A preparation method for nano-palladium-supported catalyst with exposed highly active {110} crystal faces

A {110}, high-activity technology, applied in the field of nanocatalysts, can solve the problems of limited Pd catalytic activity, few active sites, large Pd nanoparticle size, etc., and achieves good application prospects, simple preparation method, and multiple active sites Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Put 0.0405g PVP in a 50ml three-neck flask, add 10ml 0.13M glucose solution, reflux and stir in an oil bath at 150°C for 10min, keep at 150°C, add 10ml 7.3mM Na 2 PdCl 4 The solution was quickly added to a three-necked flask, and continued to react for 18 hours, then washed alternately with acetone and ethanol, and then dispersed in 10ml of ethanol to obtain Pd nanoparticles with exposed highly active {11 0} crystal planes.

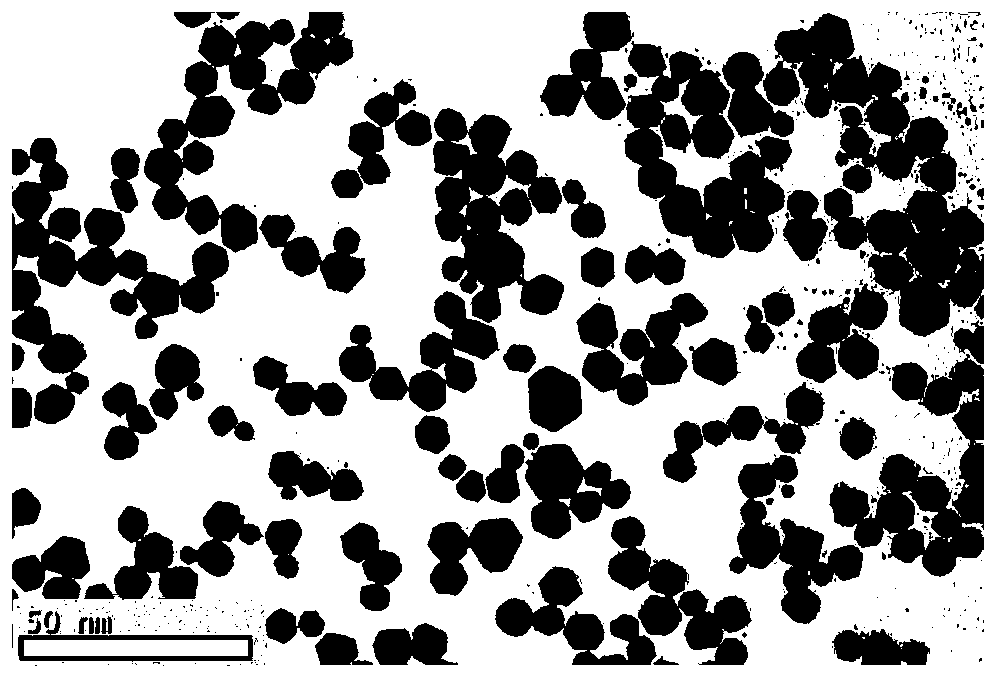

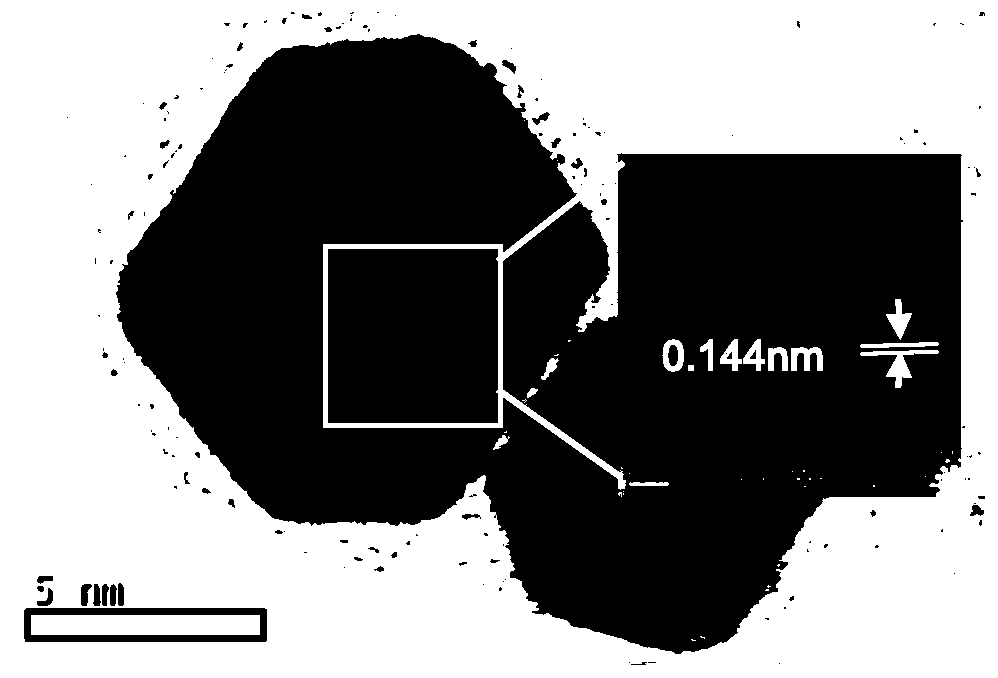

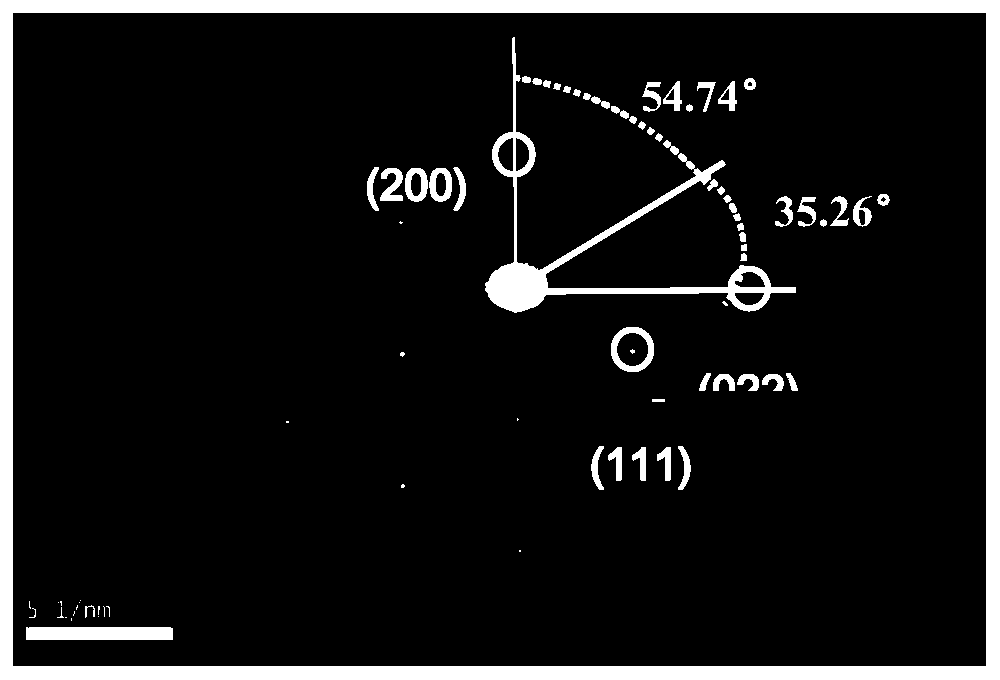

[0033] Depend on figure 1 It can be seen that the size of the prepared nanoparticles is less than 20nm, and the particles are uniformly dispersed. figure 2 and image 3 Compared with the standard electron diffraction pattern of {11 0} crystal system, it can be confirmed that the obtained nanoparticles are exposed to highly active {1 1 0} crystal planes. Figure 17 It can be confirmed that the obtained nanoparticles are Pd nanoparticles with exposed highly active {1 1 0} crystal faces.

Embodiment 2

[0034] Example 2: According to the preparation method of Example 1, the Pd nanoparticles exposed to the highly active {1 1 0} crystal face after centrifugal washing were dried in an oven at 80°C, and 0.1g was weighed with a microbalance and then dispersed in 5ml Deionized water, placed in a 10ml beaker, and then added 0.99g CeO 2 powder (Pd accounted for 1wt%), fully stirred at room temperature for 6h, washed alternately with acetone and ethanol, centrifuged, dried at 80°C, and calcined at 500°C for 3h in a muffle furnace to obtain Pd / CeO 2 The supported three-way catalyst is designated as sample 1.

Embodiment 3

[0038] Example 3: In this example, the reaction temperature is 180° C., and other steps are the same as in Example 1 to obtain Pd nanoparticles exposing highly active {1 1 0} crystal planes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com