Novel corn cob granary

A technology of corn cobs and stacks, which is applied in the field of new corn cobs stacks, can solve the problems of insufficient drying time for corn cobs, poor ventilation and heat dissipation, and moldy corn cobs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

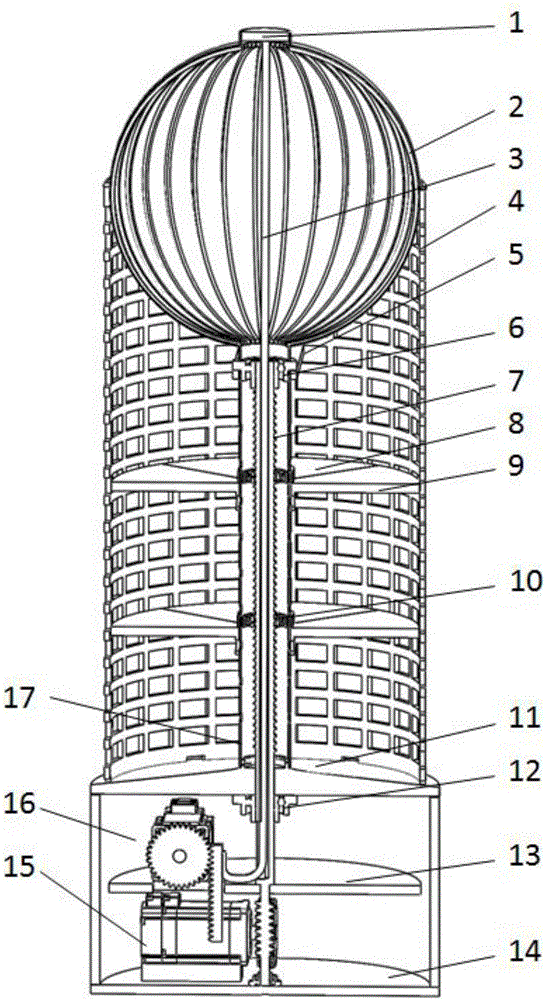

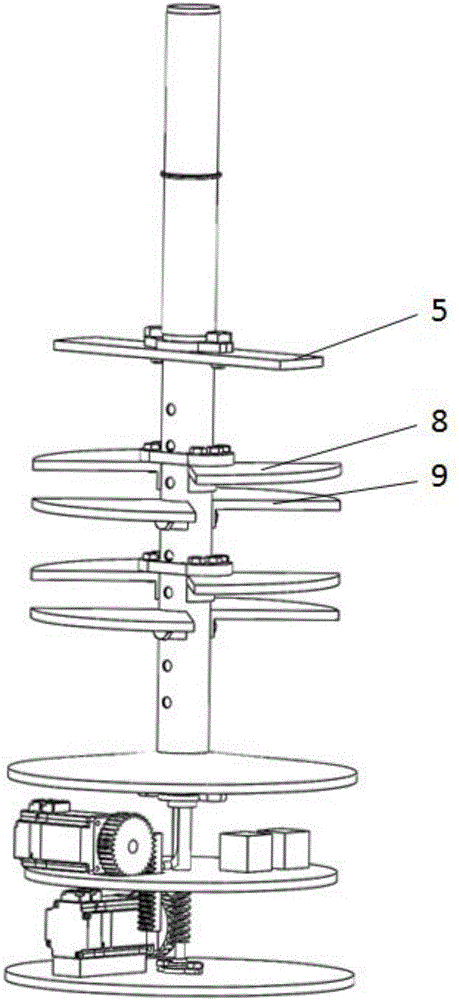

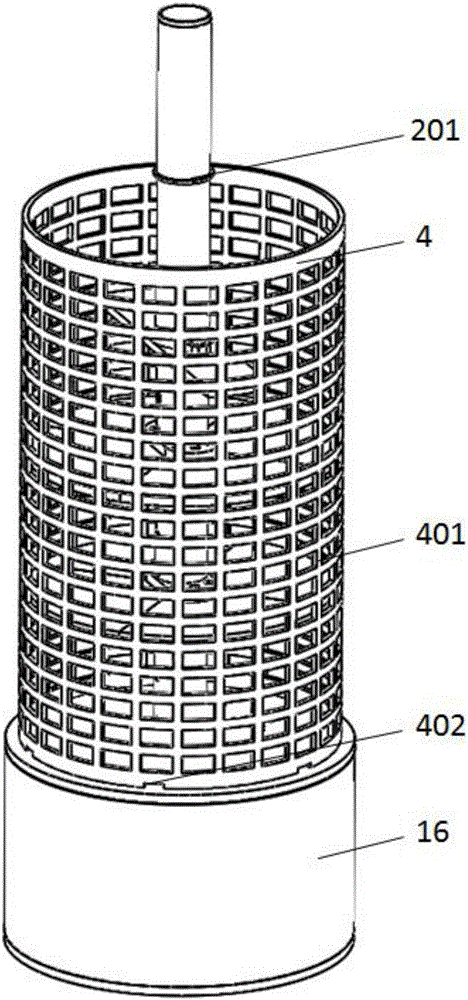

[0026] Such as Figure 1-11 As shown, a new type of corncob stack includes a top cover 1, a rain and snow sensor 101, a rain shielding device 2, a rain shielding ring 201, a retractable rod 202, a lower bracket 203, an upper bracket 204, a waterproof cloth 205, a pull rod 3, Stack 4, grid 401, drainage hole 402, connecting plate 5, first base 6, lead screw 7, moving plate 8, moving plate circular hole 801, moving plate arc plate 802, fixed plate 9, fixed plate arc Plate 901, fixed plate round hole 902, lead screw nut 10, lead screw nut round hole 1001, ring hole 1002, chassis 11, chassis round boss 1101, chassis round hole 1102, second base 12, rotating disc 13, bottom Frame 14, driving device 15, gear 1501, rack 1502, first stepper motor 1503, second stepper motor 1504, worm gear 1505, worm screw 1506, shell 16, inner barrel 17, inner barrel round hole 1701, inner barrel internal thread 1702, The controller 18, the power supply 19, and the third base 20 are characterized in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com