Rubber sole injection mold and injection molding method

A technology for rubber soles and injection molds, applied in footwear, household appliances, other household appliances, etc., can solve the problems of long production lines, inability to adapt to sewing leather or fabric uppers, and high labor costs, so as to improve production efficiency and save money. Labor cost, saving effect of laminating steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

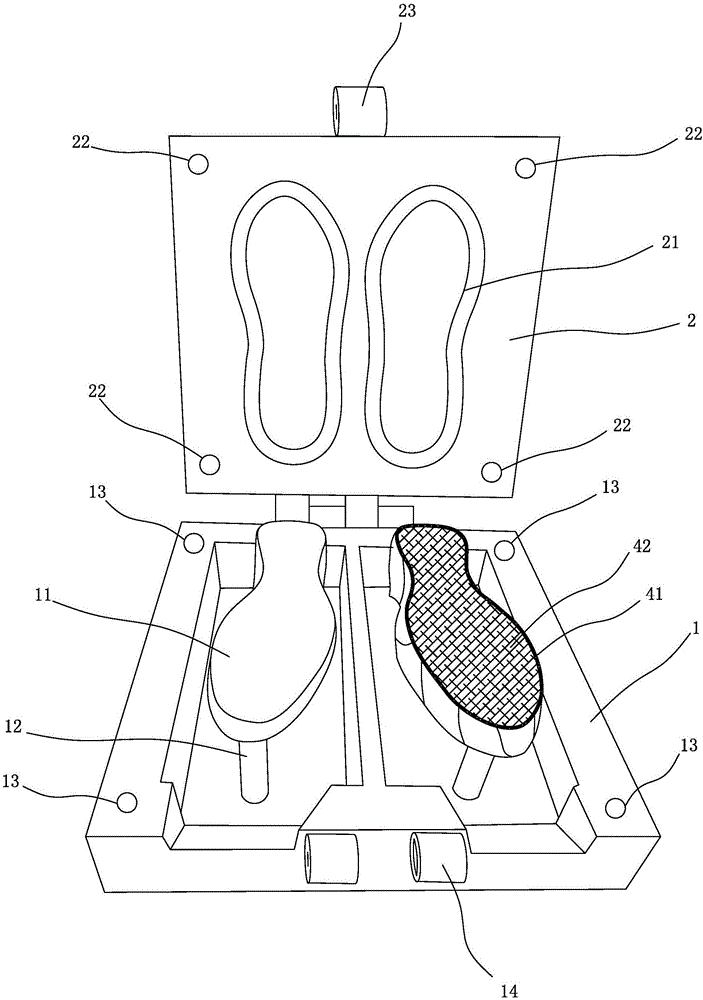

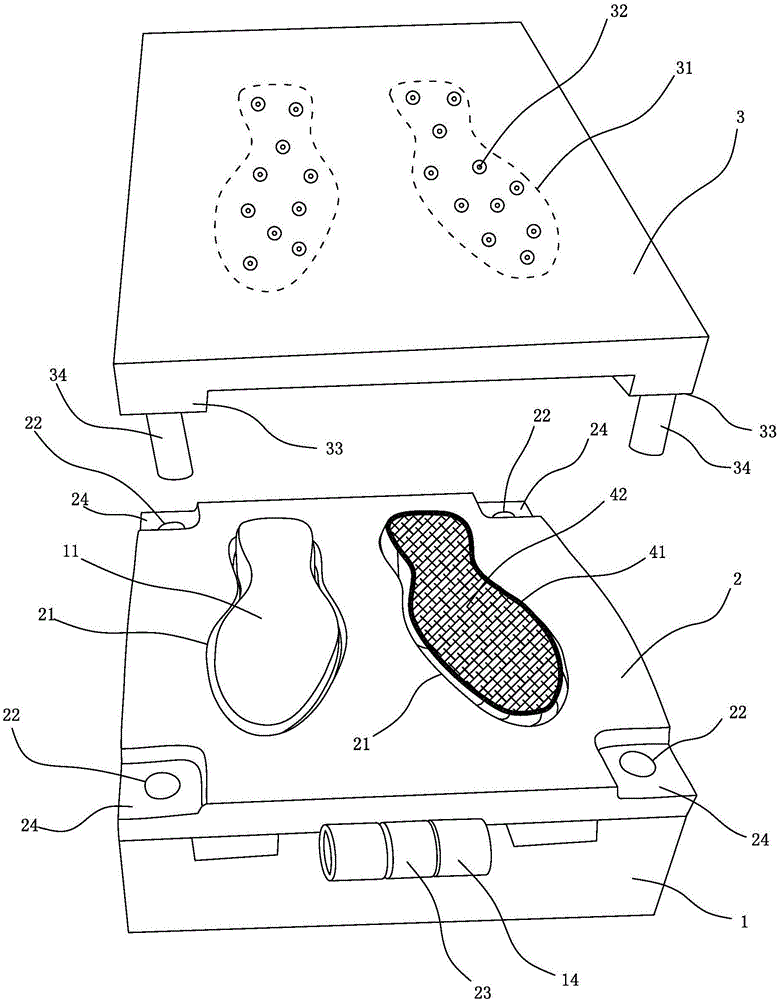

[0024] refer to figure 1 with figure 2 As shown, a rubber sole injection mold includes an upper mold 3, a middle mold 2, and a lower mold 1 that can be closed sequentially. The upper mold 3, the middle mold 2, and the lower mold 1 are all roughly rectangular, and the mold is rectangular after mold closing body.

[0025] The lower mold 1 is provided with a shoe last 11 that can be fitted with a shoe upper 41. The shoe last 11 is supported in the lower mold 1 by two columns 12. The middle mold 2 is formed with a shoe upper peripheral tightening hole 21 that penetrates up and down. The upper mold 3 is formed with a shoe sole. The molding groove 31 and the injection hole 32 connected to the molding groove 31 of the sole, when the mold is closed, the hole 21 around the shoe upper and the shoe last 11 tighten the shoe upper 41, and the middle mold 2, the shoe last 11, the shoe upper and the shoe sole are formed The groove 31 surrounds a closed shoe sole mold cavity, and the perip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com