Wheel machine with wheels provided with threads

A technology of rollers and threads, which is applied in the field of mechanical parts, can solve the problems of short service life, easy wear of crimping rollers, and low strength of crimping rollers, and achieve the effect of reducing design and production costs and being easy to replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

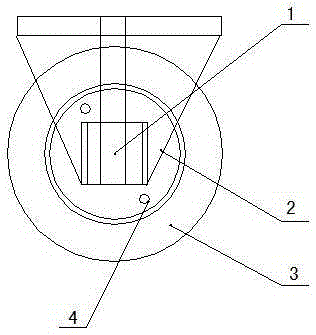

[0010] In order to facilitate the understanding of those skilled in the art, the structural principle of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings:

[0011] as shown in the picture 1 As shown, the present invention is a roller machine with thread on the roller, including a shaft head, a roller, and a cover plate, and is characterized in that: the roller includes a main roller and a side roller, and the side roller is sleeved on the main roller On the roller, the outer wall of the main roller is provided with an external thread, and the inner wall of the side roller is provided with an internal thread matching the external thread of the main roller.

[0012] The bottom of the adjustment seat is provided with a guide rail, the guide rail is provided with a slider, the slider is slidably connected to the guide rail, a bracket is provided on one side of the slider, the bracket is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com