Container, hinged connection structure of container, and hinge assembly

A hinge assembly and component technology, applied in the hinge field, can solve the problems of easy accumulation of dirt, inconvenient disassembly and assembly, and damage to the appearance of the container.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

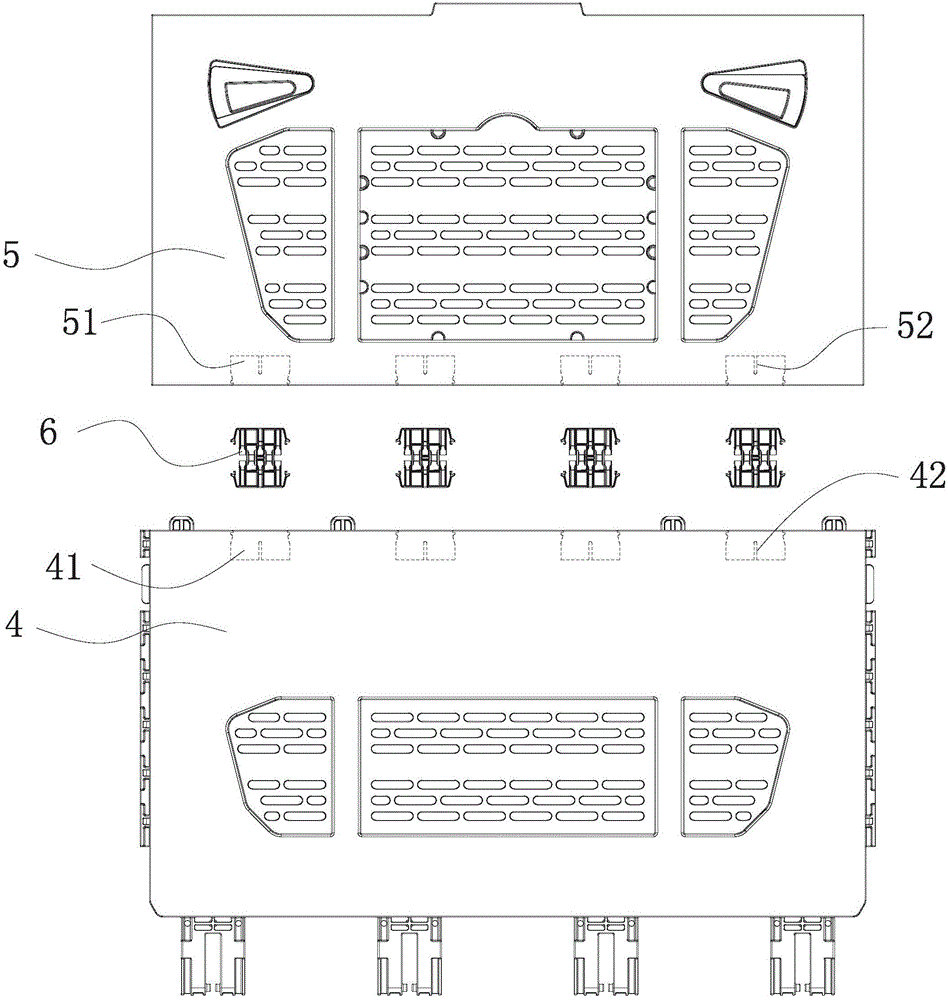

[0050] figure 1 It shows a thin-plate container adopting the hinge structure of the first embodiment of the present invention, such as a retail display unit (Retail Display Unit). like figure 1 As shown, the container comprises a base 1 and two pairs of side panels 2,4. Also have wicket 3,5 on each side plate 2,4. The small doors 3,5 and the side panels 2,4 are connected by several groups of hinge structures, so that the small doors 3,5 can be opened relative to the side panels 2,4. It should be understood that the hinge structure of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com