Device suitable for steel strip edge coiling

A steel strip coil and arc-shaped technology, which is applied in the field of steel strip production and processing, can solve the problems of inconvenient maintenance and complicated device structure, and achieve the effect of convenient maintenance and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

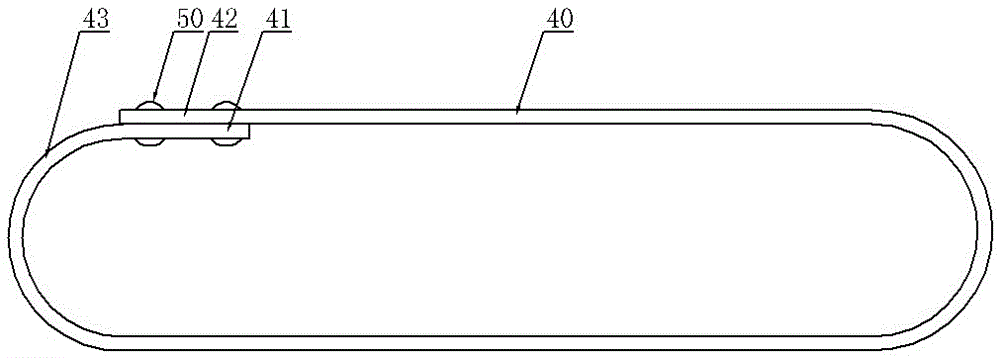

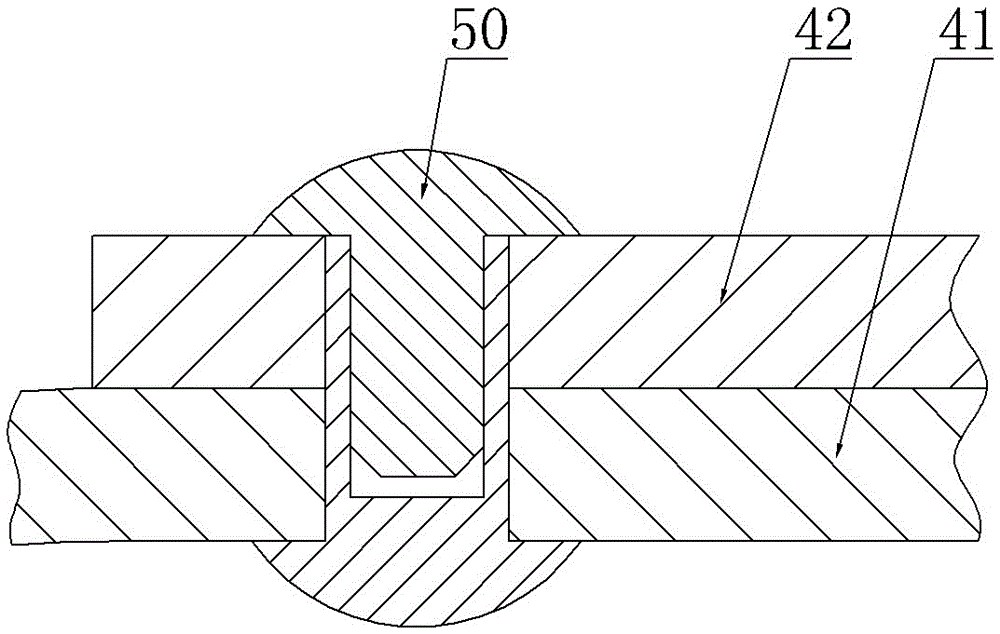

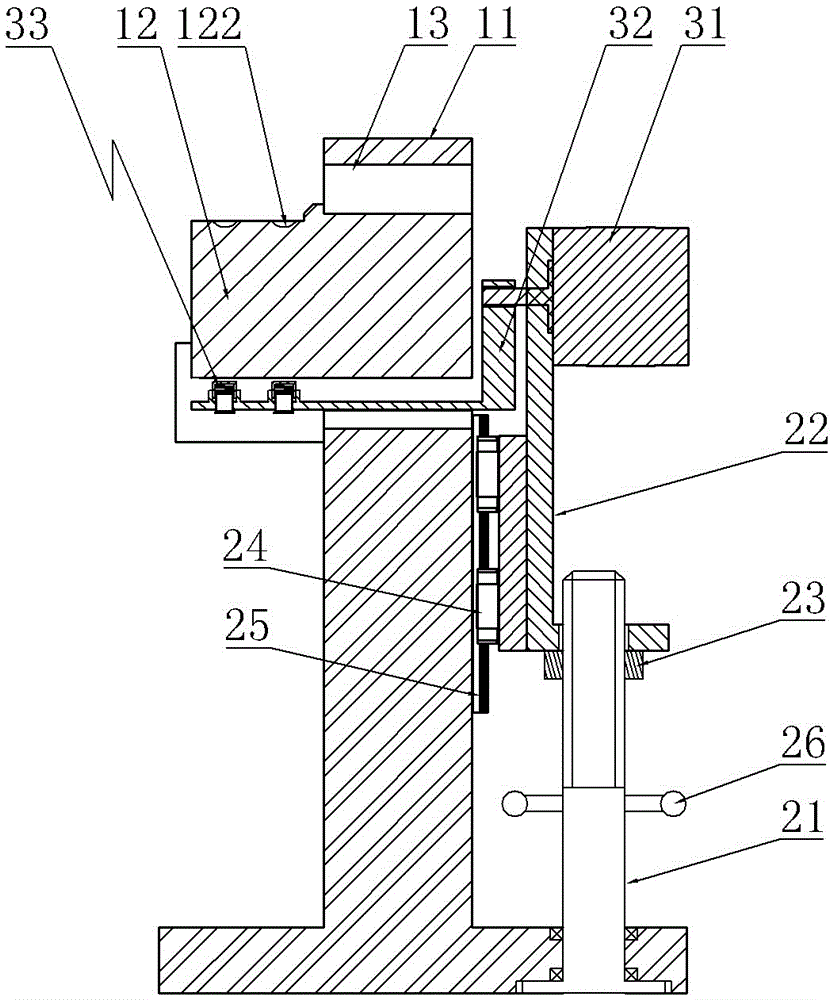

[0021] Such as Figure 3~Figure 6 As shown, it includes a support frame, a simulation block and a rolling mechanism;

[0022] The simulation block 12 is vertically fixed on the support frame 11, the side of the simulation block 12 perpendicular to the support frame 11 is composed of an arc-shaped curved surface 123 and a plane 121 connecting the top two ends of the arc-shaped curved surface 123, and the support frame 11 is located at the outer side of the side surface. There is an arc-shaped piercing groove 13 matching the arc-shaped curved surface and the plane;

[0023] The rolling mechanism includes a servo motor 31, an L-shaped connecting rod 32 and a pressing mechanism 33. The longitudinal part of the L-shaped connecting rod 32 is fixedly connected to the output shaft of the servo motor 31, and the transverse part of the L-shaped connecting rod 32 runs through an arc-shaped groove. , and protrudingly provided with a pair of tubular sliding tables 321, and each sliding ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com