Fluidized bed pyrolysis gasification device by adopting biomass gas recirculation process

A biomass gas, fluidized bed gasifier technology, which is applied in the gasification process, the manufacture of combustible gas, the petroleum industry, etc. The effect of reducing volatile matter and carbon residue, and small section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

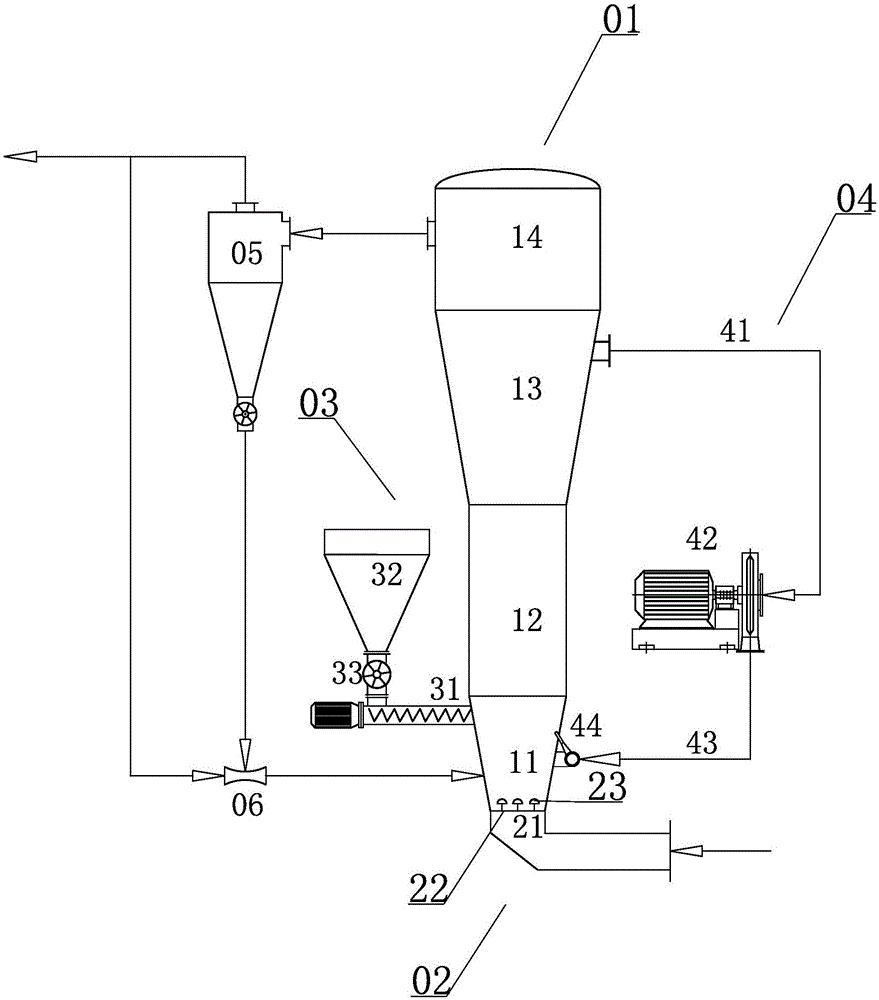

[0017] Below in conjunction with accompanying drawing, invention is described in further detail.

[0018] like figure 1As shown, a fluidized bed pyrolysis gasification device adopting a biomass gas recirculation process includes a fluidized bed gasification furnace body 01, a gasification gasification furnace provided on the bottom end of the fluidized bed gasification furnace body 01 agent supply structure 02 and the anti-leakage feed structure 03 provided on the side of the fluidized bed gasifier body 01, and the biomass gas circulation structure 04 provided on the fluidized bed gasifier body 01; The bed gasifier body 01 includes a cone heating section 11, a pyrolysis section 12 provided on the cone heating section 11, a cone diffuser section 13 provided on the pyrolysis section 12, and a cone diffuser section The settling section 14 is provided on the pressure section 13 . The gasification agent supply structure 02 includes an equal pressure air box 21 communicated with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com