Push-lock type unpowered container spreader

A container spreader and push-lock technology, which is applied in the spreader field, can solve the problems of complex structure, high cost, and increase the weight of the spreader, and achieve the effects of easy manufacture, simple structure and reasonable stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited.

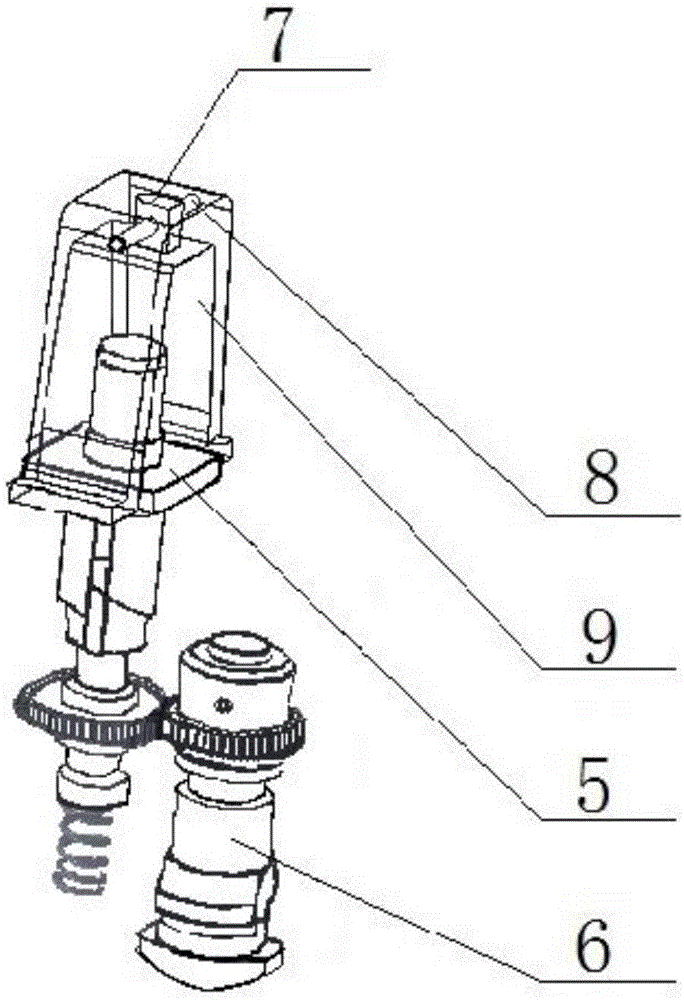

[0030] The push-lock type unpowered container spreader provided by the present invention has a structure such as figure 1 and figure 2 As shown, it includes a spreader frame 4, a main steel wire rope 1, an auxiliary steel wire rope 2, and a twist lock operating mechanism 3, wherein: there are four twist lock operating mechanisms 3, which are respectively located on the four corners of the spreader frame 4, and the spreader frame 4 and The stiffness and strength of the main steel wire rope 1 and the auxiliary steel wire rope 2 meet the actual work requirements, and the four main steel wire ropes 1 and the four auxiliary steel wire ropes 2 must be arranged symmetrically. There are 8 wire ropes in the whole spreader, among which 4 auxiliary wire ropes are connected to the push lock assembly and the lifting rope o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com