Variable-diameter variable-pitch spiral vertical planetary mixer

A technology of planetary mixers and spirals, applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve problems affecting concrete mixing quality and production efficiency, low mixing efficiency and low mixing efficiency areas, etc., and achieve low cost of use , high mixing efficiency, convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

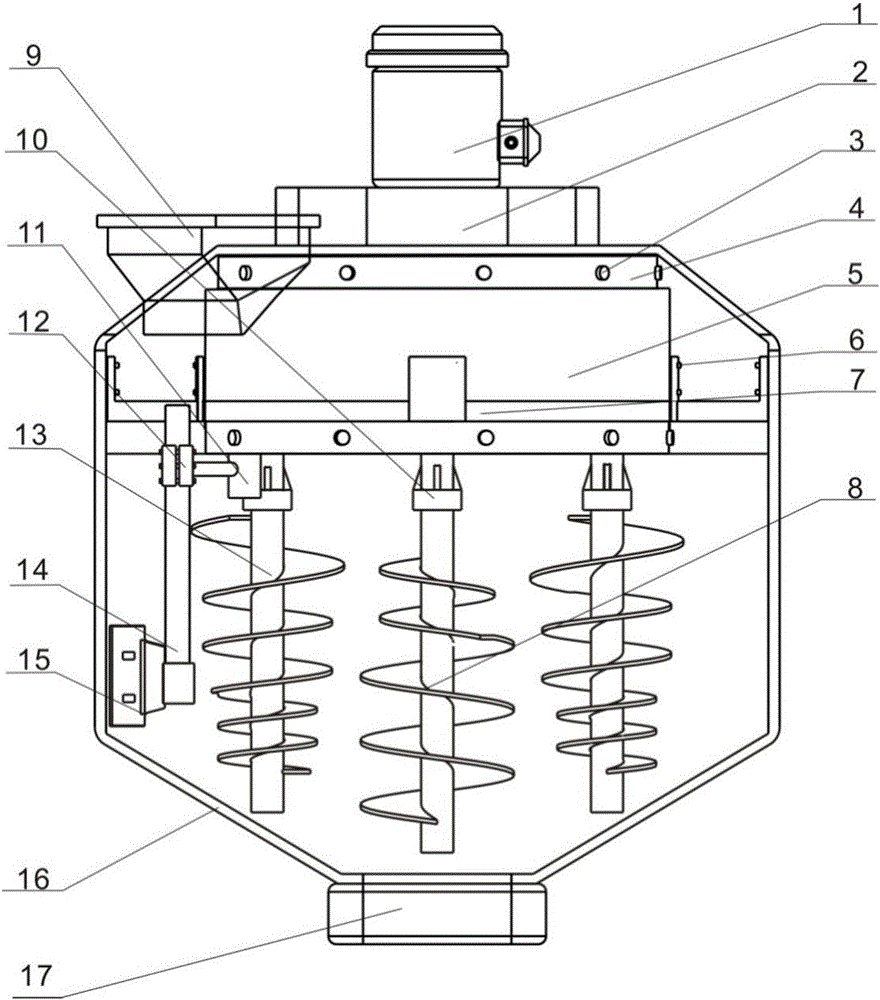

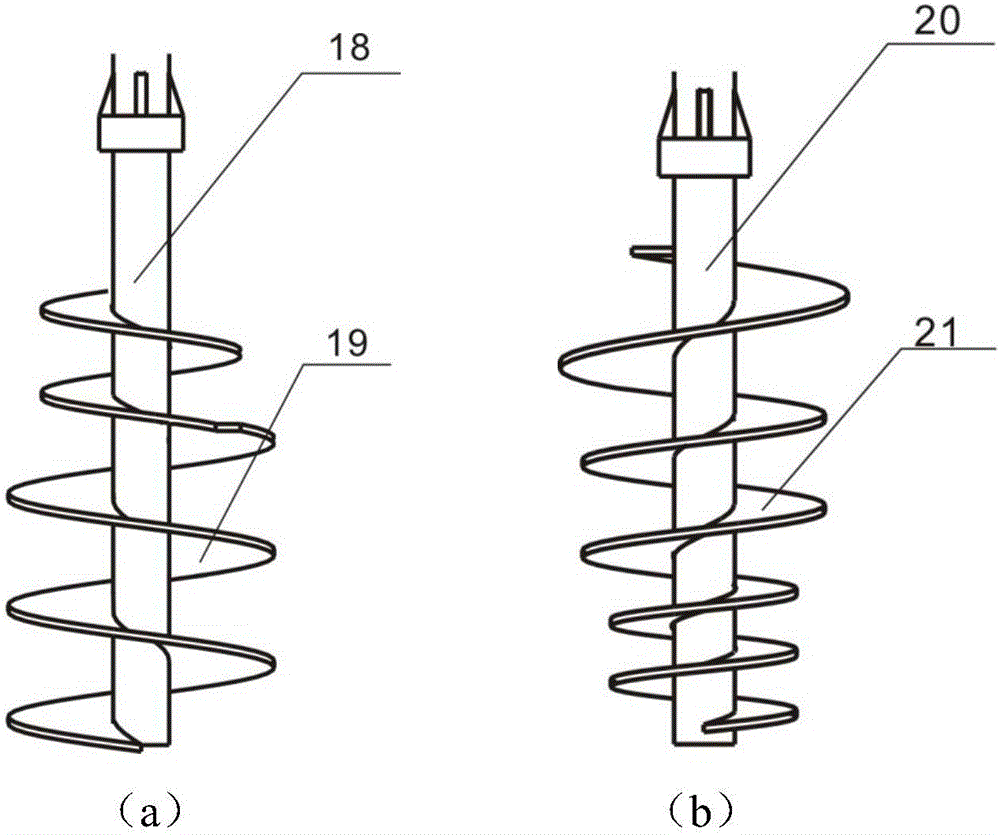

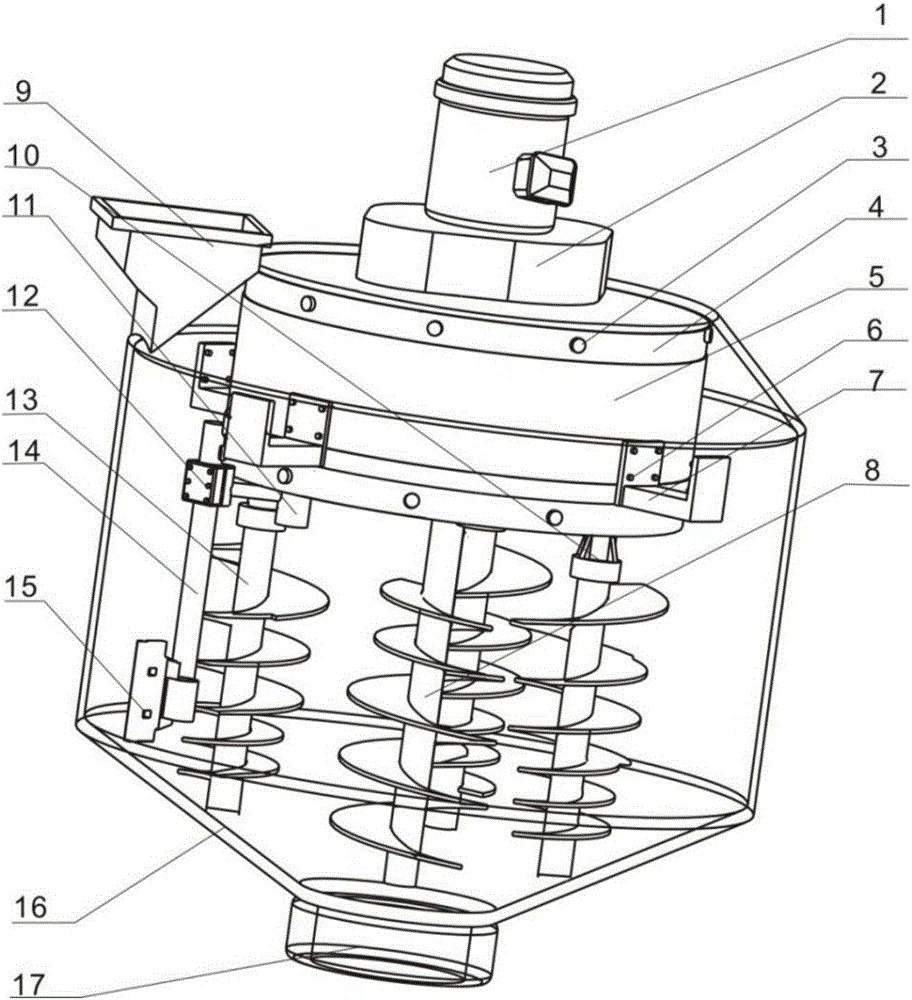

[0031] The present invention is described in further detail below in conjunction with accompanying drawing:

[0032] see figure 1 , the variable-diameter variable-pitch planetary stirring device of the present invention is provided with a cylinder 16, the cylinder 16 is fixedly connected with the feed inlet 9, the cylinder 16 is fixedly connected with the discharge port 17, the motor 1 is fixedly connected with the reducer 2, and the deceleration The device 2 is fixedly connected with the cylinder body 16, the sealing cover 4 is fixedly connected with the planet carrier 23 of the planetary gear device 5 through the bolt 3, the reducer 2 is connected with the planetary gear device 5, and the inner gear 22 of the planetary gear device 5 and the connecting plate 6 pass through The bolts are fixed, the connecting plate 6 is fixed with the support plate 7, the support plate 7 is connected with the cylinder 16 through bolts, the central screw 8 and the planetary screw 13 pass throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com