Flat-plate hyperfiltration membrane component applicable to carrying out hyperfiltration membrane modification by electric field induction

An ultrafiltration membrane, flat plate technology, applied in ultrafiltration, membrane technology, semi-permeable membrane separation, etc., can solve the problem of insufficient stability of the combination of precoat and ultrafiltration membrane, and reduce water turbidity and permanganate. index, good corrosion resistance, and the effect of improving the service life of the membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] 1. Introduction to the structure of the flat ultrafiltration membrane module:

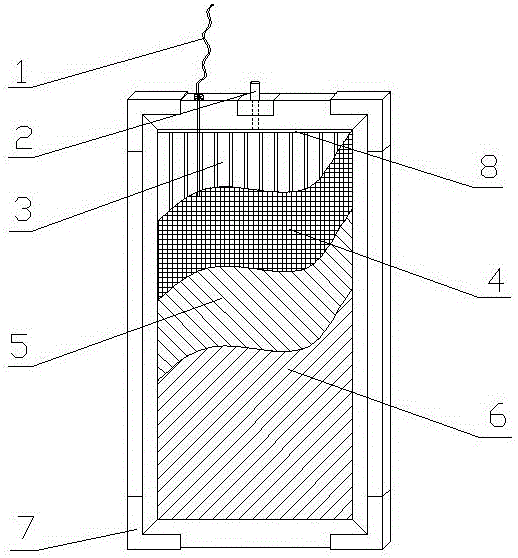

[0019] Such as figure 1 As shown, the ultrafiltration membrane 6 is clamped by the fixing clip 7. The ultrafiltration membrane 6 is a polyvinylidene fluoride ultrafiltration membrane with a nominal pore size of 0.1 μm. The fixing clip 7 is made of ABS resin.

[0020] A diversion cloth 5 is arranged in the inner chamber of the ultrafiltration membrane 6 , a graphite screen 4 with a density of 60 mesh is arranged in the inner chamber of the diversion cloth 5 , and a guide plate 3 is arranged in the inner chamber of the graphite screen 4 .

[0021] The graphite screen 4 is electrically connected to the inner end of a group of wires 1, the middle part of the wire 1 passes through the slit of the deflector 3, the outer end of the wire 1 is arranged on the outside of the ultrafiltration membrane 6, and then sealed in the ultrafiltration membrane 6 by epoxy resin On the fixing clip 7.

[0022] A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com