Compound-flavor bacterial agent, preparation method thereof and direct-casting application thereof in sauce aroma enhancement

A technology for flavor bacteria and soy sauce, applied in biochemical equipment and methods, microorganism-based methods, bacteria, etc., can solve the problems of inability to produce products with strong flavor, complicated expansion process, affecting the effect of adding, etc., to improve the lack of flavor. , Control the production process, the effect of a large number of viable bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] 1. Compound Flavor Bacteria Products

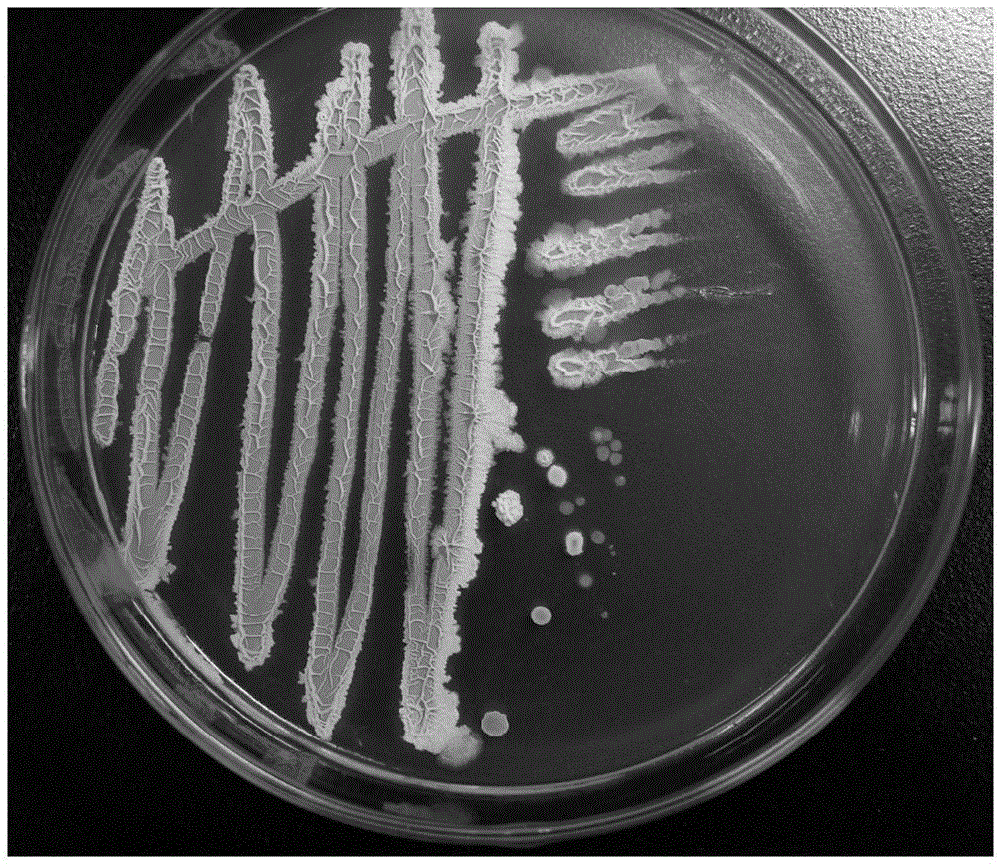

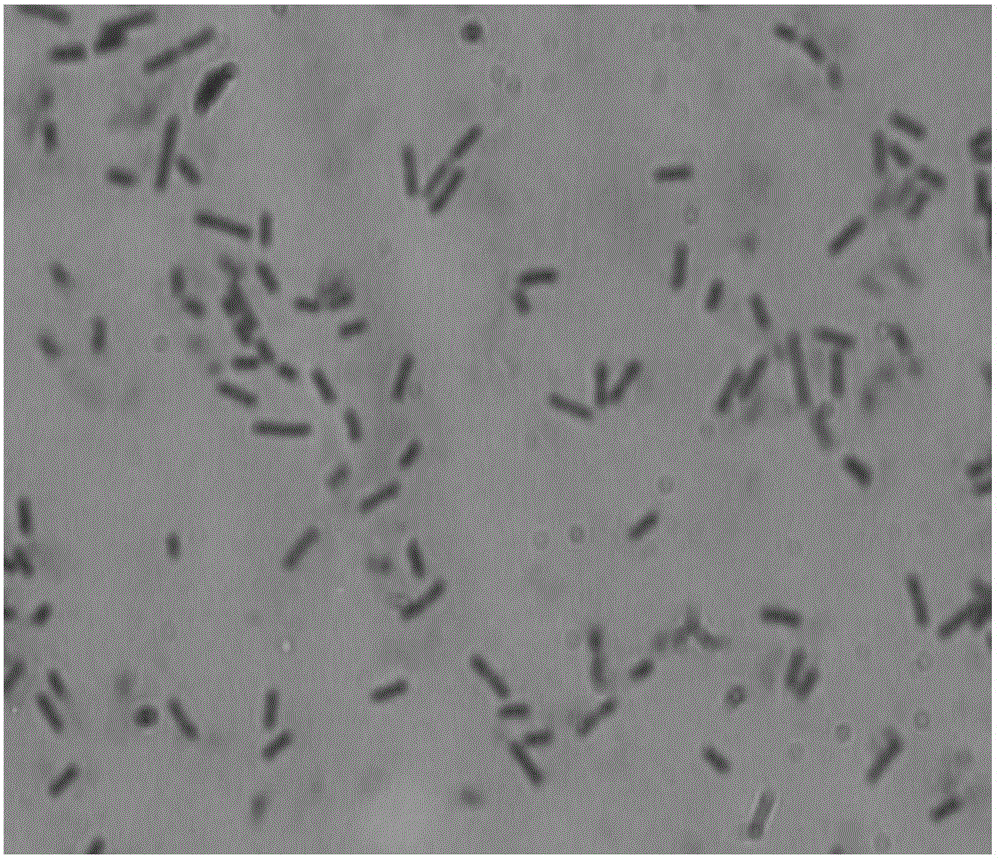

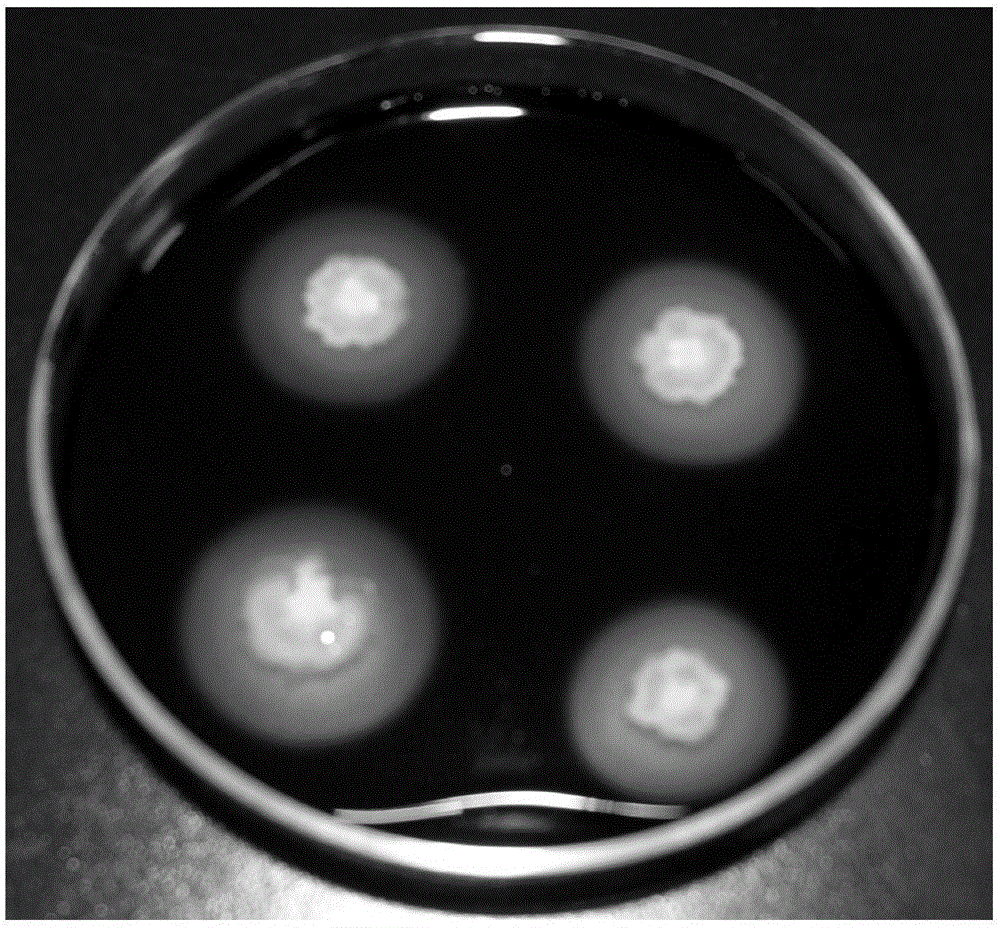

[0046] A compound flavor bacterial agent of the present invention is mainly prepared by mixing salt-tolerant Bacillus subtilis (Bacillus subtilis) bacterial powder and salt-tolerant Torulopsis yeast powder in a mass ratio of 1:1. The Bacillus subtilis bacteria powder is made from the Bacillus subtilis strain with the preservation number CCTCC NO: M 2015791, and the Bacillus subtilis bacteria powder is purchased from Angel Yeast Co., Ltd. S4 is made from raw materials.

[0047] The Bacillus subtilis bacterial strain that selects in the present embodiment is preserved in China Type Culture Collection Center (CCTCC for short), and it is called Bacillus subtilis CS1.03 (Bacillus subtilis CS1.03), and its preservation in China Type Culture Collection Center The number is CCTCC NO: M 2015791. The date of deposit of the Bacillus subtilis CS1.03 is December 29, 2015, and the address of the depository unit is located in Wuhan University, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com