A method for preparing metal powder by electrodeposition

A metal powder and electrodeposition technology, applied in the field of electrochemistry, can solve the problems of difficult separation, time-consuming and labor-intensive peeling process, and high cost, and achieve the effects of solving emission pollution, improving utilization rate and increasing value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

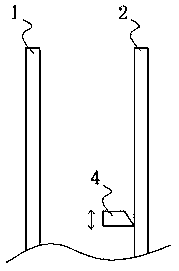

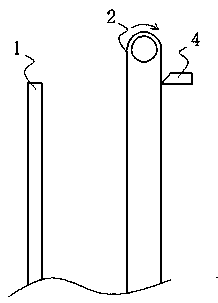

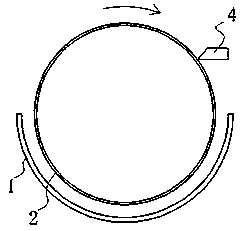

Image

Examples

Embodiment Construction

[0048] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

[0049] Any feature disclosed in this specification, unless specifically stated, can be replaced by other alternative features that are equivalent or have similar purposes. That is, unless expressly stated otherwise, each feature is one example only of a series of equivalent or similar features.

[0050] This embodiment provides a method for preparing metal powder by electrodeposition, which includes using graphite felt or carbon felt as the anode material to electrolyze the electrolyte. Due to the use of graphite felt or carbon felt as the anode, its large specific surface area enables the anode to obtain a large working current at a very small current density, showing characteristics different from traditional planar electrodes, and can overcome traditional dense anode materials. The "air cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com