A kind of taro peeling assembly line

An assembly line and taro technology, applied in the peeling of vegetables or fruits, food science, applications, etc., can solve the problems of long contact time, skin itching, low efficiency of manual peeling, etc., to improve peeling efficiency and peeling strength strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following embodiments are combined with the accompanying drawings to elaborate on the present invention.

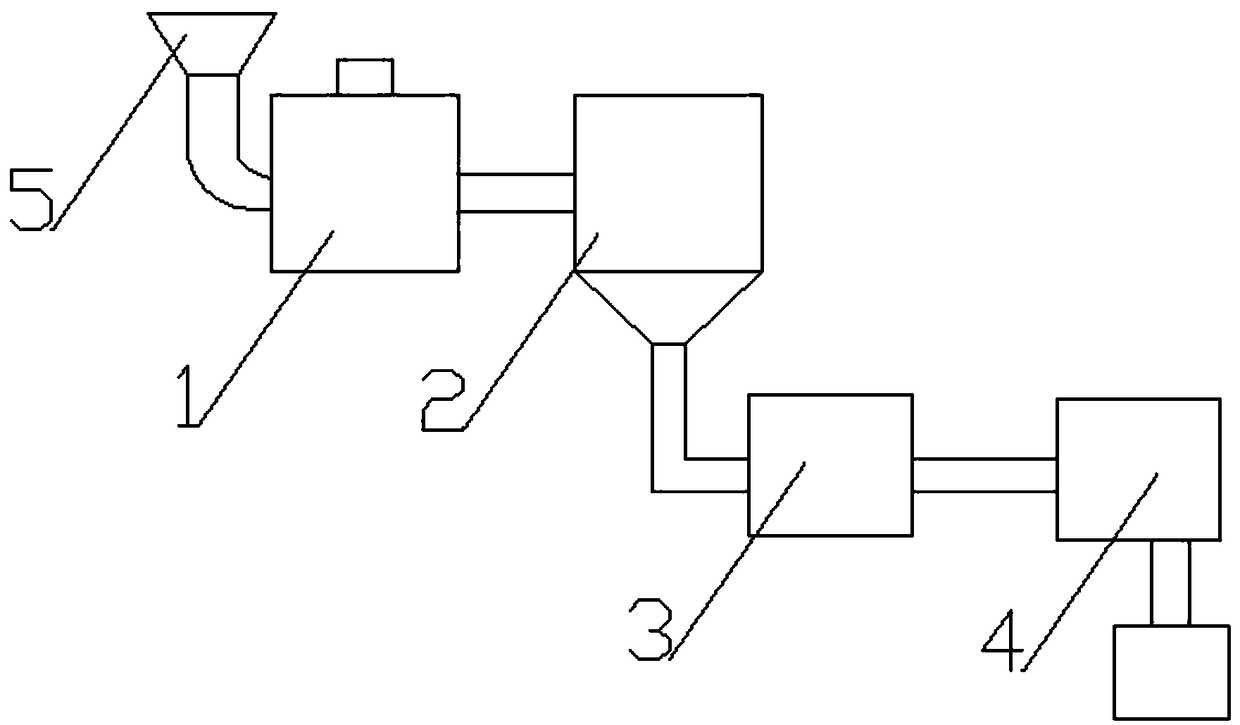

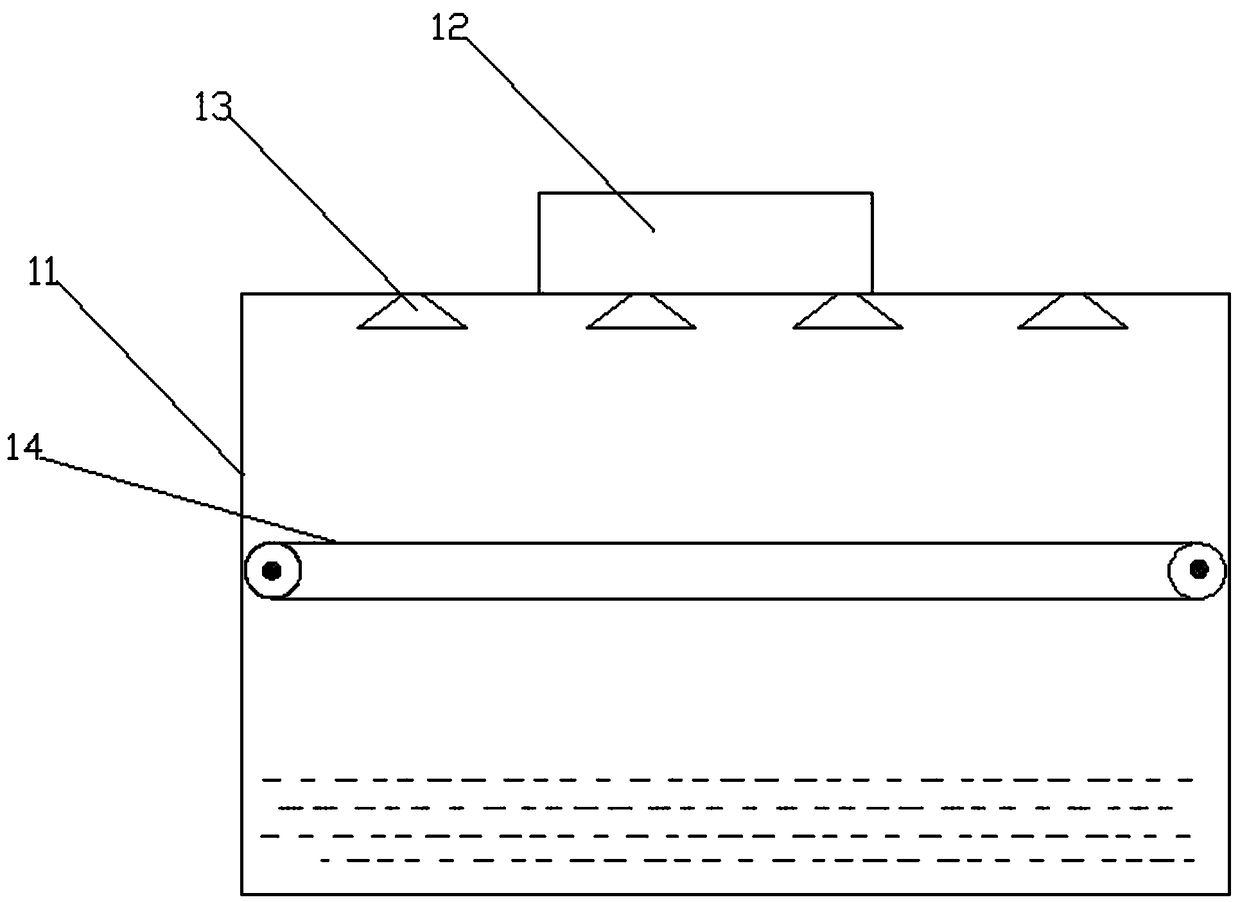

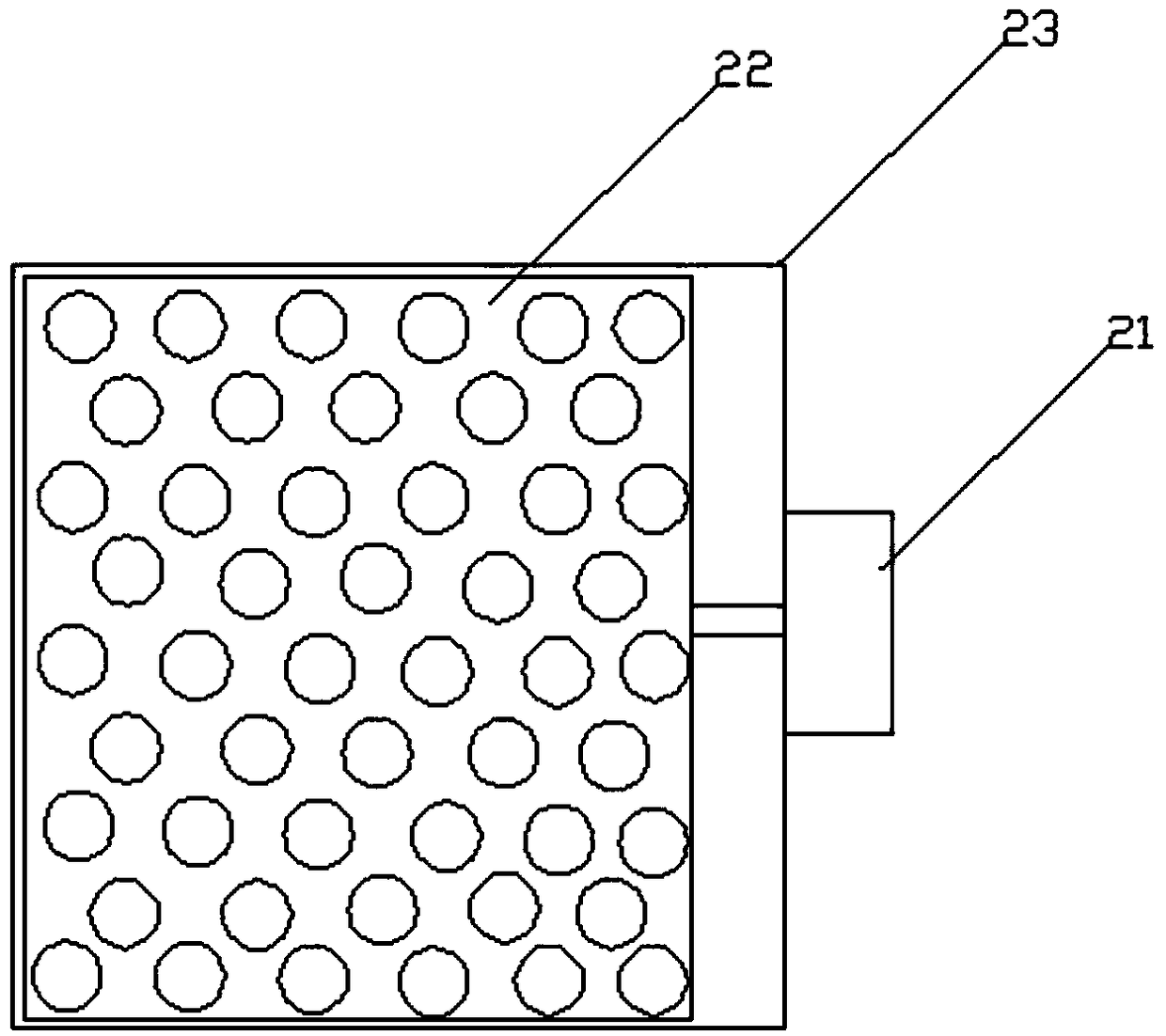

[0038] figure 1 For the structural representation of a kind of taro peeling assembly line of the present invention, please refer to figure 1 As shown, a kind of preferred taro peeling assembly line is shown, including cleaning section 11, screening section 2, drying section 3, peeling section 4 and control section, and described cleaning section 11 is connected with the feeding port 5 of taro , Clean the surface of the taro and remove the silt on the surface. The drying part 3 is connected with the cleaning part, and the taro input from the cleaning part is dried to dehydrate the surface of the taro, and then the taro is sent to the screening part 2, and the taro is screened, and the oversized taro is sieved Then the taro with quali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com