Black rice thick wine production method

A technology of black rice thick wine and a production method, which is applied in the field of food fermentation and brewing, can solve the problems of easy loss of pigment degradation, low utilization rate of black rice, difficulty in saccharification and fermentation, etc., shortens the maturation time, is beneficial to saccharification, fermentation, and flavor. good taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

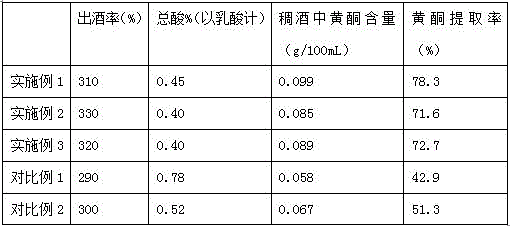

Examples

Embodiment 1

[0033] 1. a production method of black rice thick wine, comprises the following steps:

[0034] (1) Preparation of black rice soaking water: Soak black rice in 2.8 times the mass of water for 48 hours, take out and drain, then add water of 10 times the mass of black rice, pulverize and homogenize, filter with 200 mesh, and ferment the filtrate naturally at room temperature After 72 hours, filter to obtain the fermented sour pulp; add fermented sour pulp, acid protease (14U / mL) and cellulase (16U / mL) to the water, and adjust the pH value of the black rice soaking water with fermented sour pulp 4.1, Stir and mix evenly;

[0035] (2) Soak black rice: take 100g of black rice, mix black rice and black rice soaking water according to the material-to-liquid ratio of 40g: 100 mL, soak at 55°C for 220min, and measure the water absorption rate of black rice to be 39%;

[0036] (3) Concentration and purification of black rice pigment: separate the black rice from the black rice soaking ...

Embodiment 2

[0044] 1. a production method of black rice thick wine, comprises the following steps:

[0045] (1) Preparation of black rice soaking water: Soak black rice in 3.2 times the mass of water for 48 hours, take out and drain, then add water of 10 times the mass of black rice, pulverize and homogenize, filter with 200 mesh, and ferment the filtrate naturally at room temperature After 48 hours, filter to obtain fermented yogurt; add fermented yogurt, acid protease (amount of 18 U / mL) and cellulase enzyme preparation (amount of 22.5 U / mL) to water, and use fermented yogurt to adjust the concentration of black rice soaking water. The pH value is 4.5, stir and mix evenly;

[0046] (2) Soak black rice: take 100g of black rice, mix black rice and black rice soaking water according to the material-to-liquid ratio of 45g: 100 mL, soak at 58°C for 200min, and measure the water absorption rate of black rice to be 36%;

[0047] (3) Concentration and purification of black rice pigment: separa...

Embodiment 3

[0055] 1. a production method of black rice thick wine, comprises the following steps:

[0056] (1) Preparation of black rice soaking water: Add food grade lactic acid, acid protease (amount of 16 U / mL) and cellulase enzyme preparation (amount of 20 U / mL) to the water, and adjust the pH of black rice soaking water with fermented yogurt The value is 4.3, stir and mix evenly;

[0057] (2) Soak black rice: take 100g of black rice, mix black rice and black rice soaking water according to the material-to-liquid ratio of 43g: 100 mL, soak at 56°C for 210min, and measure the water absorption rate of black rice to be 37%;

[0058] (3) Concentration and purification of black rice pigment: separate the black rice from the black rice soaking water, drain and set aside, then heat the black rice soaking water at 80°C for 30 minutes, cool to room temperature, let stand for 24 hours, and filter to obtain rice Dregs and filtrate, rice dregs are used for subsequent fermentation of black rice,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com