A single-acting hydraulic cylinder with internal leakage display

A hydraulic cylinder and internal leakage technology, which is applied in the field of hydraulic cylinders, can solve problems such as external leakage and pollute the working environment, and achieve the effect of preventing external leakage of oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

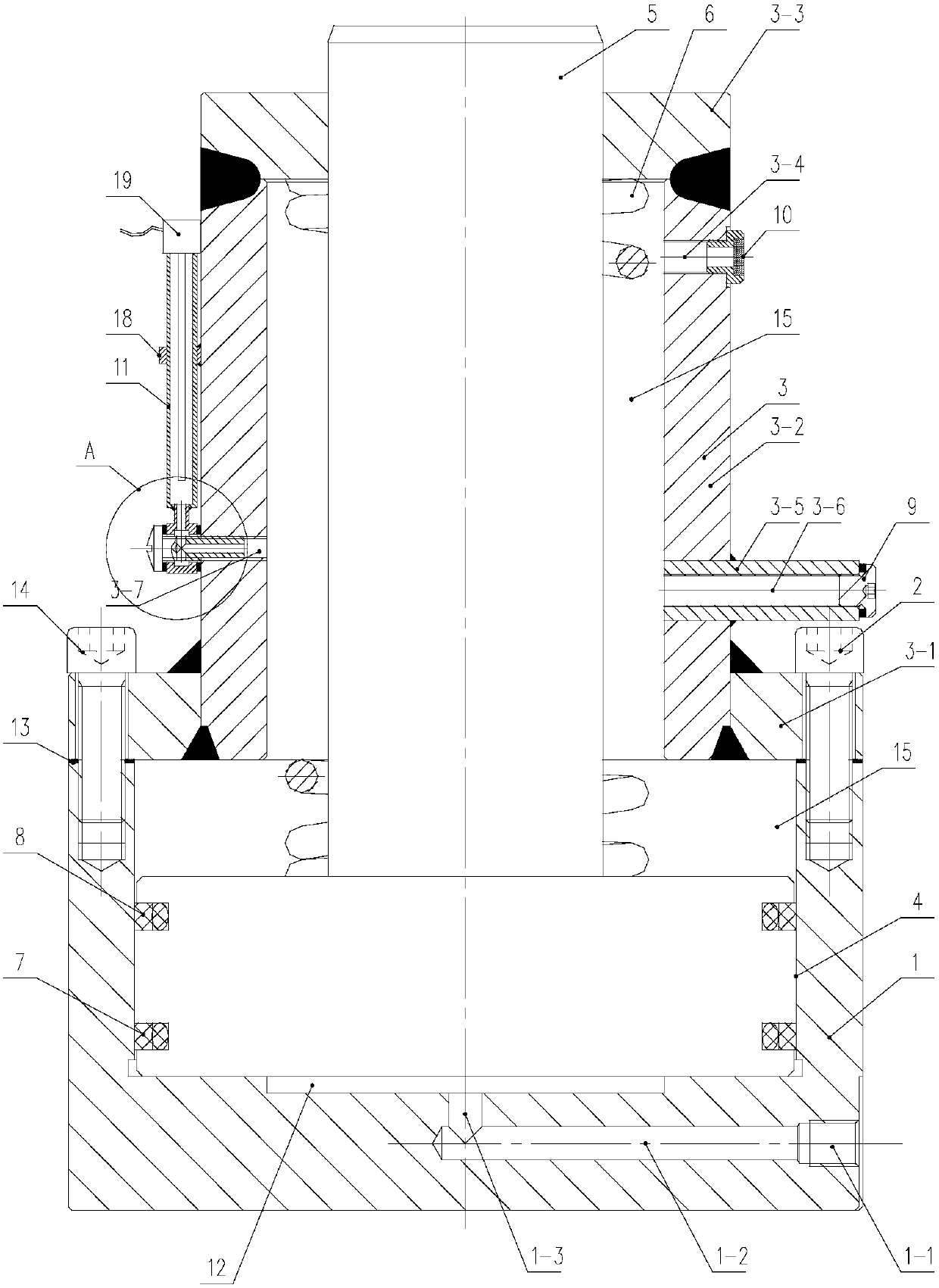

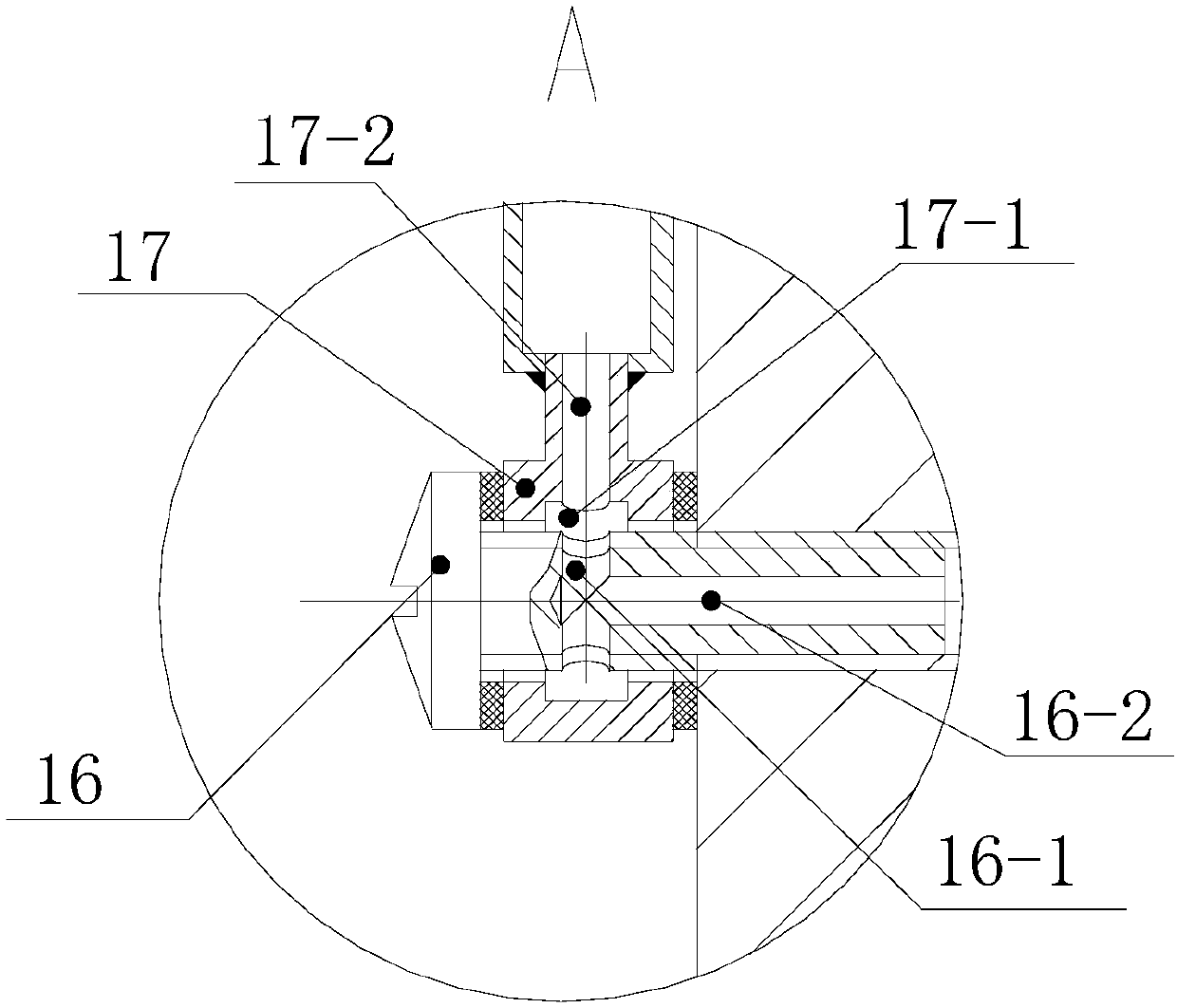

[0013] like figure 1 , figure 2 As shown, a single-acting hydraulic cylinder with internal leakage display includes cylinder body 1, first screw 2, second screw 14, upper end cover 3, piston 4, piston rod 5, spring 6, piston first seal 7, Piston second seal 8, plug 9, air filter 10, oil pipe 11, gasket 13, hollow screw 16, hinge joint 17, oil pipe bracket 18 and liquid level sensor 19; the cylinder body 1 is in the shape of "concave" , the lower part of the cylinder block 1 is provided with a hydraulic cylinder oil inlet 1-1, a hydraulic cylinder first oil passage 1-2 and a hydraulic cylinder second oil passage 1-3, and the hydraulic cylinder oil inlet 1-1 is located at The side wall of the cylinder block 1, the oil inlet port 1-1 of the hydraulic cylinder, the first oil passage 1-2 of the hydraulic cylinder, and the second oil passage 1-3 of the hydraulic cylinder communicate with the inside of the cylinder body 1, forming an "L" shape access; the upper end cover 3 is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com