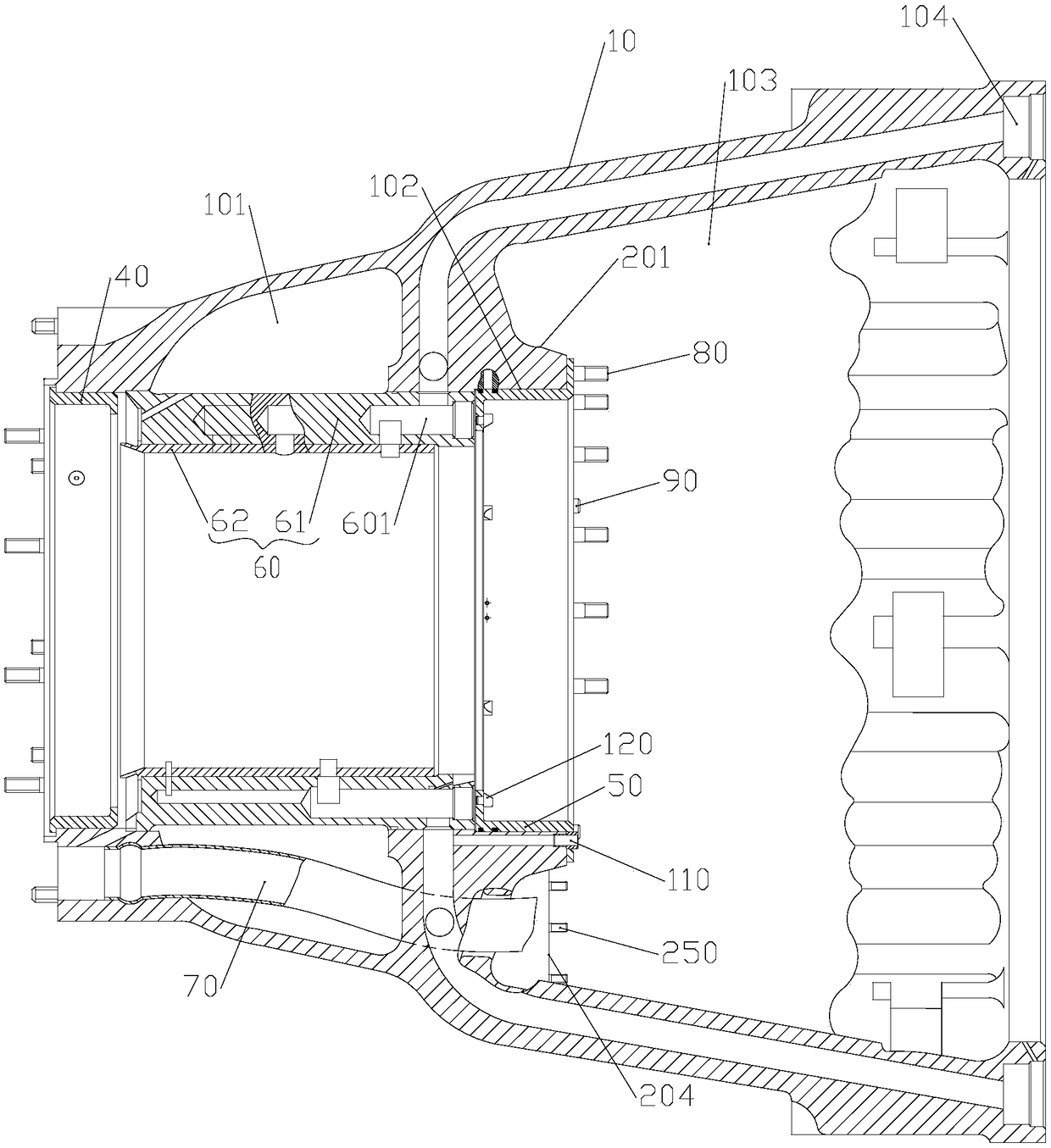

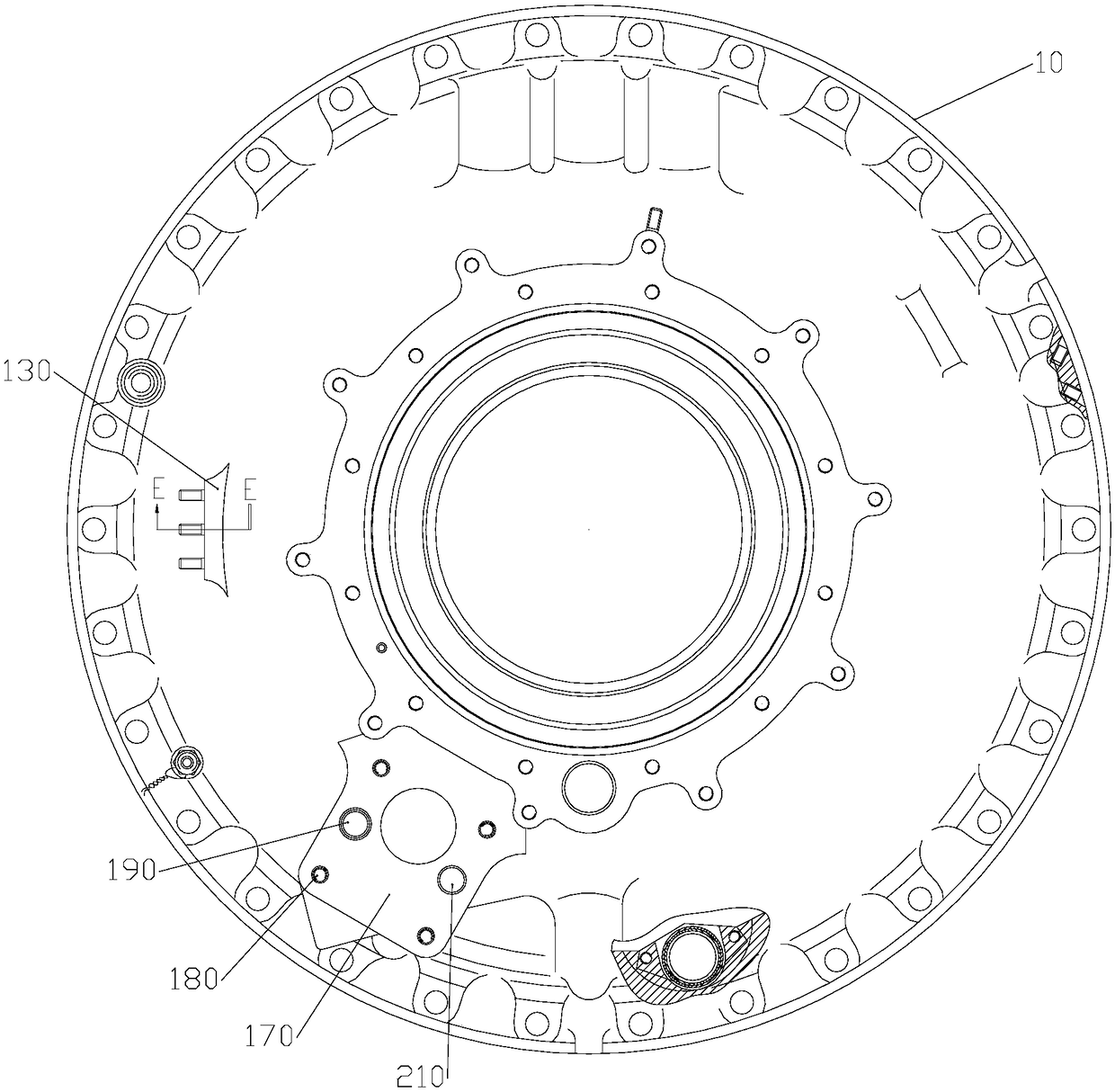

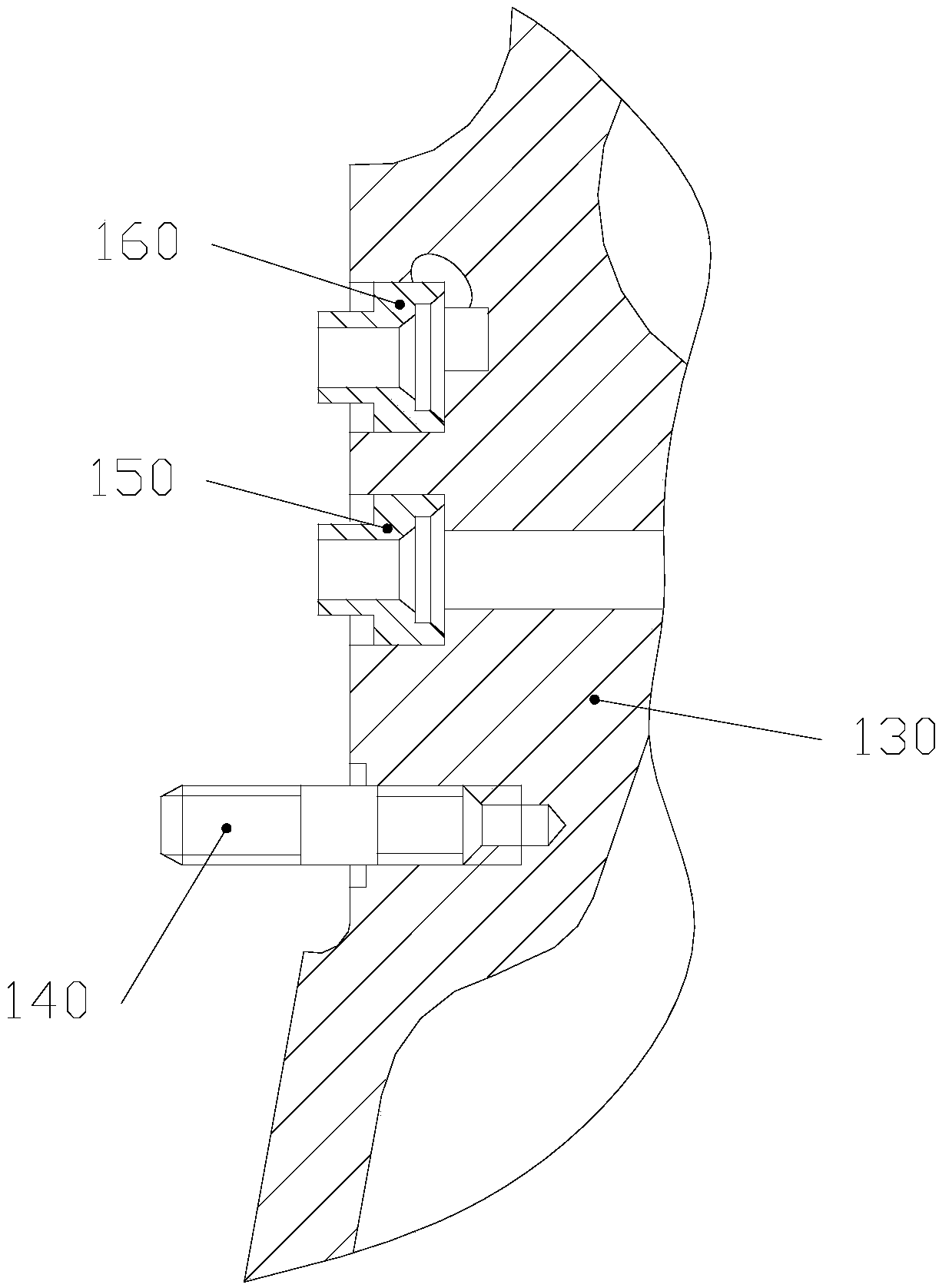

[0025] refer to Figure 1 to Figure 4, the preferred embodiment of the present invention provides a reducer casing, including a hollow cylindrical casing casing 10, one end of the casing casing 10 is used to connect the accessory casing (not shown) of the engine, and its opposite The other end provided is used to connect the inner fairing (not shown) of the engine intake to form the engine intake with the outer cowl (not shown) of the engine intake fixed on the accessory casing. The end of the casing 10 is provided with a plurality of installation holes 104 for installing the torsion measuring mechanism, and the casing 10 is sequentially provided with a connected front cavity 101, a middle cavity 102 and a rear cavity along its axis. Cavity 103, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com