Prestressed fabricated high-performance reinforced concrete beam-column joint and construction method thereof

A technology of reinforced concrete beams and reinforced concrete, applied in protective buildings/shelters, processing of building materials, construction, etc., can solve the problem of difficulty in ensuring joint strength and load transfer between beams and columns, inability to effectively consume earthquake action, Incorrect construction methods and other problems, to achieve the effect of easy quality control, improved ductility, and improved construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

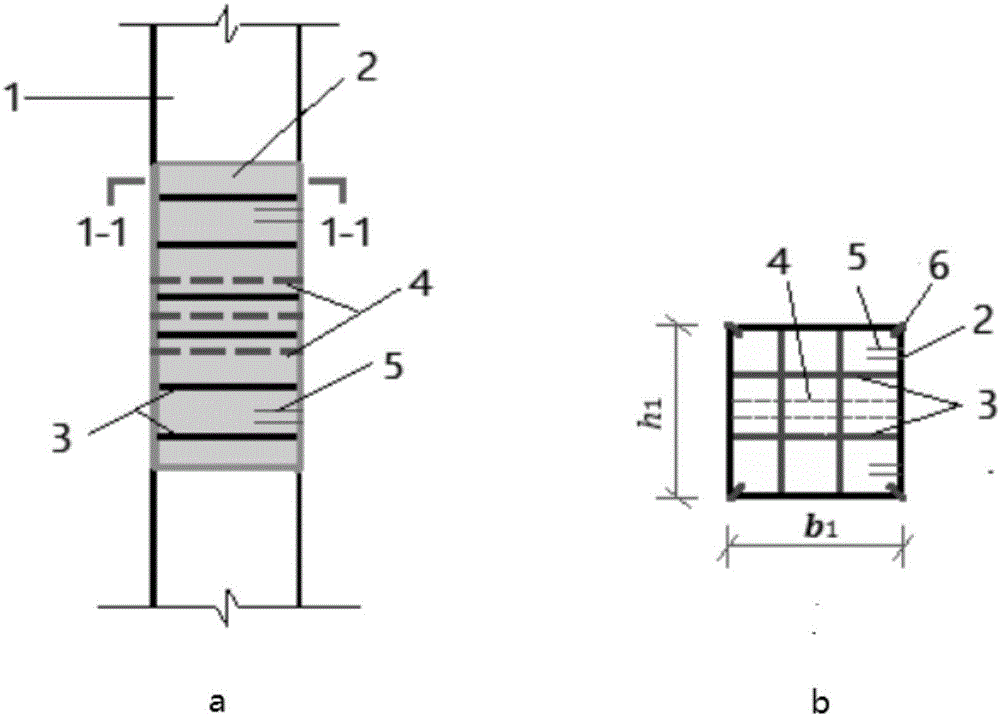

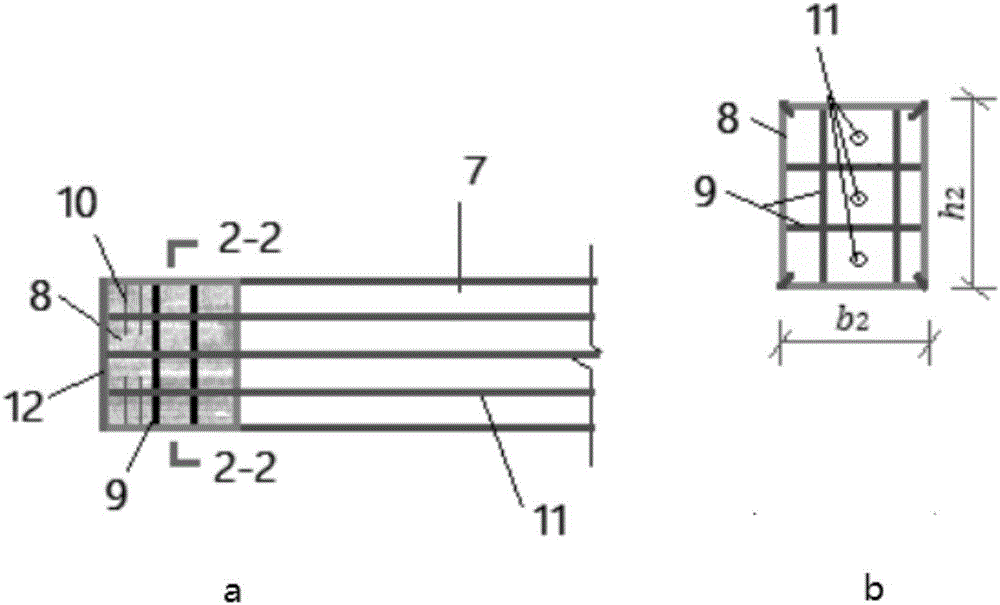

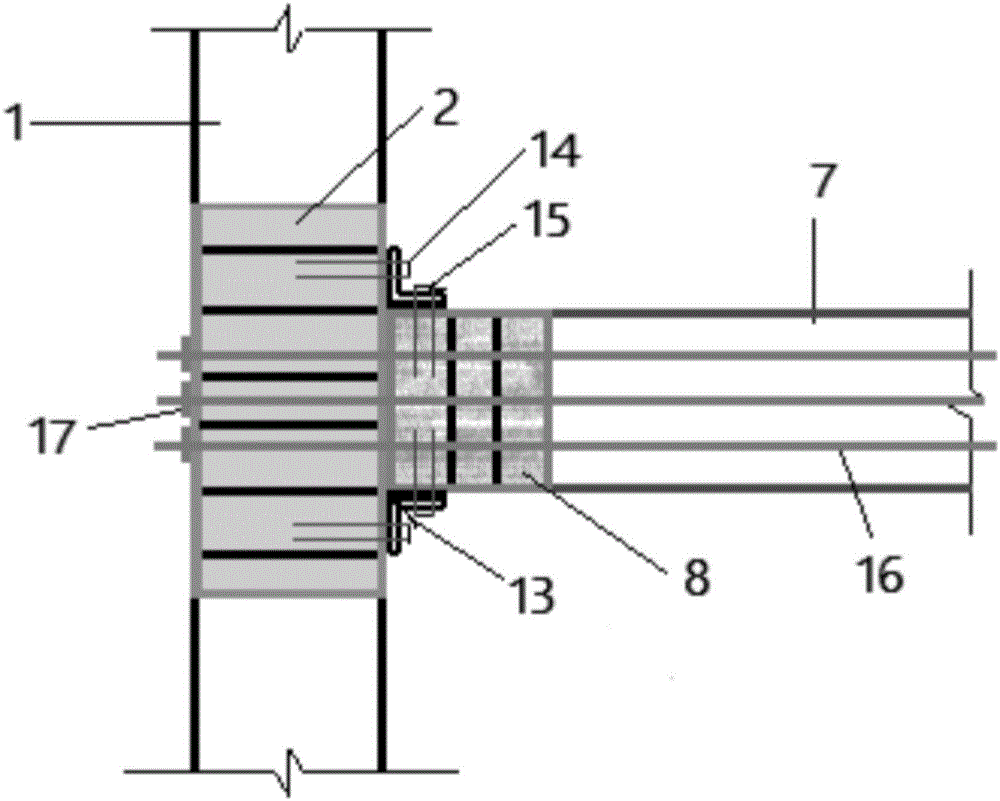

[0033] a Before pouring the concrete column, four steel plates with a thickness greater than 4mm are arranged on all sides of the connection between the column and the reinforced concrete beam, and the length of the four steel plates is greater than the height of the beam h 2 +80mm, the width is determined by the section size of the column, and the width of the two steel plates is the same as the section size of the reinforced concrete column b 1 The same, the width of the two steel plates is the same as the section size of the reinforced concrete column h 1 The same; the short steel bars directly larger than 12mm are used to connect the two opposite steel plates by welding, the number of short steel bars is not less than 3 layers, and each layer is not less than 2; no less than 2 prefabricated steel bars are reserved in the connection area with the reinforced concrete beam. Stress tendon channels are symmetrically arranged up and down. When the number of reserved prestress...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com