Low-carbon environment-friendly foaming agent composition

一种低碳环保、组合物的技术,应用在有机化学等方向,能够解决整机能耗高、导热系数大、GWP值高等问题,达到降低导热系数、导热系数小、GWP值低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

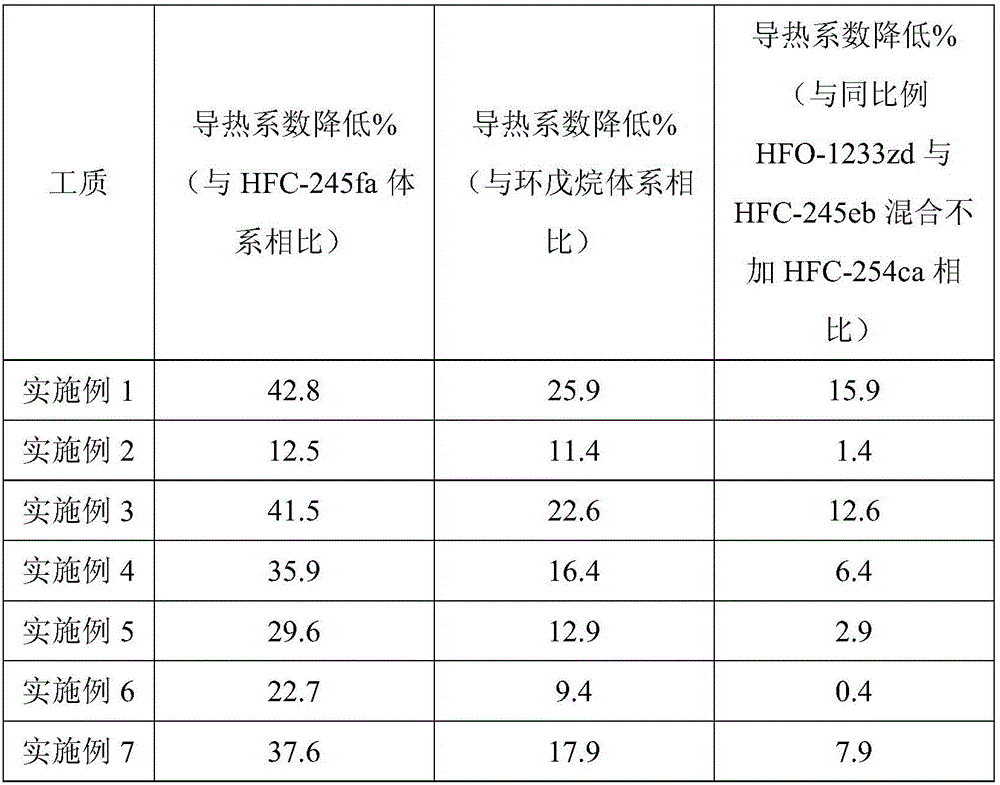

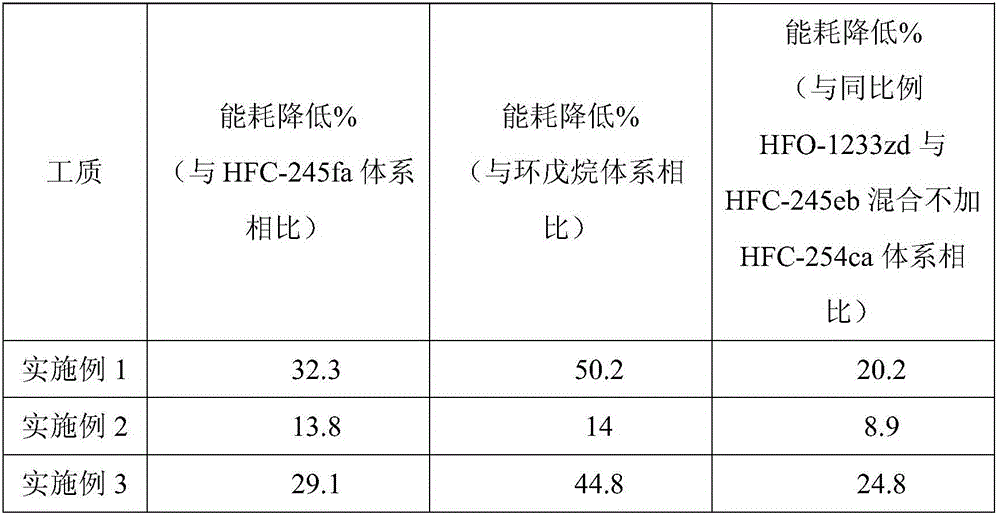

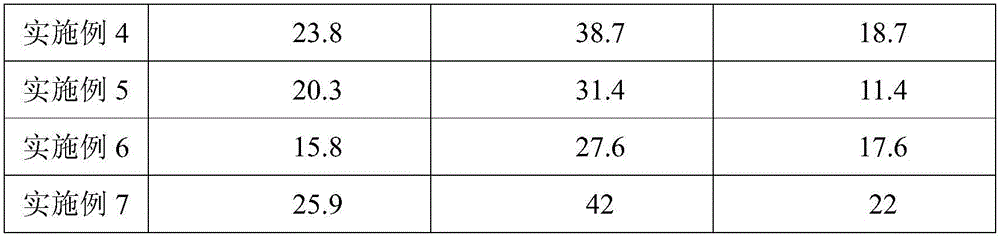

[0038] Mix 600 grams of HFO-1233zd, 399 grams of HFC-245eb and 1 gram of HFC-254ca in a steel cylinder under the liquid phase to obtain a low-carbon and environmentally friendly blowing agent composition. The mass percentage of HFO-1233zd is 60%, and HFC The mass percentage content of -245eb is 39.9%, and the mass percentage content of HFC-254ca is 0.1%. Its performance was tested, and the results are shown in Tables 1-3, wherein the low-carbon environment-friendly blowing agent composition has a boiling point of 18.3°C at 101.3KPa.

Embodiment 2

[0040] Mix 989.9 grams of HFO-1233zd, 10 grams of HFC-245eb and 0.1 grams of HFC-254ca in a steel cylinder under the liquid phase to obtain a low-carbon and environmentally friendly foaming agent composition. The mass percentage of HFO-1233zd is 98.99%, and HFC The mass percentage content of -245eb is 1%, and the mass percentage content of HFC-254ca is 0.01%. Its performance was tested, and the results are shown in Tables 1-3, wherein the low-carbon environment-friendly blowing agent composition has a boiling point of 18.9°C at 101.3KPa.

Embodiment 3

[0042] Mix 699 grams of HFO-1233zd, 300 grams of HFC-245eb and 1 gram of HFC-254ca in a steel cylinder under the liquid phase to obtain a low-carbon and environmentally friendly blowing agent composition. The mass percentage of HFO-1233zd is 69.9%. HFC The mass percentage content of -245eb is 30%, and the mass percentage content of HFC-254ca is 0.1%. Its performance was tested, and the results are shown in Tables 1-3, wherein the low-carbon environment-friendly blowing agent composition has a boiling point of 18.5°C at 101.3KPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com