Drilling drill pipe and drilling method for bionic flow pattern resistance reduction in coal and rock formations under complex geological conditions

A technology of complex geological conditions and coal rock formations, which is applied to drill pipes, drill pipes, earthwork drilling and mining, etc., can solve the problems of high drilling resistance, low drilling efficiency, and many drilling accidents, so as to reduce drilling resistance, The effect of improving drilling efficiency and increasing drilling depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

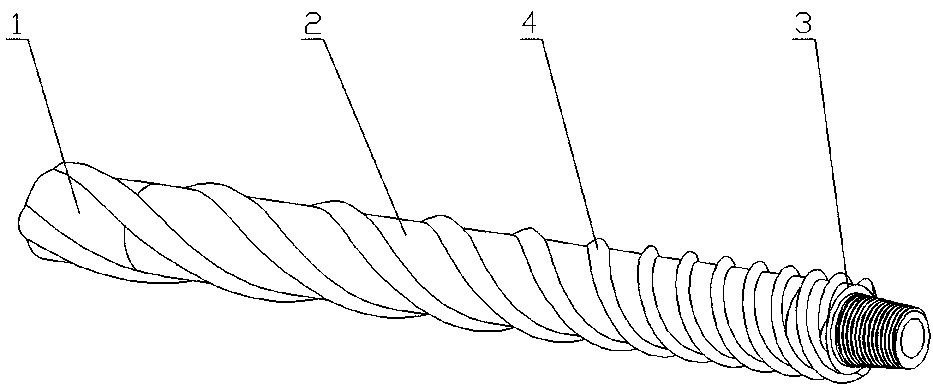

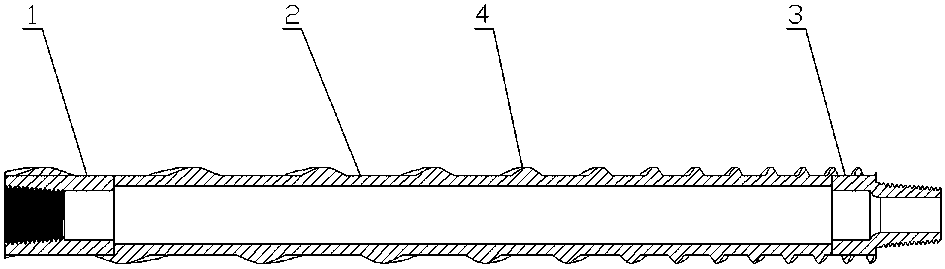

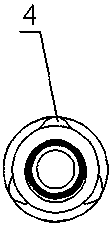

[0039] Example one: such as Figure 1 ~ Figure 3 As shown, the bionic rhyo-resistance-reducing drill rod for drilling into coal and rock formations under complex geological conditions of the present invention includes a bionic concave connector 1, a bionic hollow rod body 2, a bionic convex connector 3, a bionic concave connector 1, a bionic hollow rod body 2, a bionic The male connector 3 is coaxial, the bionic female connector 1 is connected to one end of the bionic hollow rod 2, the bionic male connector 3 is connected to the other end of the bionic hollow rod 2, the surface of the bionic female connector 1, the surface of the bionic hollow rod 2, and the bionic hollow rod 2 The surface of the male connector 3 is provided with a convex bionic flow pattern 4 or a concave bionic flow pattern 5 or a convex bionic flow pattern 4 and a concave bionic flow pattern 5 coexist.

[0040] The convex bionic flow pattern 4 or the concave bionic flow pattern 5 is set as a multi-head variable...

Embodiment 2

[0059] Embodiment two: such as Figure 4 ~ Figure 5 As shown, the difference from the first embodiment is that the surface of the drill rod is designed as a concave bionic flow pattern 5, and the use method of the second embodiment is the same as that of the first embodiment.

Embodiment 3

[0060] Embodiment three: such as Figure 6 ~ Figure 7 As shown, the difference from the first embodiment is that the convex bionic flow pattern 4 lead on the surface of the drill pipe is distributed along the axial direction of the drill pipe. The two ends are large and the middle is small. The use method of the third embodiment is the same as that of the first embodiment. Two are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com