Octagonal pile leg provided with safe floating mechanism

A floating mechanism and octagonal pile technology, applied in the field of marine engineering, can solve problems such as deformation of pile legs, potential safety hazards, uneven force on pile legs, etc., and achieve the effects of uniform strength, increased service life, and high space utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions of the present invention are further described below with reference to the accompanying drawings and through specific embodiments.

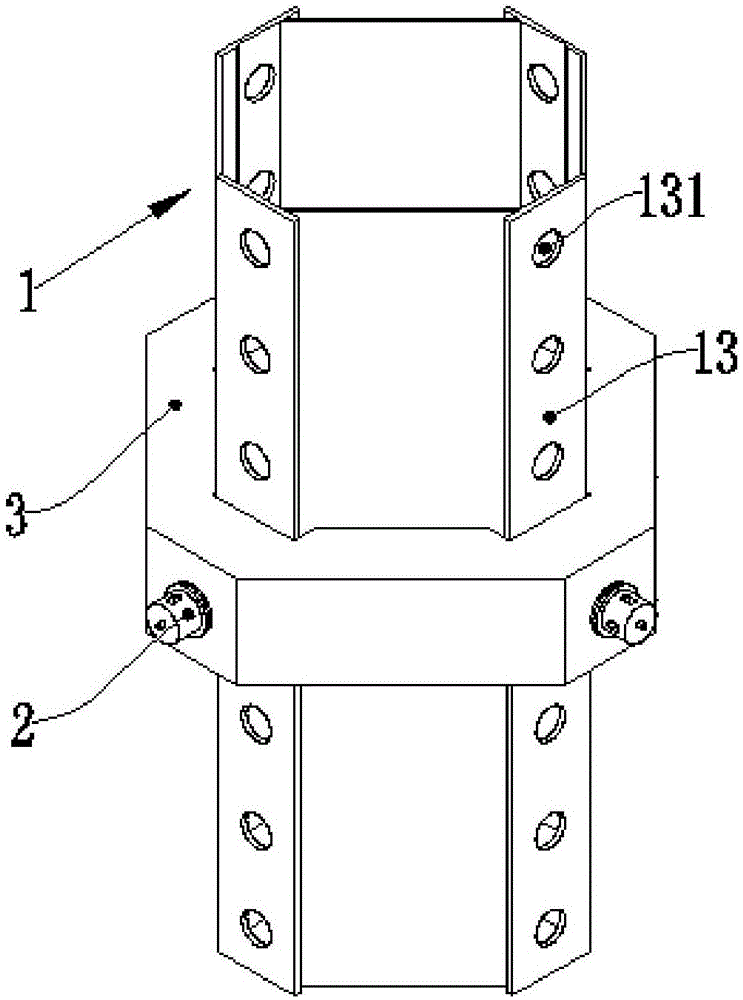

[0047] The octagonal leg with the safety floating mechanism of this embodiment, such as figure 1As shown, it includes a leg main body 1, a floating lock pin mechanism 2 and a lock pin installation ring beam 3, the lock pin installation ring beam 3 is sleeved outside the leg main body 1, and the floating lock pin mechanism 2 is installed Install the inner side of the ring beam 3 on the lock pin;

