Automatic balance adjusting system for rotating table

An automatic adjustment and balance system technology, applied in the workbench, program control in the sequence/logic controller, manufacturing tools, etc., can solve the problems of the turntable vibration, affecting the production efficiency, the adjustment accuracy is not stable enough, etc., to achieve accurate adjustment, Good effect of automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

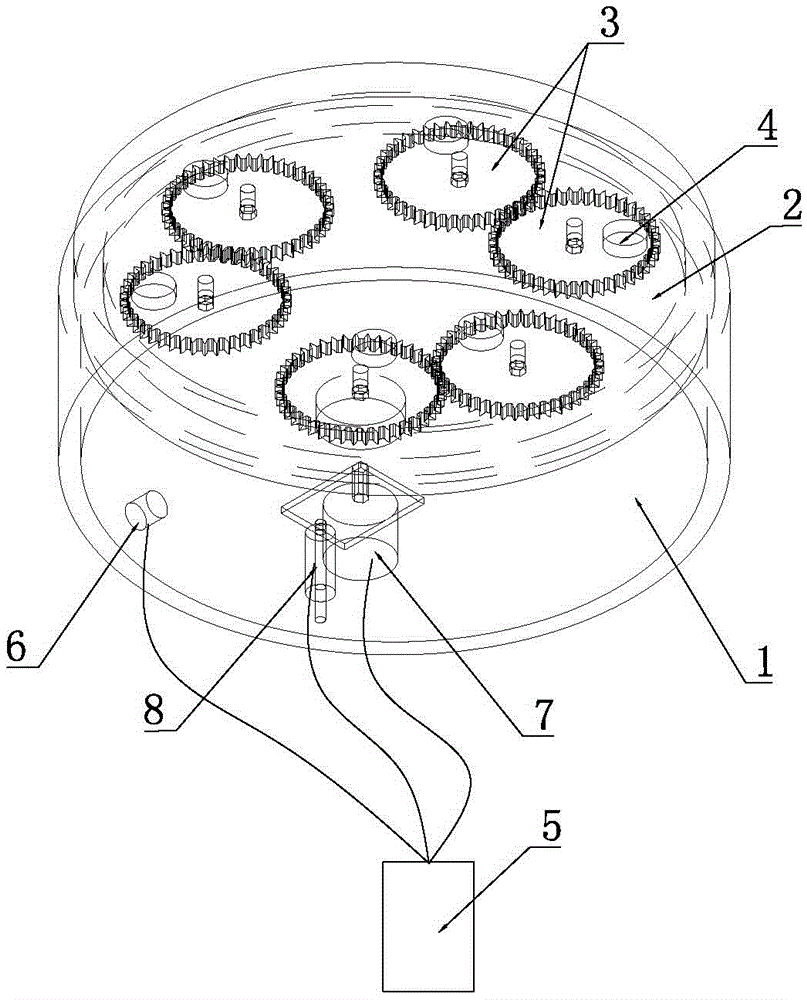

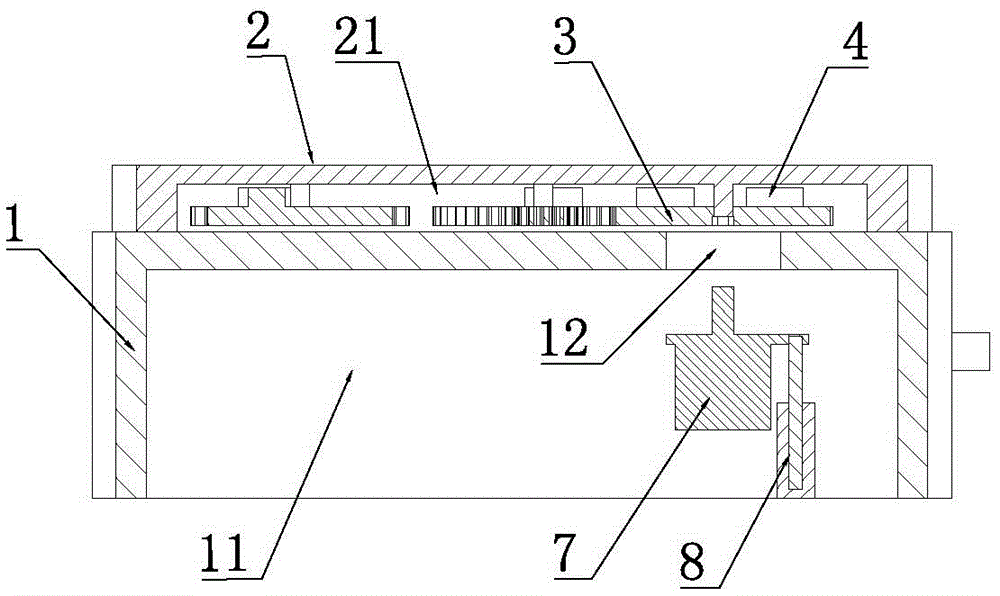

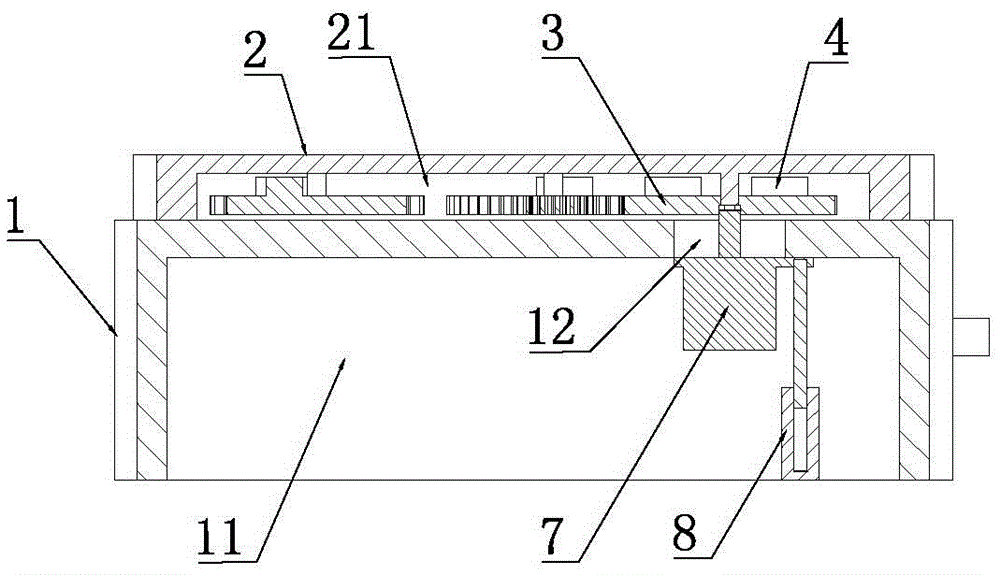

[0030] A kind of rotating platform automatic adjustment balance system of this embodiment, such as figure 1 and figure 2 As shown, the structure includes a base 1 and a turntable 2, the turntable 2 is installed on the base 1, the workpiece is placed on the turntable 2, the turntable 2 is provided with an accommodating space 21, and the accommodating space 21 is provided with a device that can rotate relative to the turntable 2. The weight wheel 3 and the weight wheel 3 are equipped with a weight 4, and the weight 4 rotates with the weight wheel 3, and rotates around the center of rotation of the weight wheel 3, that is, the center of the weight 4 is not in contact with the weight The rotation centers of the wheels 3 coincide, which makes the position of the weight 4 on the balance wheel 3 on the turntable 2 change when the balance wheel 3 rotat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap