Automatic carton packaging system

A packaging system, fully automatic technology, applied in packaging, transportation and packaging, packaging/bundling items, etc., can solve the problem of inability to meet mechanical automation, simplicity, low cost, high efficiency, unguaranteed production efficiency, unreasonable structure, etc. problems, to avoid semi-automatic operations, improve the quality of life, and humanized design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

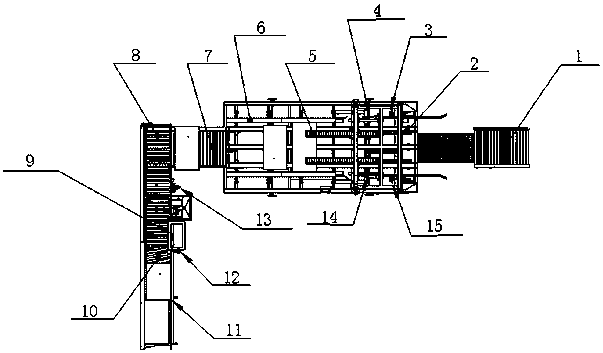

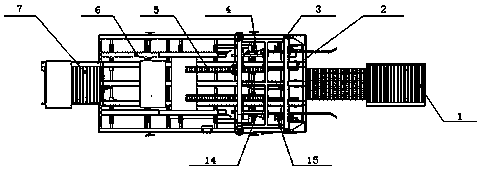

[0036] see figure 1

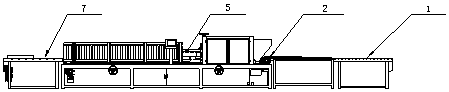

[0037] figure 1 It is a top view of the present invention. exist figure 1 Among them, the fully automatic carton packaging system includes a conveyor belt 2 connected to a driving device through a roller 1, a spray gun 3 and a spray gun 2 15 are provided on both sides of the conveyor belt 2, and an inclined body 4 is provided behind the spray gun 3 , the rear of the spray gun two 15 is provided with an inclined body two 14, the rear of the inclined body one 4 is provided with a drum two 5 and a drum three 6, and the rear of the drum three 6 is provided with a drum four 7 and a drum five 8, the The flank of cylinder five 8 is provided with spray gun three 13, and the rear of described spray gun three 13 is provided with inclined body three 9 and regulating valve 12, and described regulating valve 12 rear is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com