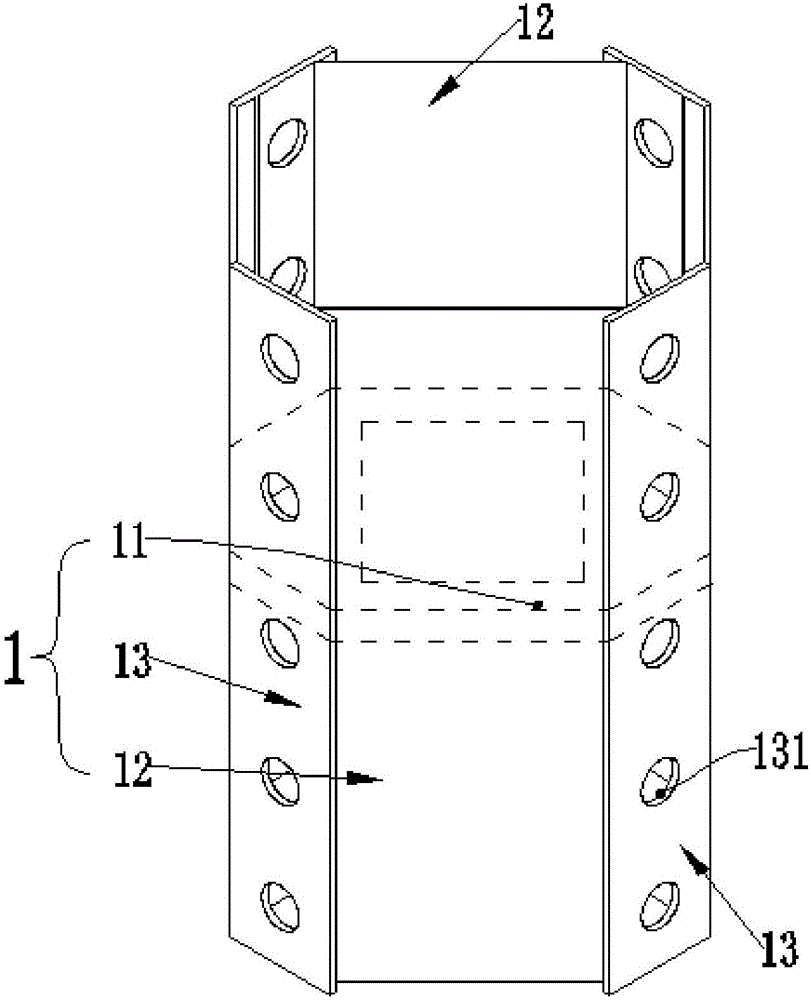

[0048] like figure 2 As shown, the leg main body 1 includes a platform partition 11, a shroud 12 and a guide plate 13, and the shroud 12 and the guide plate 13 are assembled into a shell of the leg main body 1, and the platform partition 11 is provided with inside the leg body 1;

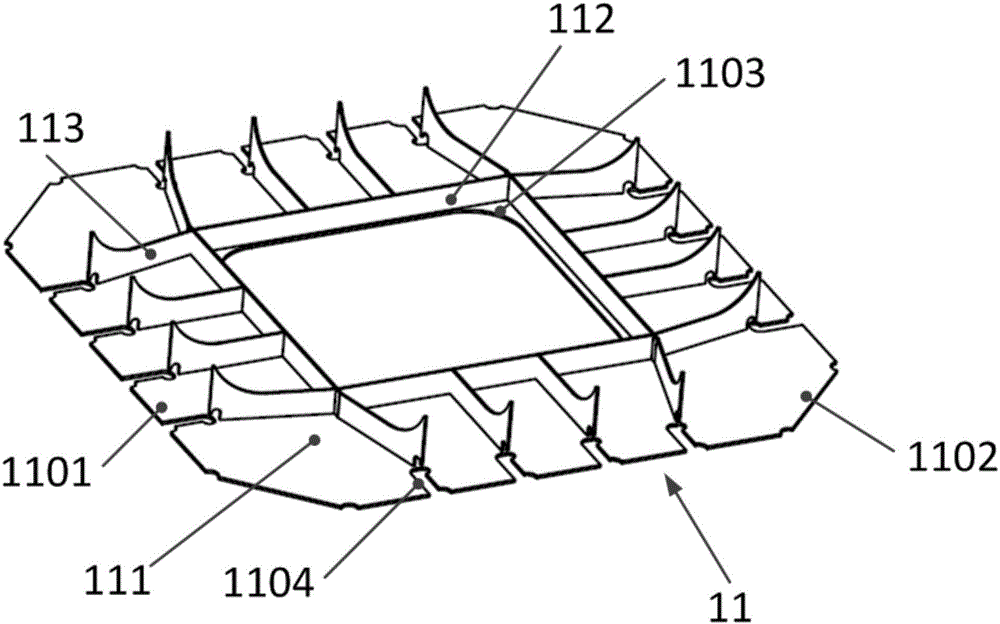

[0049] like image 3 As shown, the platform partition 11 includes a platform plate 111, a platform plate main rib 112 and a plurality of pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com