Harvester seed conveying device

A conveying device and harvester technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of reducing service life, increasing grain level auger load, and grain level auger blockage, etc. Low cost and the effect of preventing grains from scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

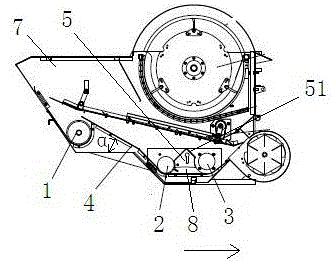

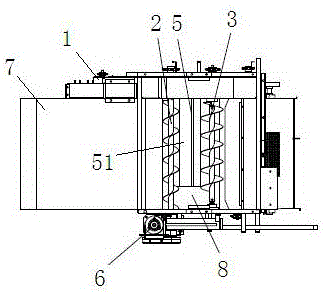

[0016] In this example figure 1 The direction pointed by the middle arrow is the front, otherwise it is the back.

[0017] Such as figure 1 and figure 2 As shown, the grain conveying device of the present invention is arranged on the lower side of the vibrating screen of the harvester and is positioned at the bottom of the frame. The grain conveying device includes a residual horizontal auger 1, a first grain auger 2, a second grain auger 3, a grain slide plate 4, an intermediate grain guiding body 5 and a grain lifting auger 6, and the residual horizontal auger 1 is laterally supported on On the rear side of the frame 7, the first grain auger 2 and the second grain auger 3 are horizontally and parallel supported on the front side of the frame 7, and the grain slide plate 4 is obliquely placed between the residual horizontal auger 1 and the first grain auger 2 , Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com