Cast workpiece inner cavity automatic sand cleaning machine

A technology of sand cleaning machine and inner cavity, which is applied in the field of post-casting treatment, can solve problems such as difficulty in ensuring product quality, low work efficiency, and high labor intensity, and achieve the effects of quick and convenient sand cleaning, high work efficiency, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings, but the protection content of the present invention is not limited thereto.

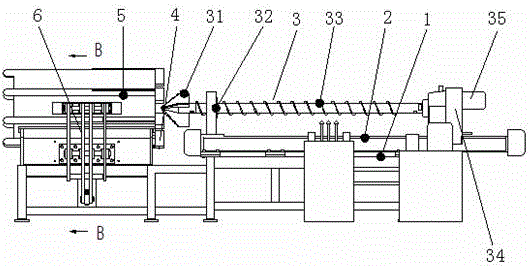

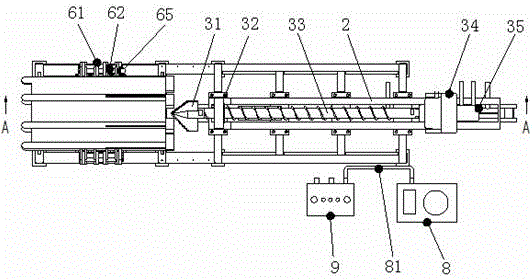

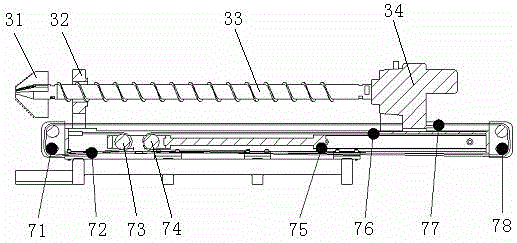

[0021] The automatic sand cleaning machine for casting workpiece inner chamber provided by the present invention comprises a frame 1, a guide rail 2 is arranged on the right end of the frame 1, and a screw feeding drill mechanism 3 is slid on the guide rail 2, and the left end on the frame 1 is opposite to each other. Equipped with front and rear clamping mechanism 6;

[0022] The screw feed drill mechanism 3 includes a screw rod 33 with a drill bit 31, a support frame 32 for supporting the head (left end) of the screw rod 3 on the frame 1, and the tail of the screw rod 33 is connected with the rotary power mechanism, and the rotary power mechanism Placed on the guide rail 2 on the frame 1, and connected to the feed drive mechanism 7; the rotary power mechanism includes a base 34 with a slide b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com