Coal mine tunnel anti-explosion airtight gasbag

A technology for coal mine tunnels and airbags, applied in mining equipment, mining equipment, earthwork drilling and other directions, can solve the problems of rapid evacuation of disadvantaged personnel, cumbersome construction process, long construction time, etc., to save manpower and time, easy to operate process, The effect of saving operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

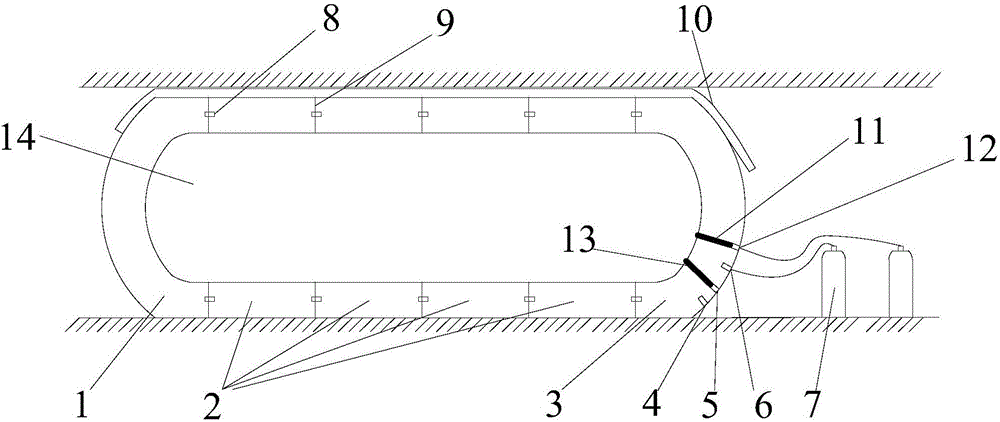

[0026] The present invention provides an explosion-proof airtight air bag for coal mine roadway. The technical solution of the present invention will be further described in detail below with reference to the accompanying drawings and examples, taking the technical application during the mining of the 2201 working face of a certain mine as the engineering background.

[0027] At first the airtight air bag proposed by the present invention is described as follows:

[0028] An explosion-proof airtight airbag for coal mine roadway, its overall shape is similar to a cylindrical rubber airbag, according to different specifications, its length is 4-6m, and the cross-sectional area is 8-14m 2 , its structure mainly includes: an inner airbag 14, an outer airbag, and a gas sample collection tube 10. Combined with the actual size of the 2201 working face along the channel, the cross-sectional area is selected to be 10m 2 , Explosion-proof airtight airbag with a length of 6m.

[0029] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com