A method for manganese and iron removal by oxidation filtration of high ph source water

A source water, pre-oxidation technology, applied in the direction of chemical instruments and methods, filtration treatment, oxidized water/sewage treatment, etc., can solve the problems of poor pre-oxidation effect, chlorite and chlorate, easy to produce chroma, etc. , to achieve the effect of less dosage, enhanced water purification function, and good water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Materials

[0024] The methods used in this embodiment are all conventional methods known to those skilled in the art unless otherwise specified, and the materials such as reagents used, if not otherwise specified, are commercially available products, and meet the quality standards of medicaments used in water purification plants .

[0025] 2. Method

[0026] The method for manganese and iron removal by oxidation, filtration, and manganese removal of the high pH source water, the overall process flow is:

[0027] Source water → primary pumping station → distribution well → pre-oxidation tank → first reaction tank (coagulation) → high-density sedimentation tank → filter tank → clear water tank → secondary pumping station → user, the above process will be described in detail below .

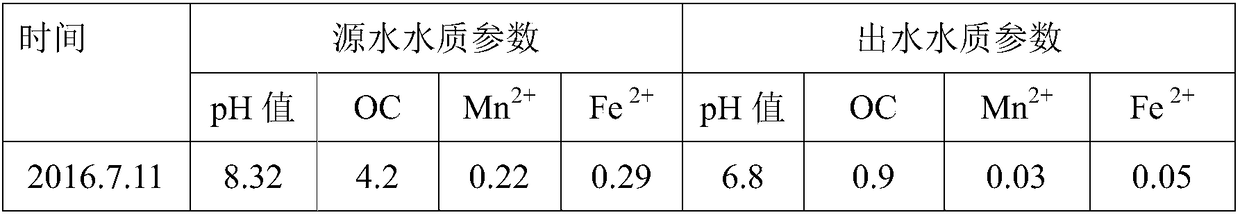

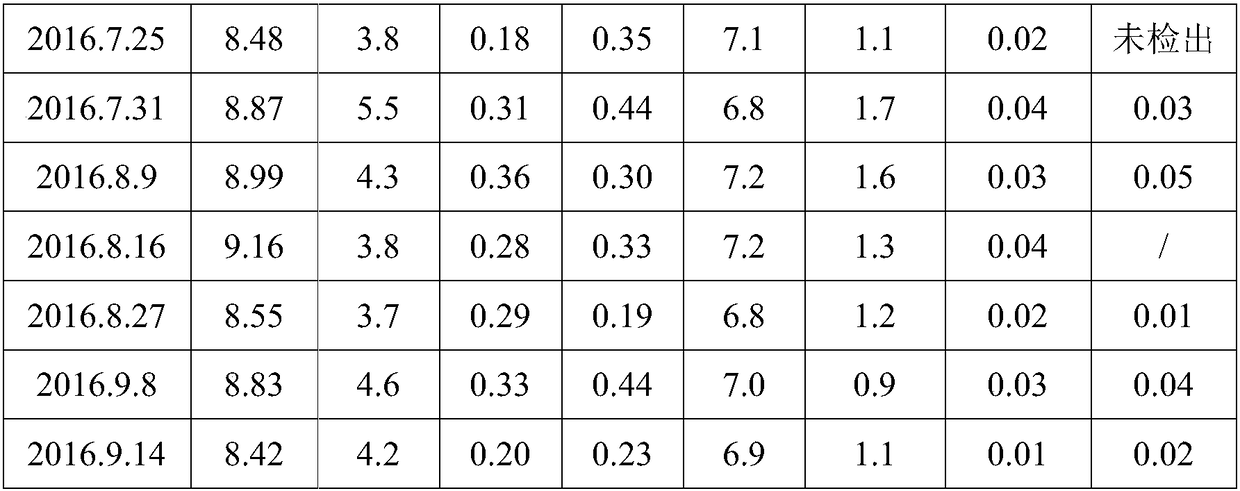

[0028] 2.1 Determination of source water quality parameters

[0029] Including pH value, OC value (mg / L), Mn 2+ Content (mg / L), Fe 2+ Content (mg / L), the determination method all ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com